Lead-zinc integrated smelting furnace and method thereof for recovering lead and zinc

A smelting furnace, lead-zinc technology, applied in the field of integrated lead-zinc integrated smelting furnace that directly recovers lead and zinc, can solve the problems of discontinuous process, large investment, lead vapor leakage pollution, etc., to improve safety and avoid environmental pollution Pollution and the effect of reducing construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

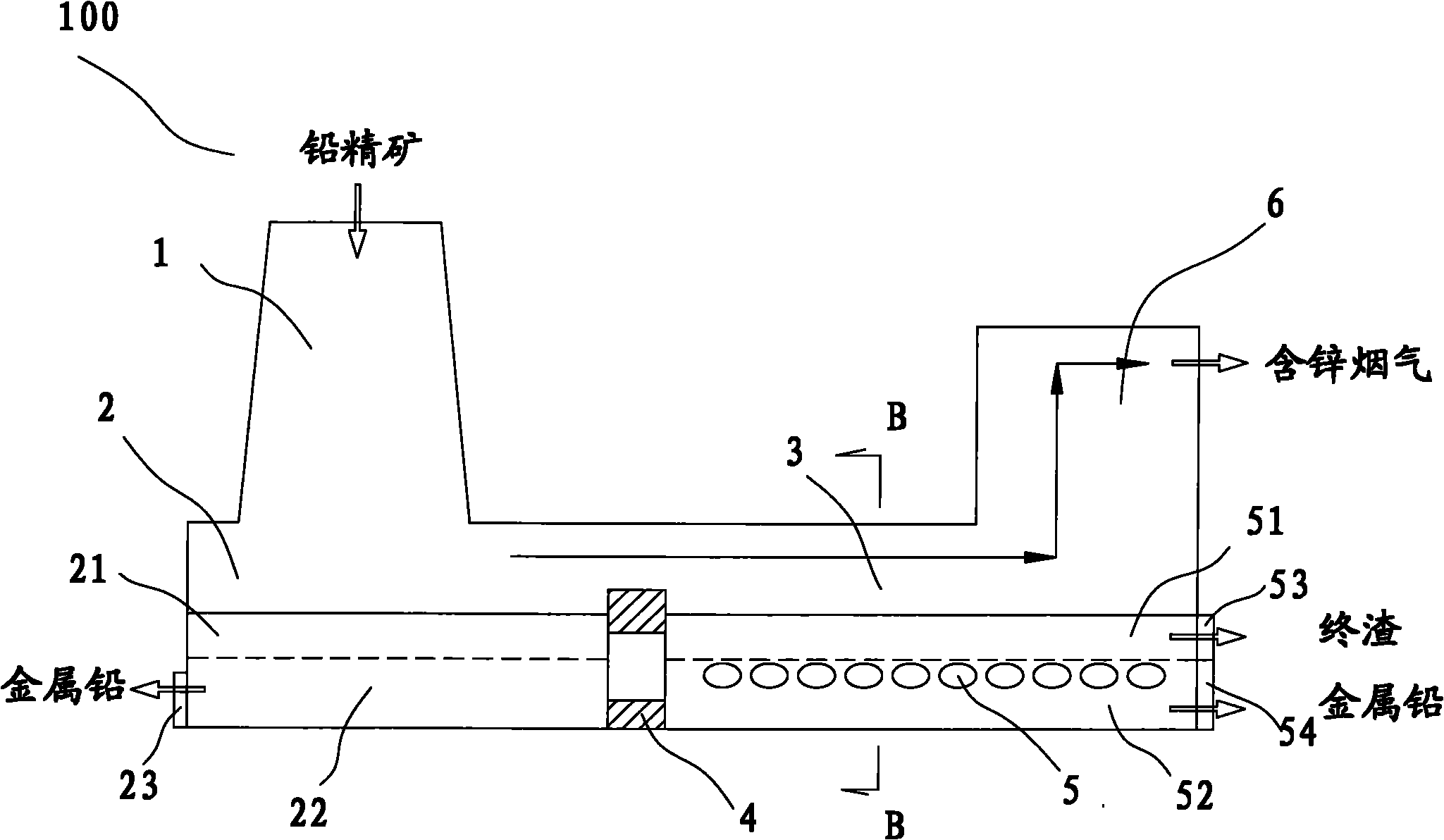

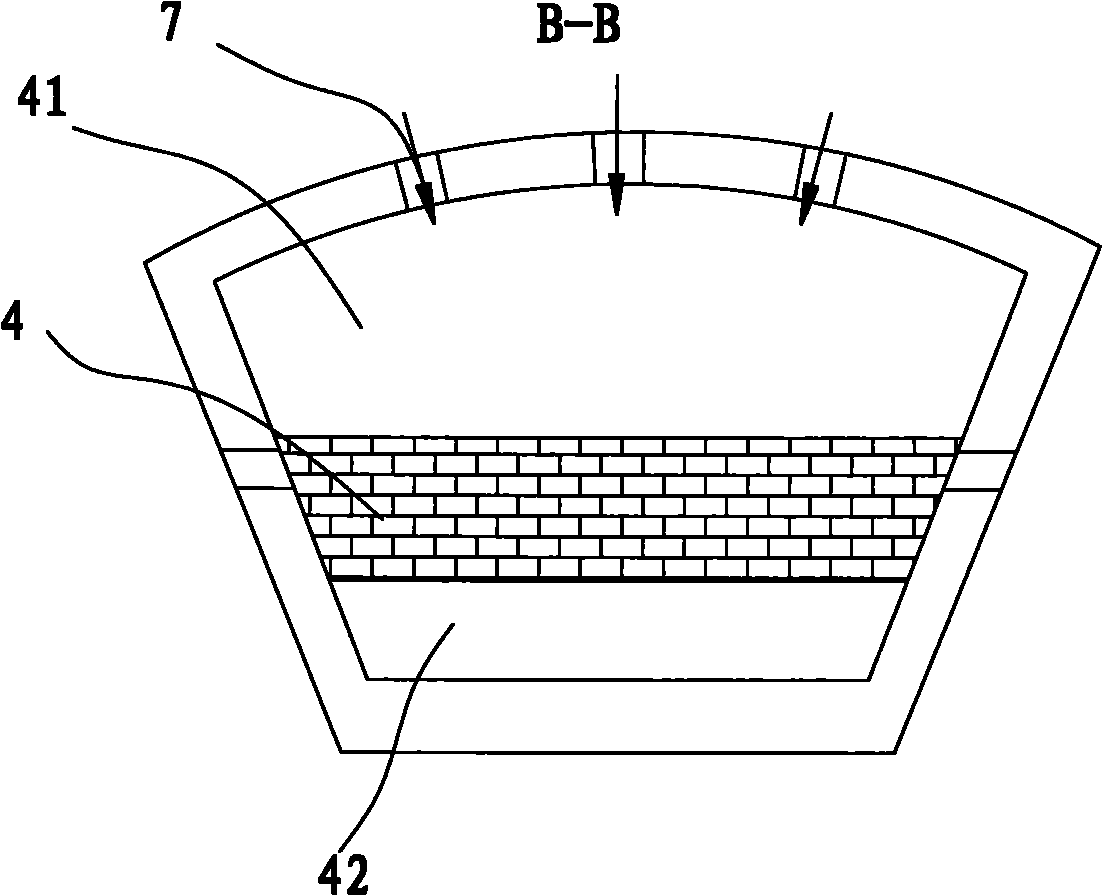

[0034] figure 1 A schematic diagram of an integrated lead-zinc smelting furnace 100 according to an embodiment of the present invention is shown. Such as figure 1 As shown in , according to an embodiment of the present invention, the lead-zinc integrated smelting furnace 100 includes: a reaction tower 1; The melt that falls after the reaction in the middle is divided into a slag layer 21 and a lead layer 22 in the sedimentation tank 2; a reduction tank 3, the reduction tank 3 is set adjacent to the sedimentation tank 2 and separated by a separator 4 , the reduction tank 3 is in fluid communication with the bottom of the sedimentation tank 2; a reductant supply unit 5 corresponding to the reduction tank 3, the reductant supply unit 5 is arranged on the furnace body of the reduction tank 3, to When the temperature of the reduction tank 3 is maintained within a predetermined temperature range, a reducing agent is supplied into the reduction tank 3 in such an amount that the lea...

