Manufacturing method of subminiature MEMS gyroscope sensor

A manufacturing method and gyroscope technology, applied in chemical instruments and methods, instruments, manufacturing microstructure devices, etc., can solve problems such as no breakthrough technology, and achieve the effect of saving area, less equipment investment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

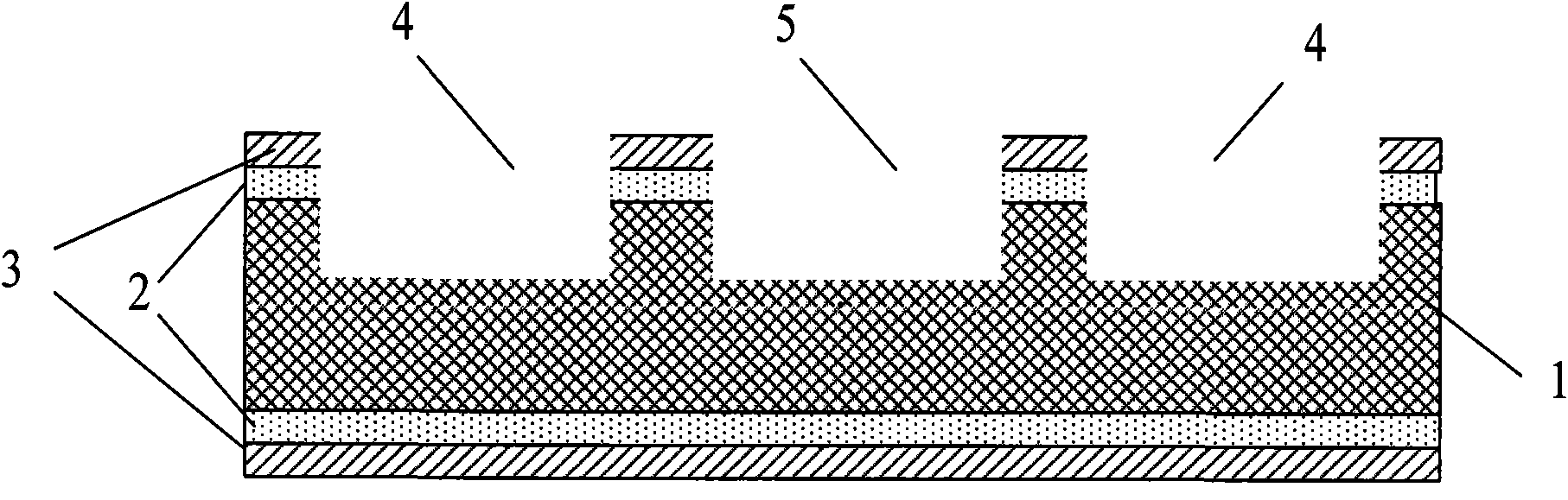

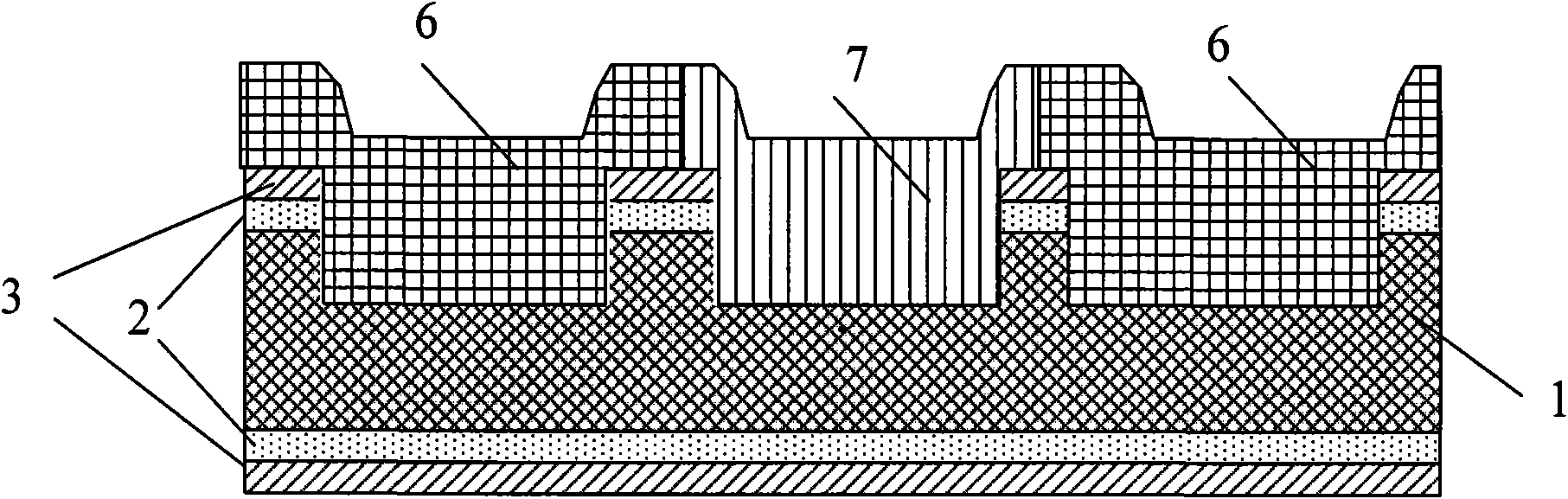

[0031] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0032] The manufacturing method of the ultra-small MEMS gyroscope sensor involved in the present invention is to embed a metal with a density higher than that of silicon in the silicon