Method and die for forward extrusion and variable diameter bending extrusion of magnesium alloy semi-solid billets

An extrusion die, semi-solid technology, applied in metal extrusion die and other directions, can solve the problems of product quality decline, long extrusion time, low production efficiency, etc., to achieve uniform deformation, large deformation, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

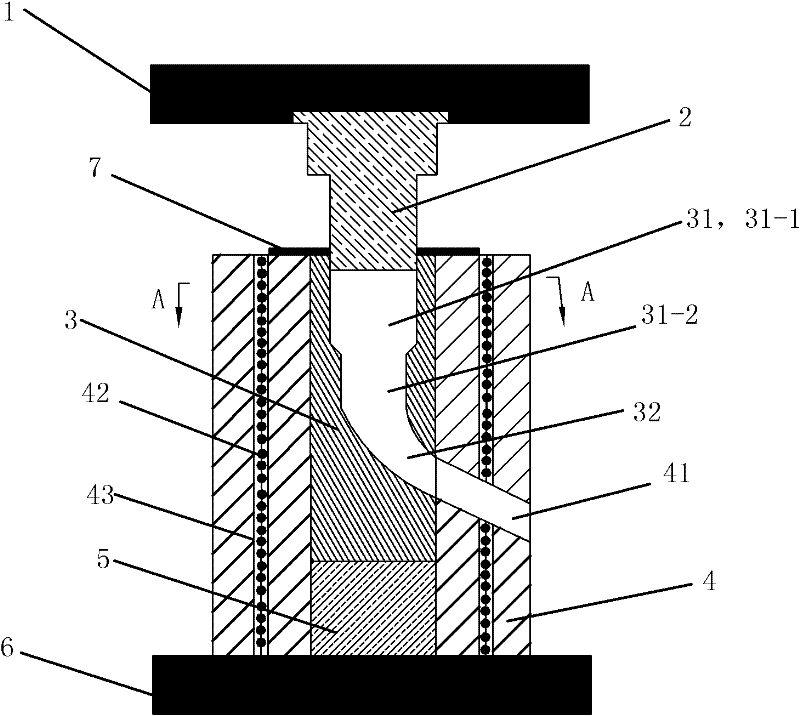

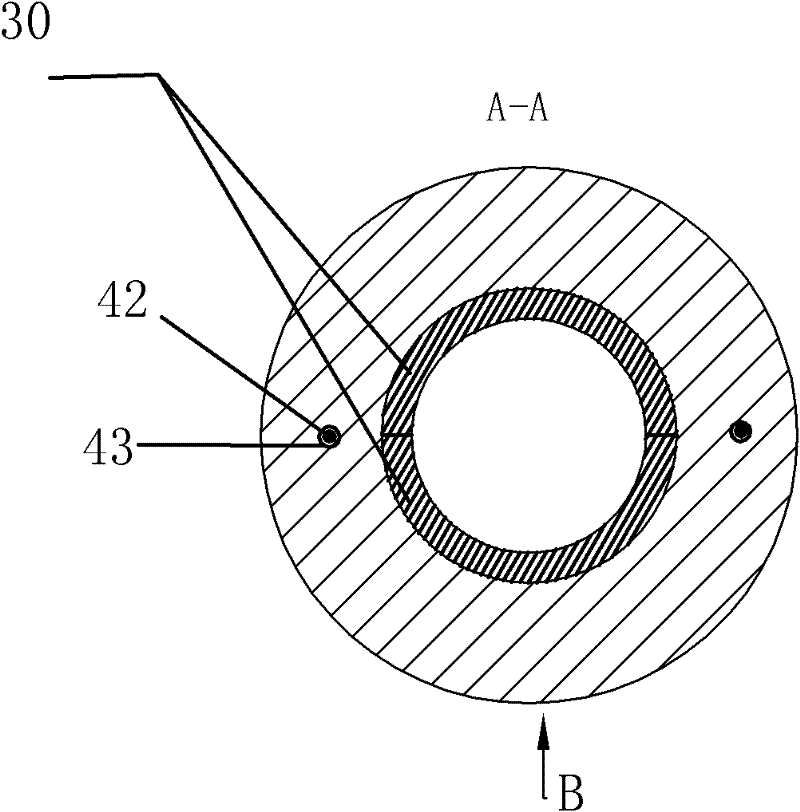

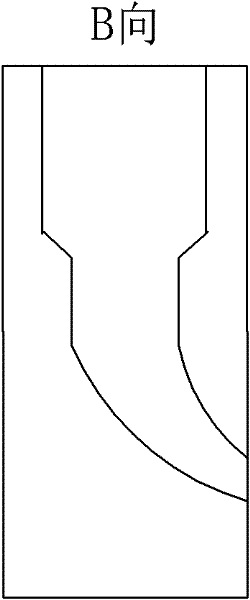

[0016] (embodiment 1, the forward extrusion of magnesium alloy semi-solid billet and variable-diameter bending extrusion die) see Figure 1 to Figure 3 , the forward extrusion and variable diameter bending extrusion processing dies for preparing magnesium alloy semi-solid billets in this embodiment include an upper template 1, a punch 2, a die 3, a die cover 4, a heating wire 42, a ceramic tube 43, a pad Block 5, lower template 6 and pressing plate 7.

[0017] The die cover 4 is seated and fixed on the lower template 6, and the lower surface of the die cover 4 is in contact with the upper surface of the lower template 6; the lower part of the space in the middle of the die cover 4 places a spacer 5. The die 3 is provided with a feeding port located at the upper end, the die 3 is arranged above the cushion block 5, and is located in the middle space of the die set 4, and the die 3 and the die set 4 are in clearance fit; the punch 2 is stepped , its upper end is fixedly connect...

Embodiment 2

[0021] (Embodiment 2, the forward extrusion and variable-diameter bending extrusion method of preparing magnesium alloy semi-solid billet) see Figure 4 to Figure 7 , the present embodiment prepares the used extrusion die of the forward extrusion of magnesium alloy semi-solid billet and the extrusion die of variable diameter corner extrusion method, adopts the die obtained in embodiment 1, and what this embodiment handles is AZ91D magnesium alloy cast billet, The method for preparing the magnesium alloy semi-solid billet comprises the following steps: 1. Machining of the magnesium alloy billet: the magnesium alloy cylindrical billet is processed into a cylindrical billet corresponding to the inner diameter of the upper end of the die 3, the diameter of the billet is 50mm, and the height is 120mm.

[0022] ② Pre-deformation of the billet: Preheat the cylindrical billet machined in step ① in a box-type resistance furnace at a preheating temperature of 280°C and keep it warm for ...

Embodiment 3

[0028] (Embodiment 3, the forward extrusion and variable-diameter bending extrusion method of preparing magnesium alloy semi-solid billet) see Figure 8 , the difference between this embodiment and embodiment 2 is: in step ②, the billet processed by step ① is preheated in a box-type resistance furnace, the preheating temperature is 300 ° C, and the heat preservation is 15 minutes, and the extrusion die is preheated When hot, the mold temperature is 240°C, and the pre-deformation temperature of the blank, that is, the temperature of the blank during the pre-deformation process, is 300°C.

[0029] Compared with embodiment 2, the present embodiment increases the pre-deformation temperature, which will make the average grain diameter larger, but the present embodiment reduces the pre-deformation holding time, and correspondingly makes the average grain diameter smaller; compared with embodiment 1, The raising of present embodiment pre-deformation temperature and the reduction of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com