Micro-fluid reactor, using method and application thereof

A microfluidic reactor and microreaction technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of complex system structure, cumbersome control, affecting the promotion and application of microfluidic reactors, etc. , to achieve the effect of simplifying the operation process, saving manpower and cost, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

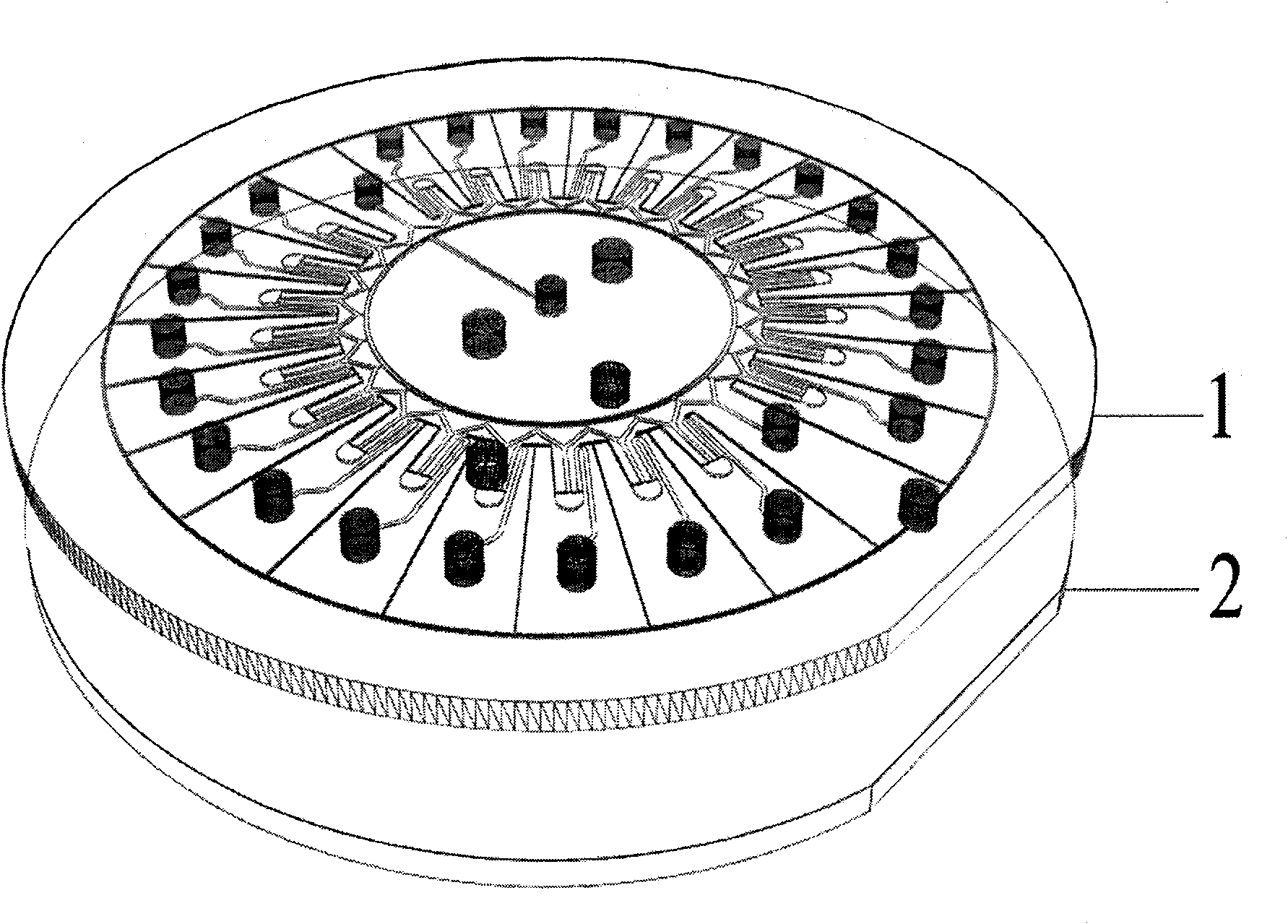

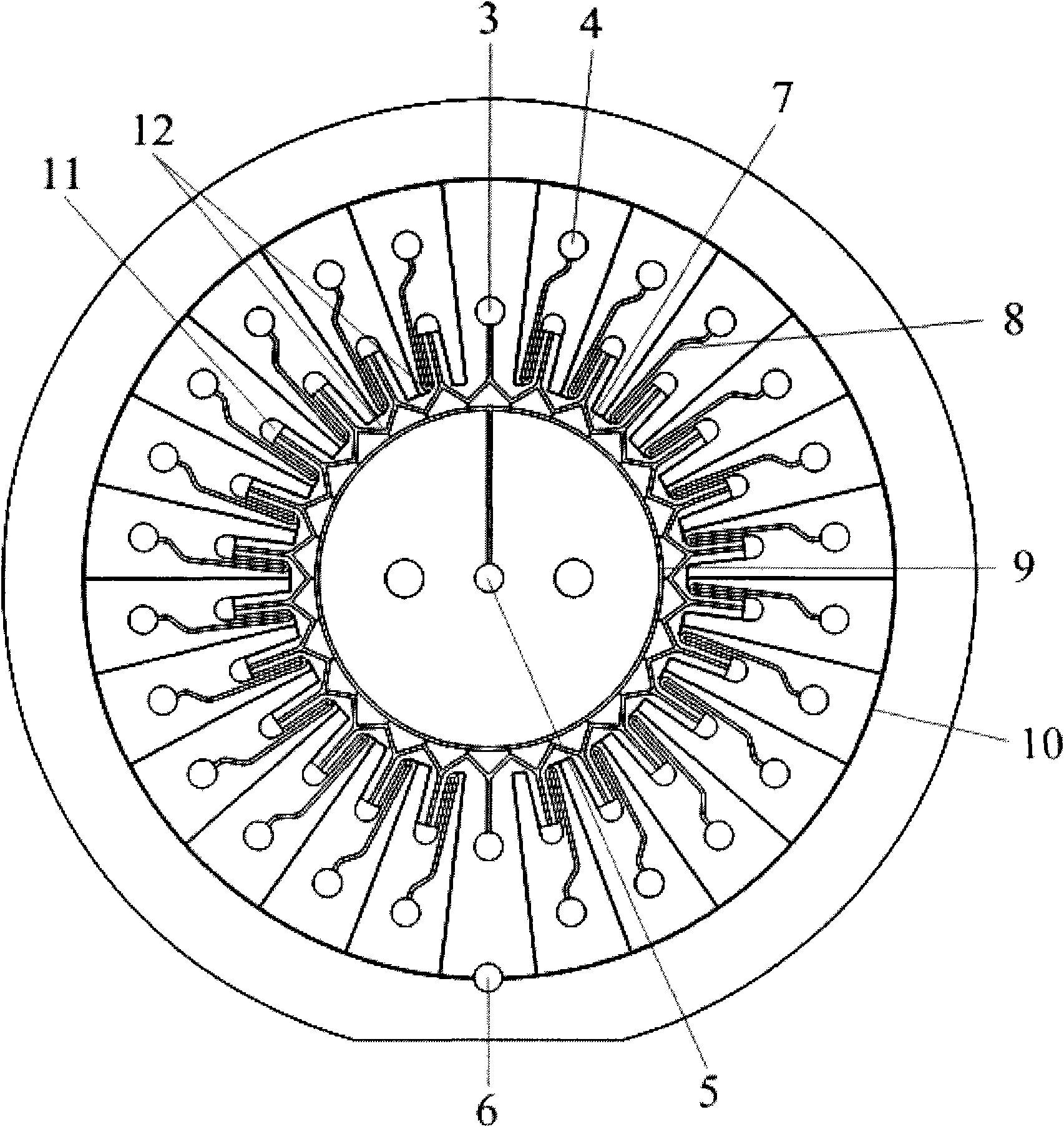

[0016] Such as figure 1 Shown, the microfluidic reactor of the present invention is a kind of composite disc-shaped microfluidic chip, and this chip is processed with microchannel and has the substrate 1 of hydrophobic property and the flat substrate of another surface with hydrophilic property by one surface 2 bonded structure; including main injection hole 3, branch injection hole 4, central ventilation hole 5, peripheral ventilation hole 6, main sampling micropipe 7, branch sampling micropipe 8, central ventilation micropipe 9, branch Structures such as ventilation micro-channel 10 and micro-reaction chamber 11 (such as figure 2 shown); wherein the cross-sectional aspect ratio of the main sampling micropipe 7 and the branch sampling micropipe 8 is greater than 1.5, ensuring that the hydrophilic force in the micropipe is greater than the hydrophobic force, so as to realize the microfluidic reactor based on capillary action At the same time, the micro-reaction chamber 11 wi...

