TFT-LCD ( Thin Film Transistor-Liquid Crystal Diode) array substrate and manufacture method thereof

A technology of an array substrate and a manufacturing method, which is applied in the field of TFT-LCD array substrate and its manufacturing, can solve the problems of increasing the occurrence rate of defects, increasing the number of mask plates, reducing the yield rate, etc., and achieves shortening process time, simplifying process steps, improving The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

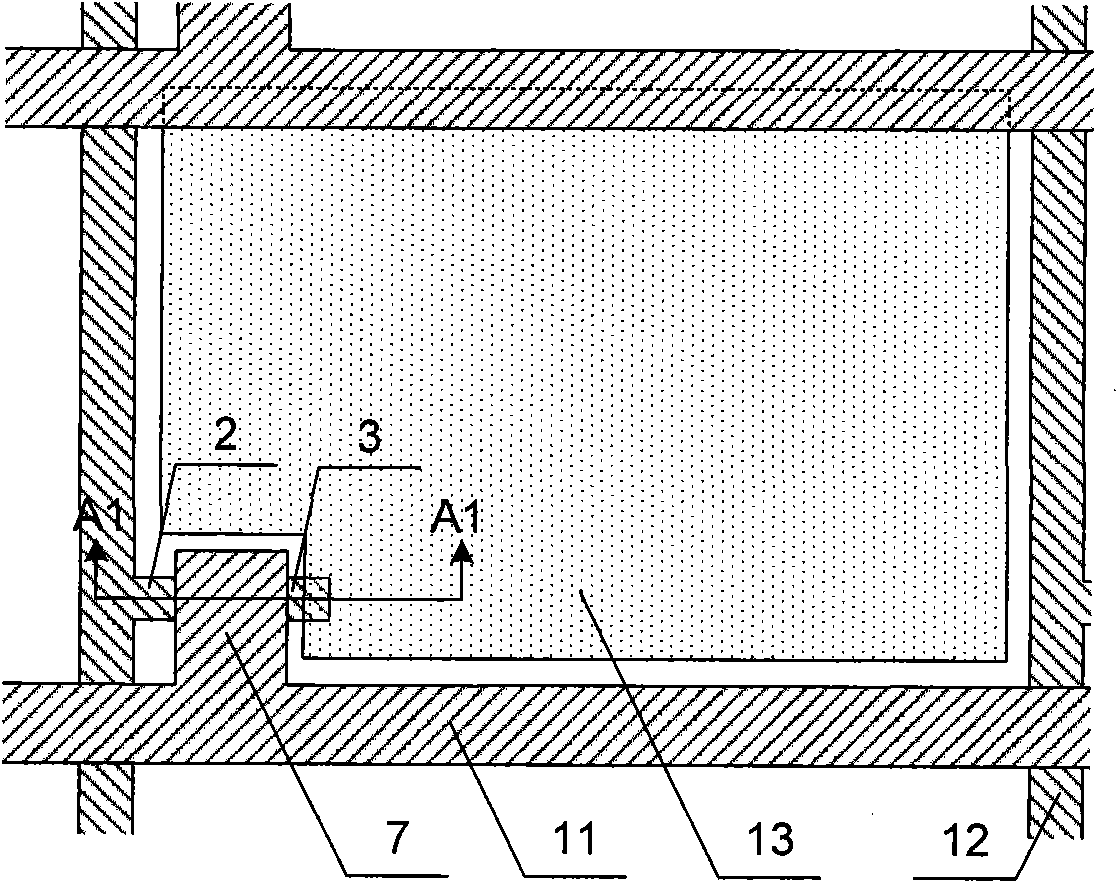

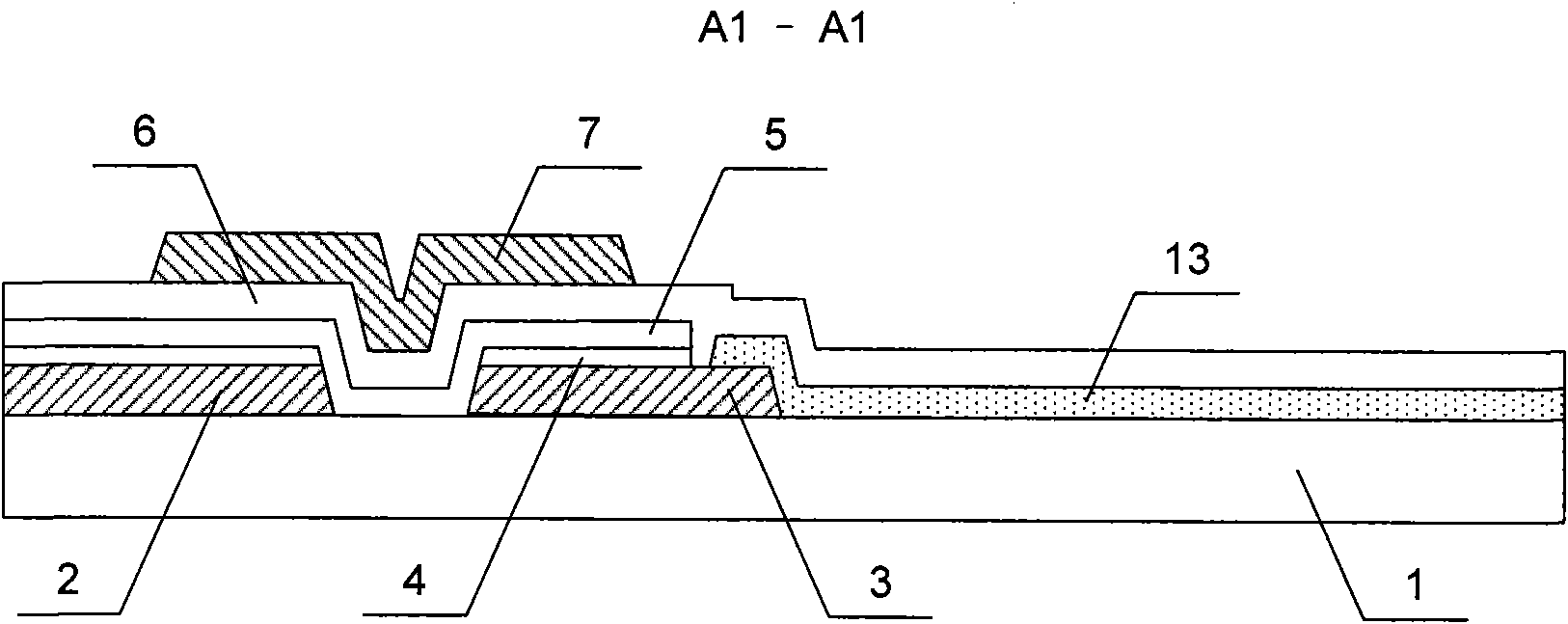

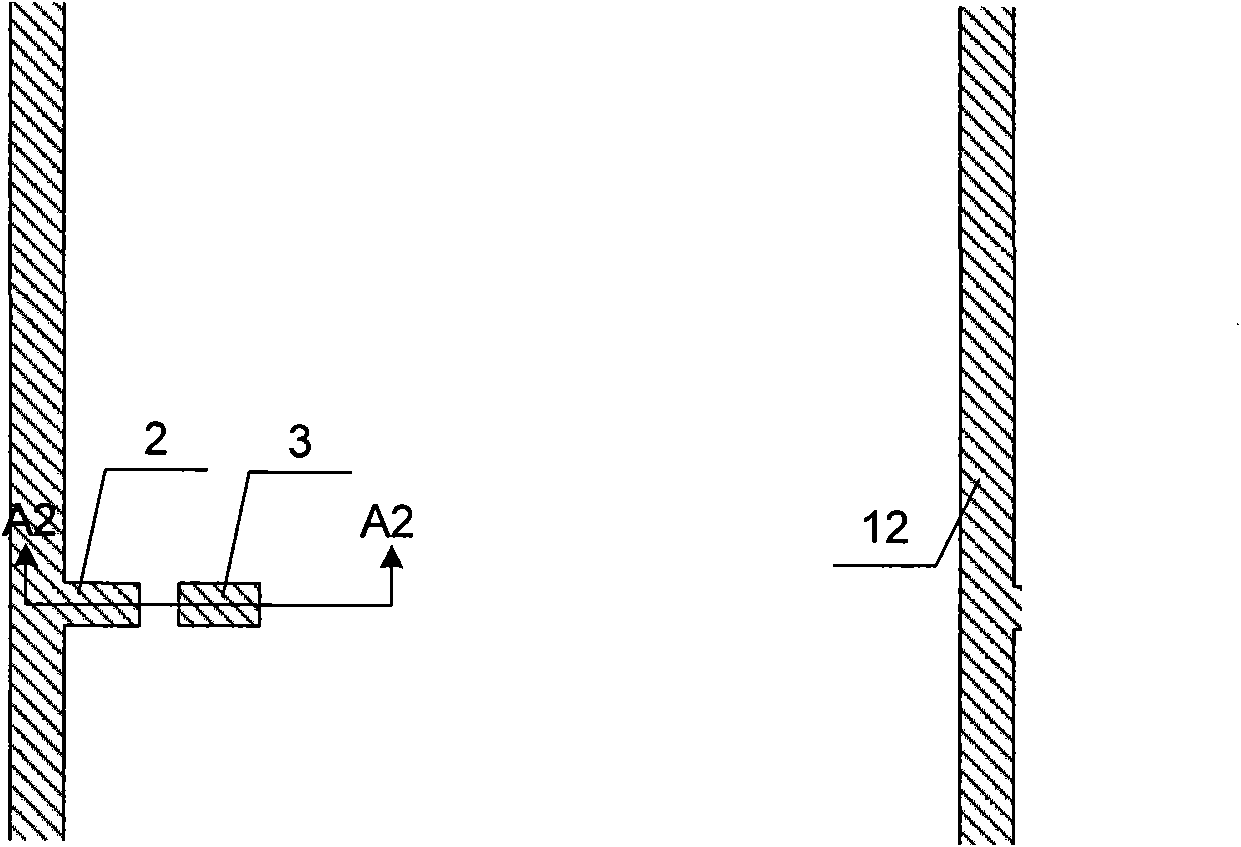

[0075] figure 1 It is a plan view of the first embodiment of the TFT-LCD array substrate of the present invention, reflecting the structure of a pixel unit, figure 2 for figure 1 Sectional view of A1-A1 in the middle. Such as figure 1 with figure 2 As shown, the main structure of the TFT-LCD array substrate in this embodiment includes gate lines 11, data lines 12, pixel electrodes 13 and thin film transistors, the gate lines 11 and data lines 12 perpendicular to each other define pixel regions, and the thin film transistors and pixel electrodes 13 is formed in the pixel area, the gate line 11 is used to provide the turn-on signal to the thin film transistor, and the data line 12 is used to provide the data signal to the pixel electrode 13 . Specifically, the TFT-LCD array substrate of this embodiment includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com