no. 2 example

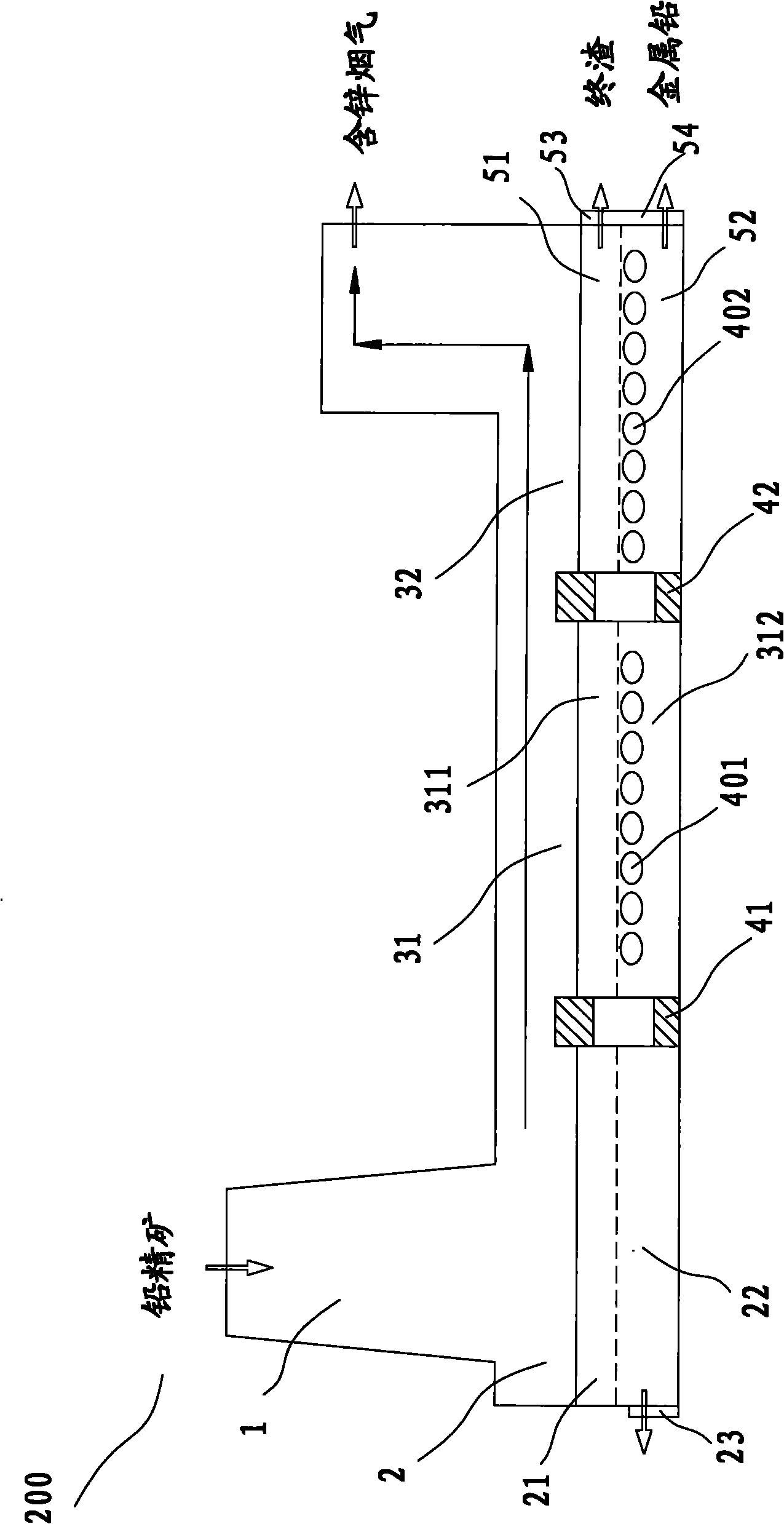

[0045] figure 2 A schematic diagram of an integrated lead-zinc smelting furnace 200 according to another embodiment of the present invention is shown. The lead-zinc integrated smelting furnace 200 includes: a reaction tower 1; a sedimentation tank 2, the sedimentation tank 2 is integrally arranged at the lower part of the reaction tower 1, and accommodates the melt falling from the reaction tower 1 after reaction, the melt Be divided into slag layer 21 and lead layer 22 in sedimentation tank 2; Reduction tank 31,32, described reduction tank 31,32 is arranged adjacent to sedimentation tank 2 and separated by separator 41,42, and described reduction tank 31 , 32 are in fluid communication with the bottom of the sedimentation tank 2; the reductant supply units 401, 402 corresponding to the reduction tanks 31, 32, the reductant supply units 401, 402 are respectively arranged in the reduction tanks 31, 32 On the furnace body, when the temperature of the reduction pools 31, 32 is ...

example

[0065] The following is an example of an experimental lead-zinc integrated smelting furnace (with an annual output of 30,000 tons / year of crude lead) in a factory in Yunnan, China, to describe the above-mentioned technology for directly recovering lead and zinc from the slag of the integrated lead-zinc smelting furnace. The composition of the lead concentrate used in the integrated smelting furnace is as follows:

[0066] Pb 50%, S 18%, Zn 3%, Cu 0.5%, Fe 15%, Ag 3000g / t.

[0067] The specific process steps are as follows:

[0068] (1) The powdery lead sulfide concentrate with 8% water content before drying and 0.3% water content after drying is sprayed into high-temperature reaction through a nozzle (not shown) together with oxygen containing 90% oxygen in the air supply and 25° C. of air supply temperature In tower 1, the inner diameter of the vortex furnace reaction tower is 3.0m and the height is 6.5m. The input of oxygen is controlled so that the oxidation rate of lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com