Embodiment 2

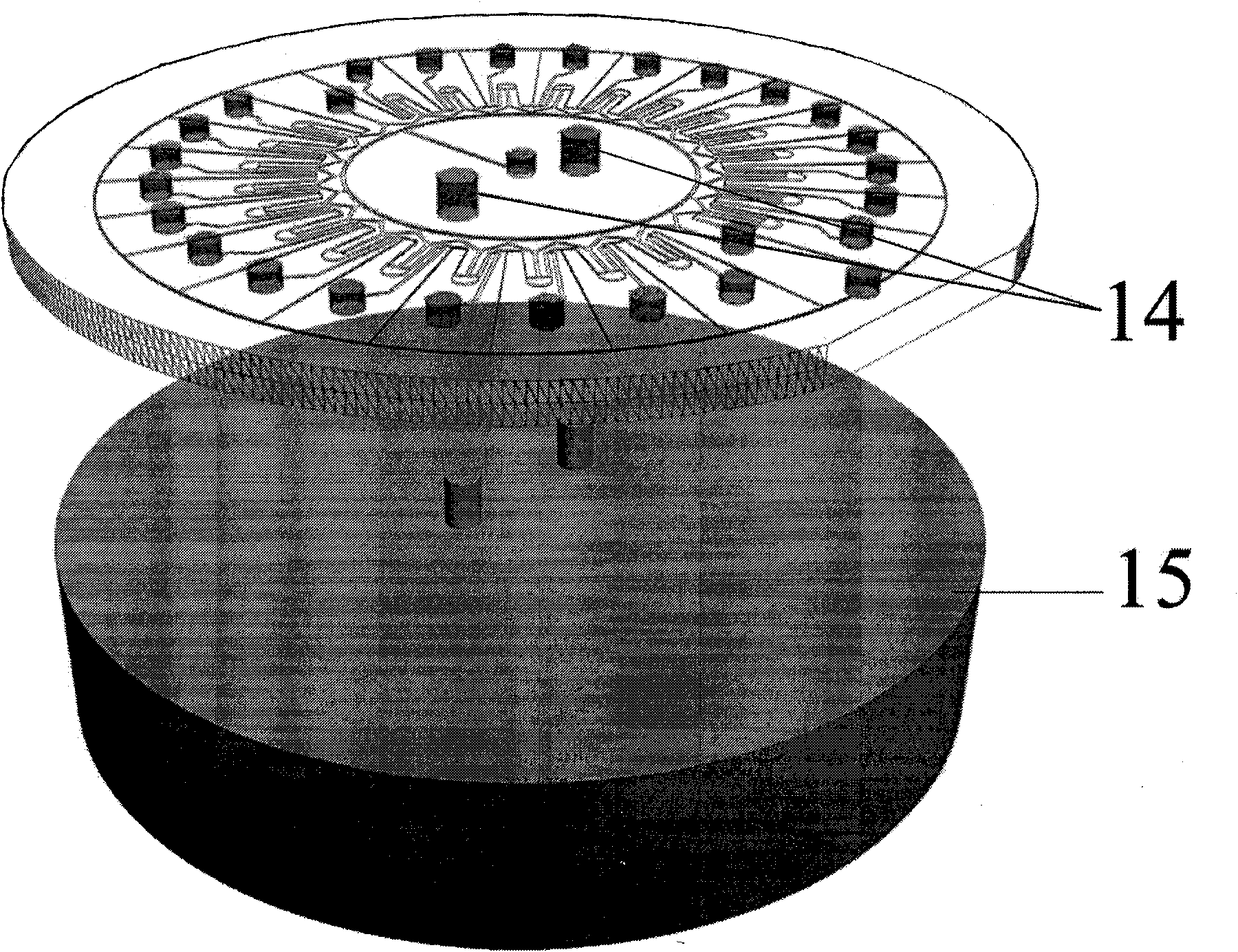

[0019] The microfluidic reactor prepared in Example 1 is applied to the high-throughput screening of protein crystallization conditions. The method is as follows: firstly, the protein solution to be crystallized is dropped into the main injection hole 3, and various crystallization ratios and concentrations The reagent is added to each branch sampling hole 4, and then the microfluidic reactor after the sampling is completed is placed and fixed on the centrifuge 15 through the chip fixing hole 14, and the chip is rotated at a high speed, and each section of the main sampling pipeline is separated by centrifugal force. The protein solution and the crystallization agent of each branch sampling pipeline are distributed to each micro-reaction chamber 11 for mixing, and then silicone oil is added into the central vent hole 5, and the microfluidic reaction is performed after the silicone oil fills the central vent pipe under the action of capillary force. The microfluidic reactor is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com