chip by etching and electroplating on the silicon chip / wafer, and then bond it to the silicon or glass substrate , and finally release the movable structure according to the normal silicon micromachining method, wherein the ultra-small MEMS gyroscope sensor is a MEMS inertial sensor, and its manufacturing method specifically includes the following steps:

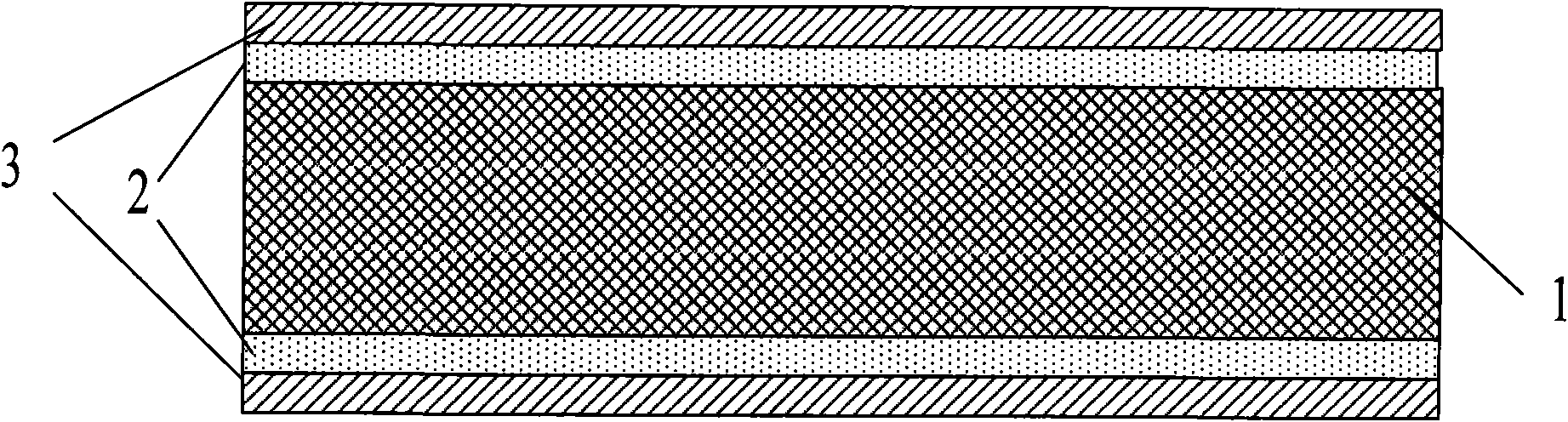

[0033] A1, such as figure 1 As shown, the deposition step is first: a MEMS wafer 1 is provided, and both sides of the silicon substrate are polished, or a wafer polished on both sides is directly purchased as the material of the MEMS wafer 1 . Growth or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com