Method for preparing MoS2 microspheres by solvent hot method

A solvothermal method and microsphere technology, applied in the direction of molybdenum sulfide, can solve problems such as unfavorable large-scale production and application, harsh production conditions, high synthesis temperature, etc., and achieve high product yield and purity, low preparation cost, and reaction mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 0.002mol of sodium molybdate and 0.0045mol of thiourea and mix them in 50mL of ethylene glycol, fully stir and ultrasonically treat for 3 minutes, transfer the mixture to an autoclave, react at a constant temperature of 160°C for 24 hours, and then cool naturally. Wash twice with deionized water and absolute ethanol, and dry at 90 °C to obtain black MoS 2 Microspheres.

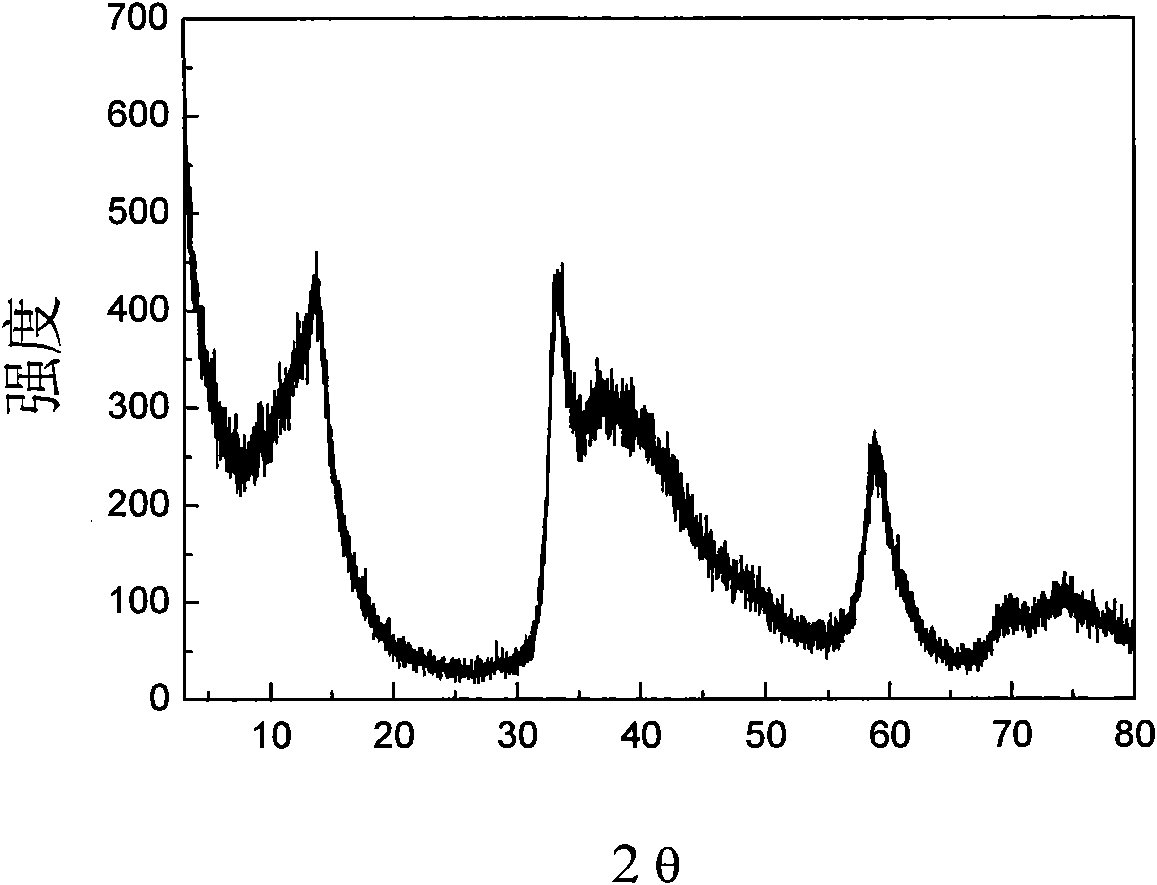

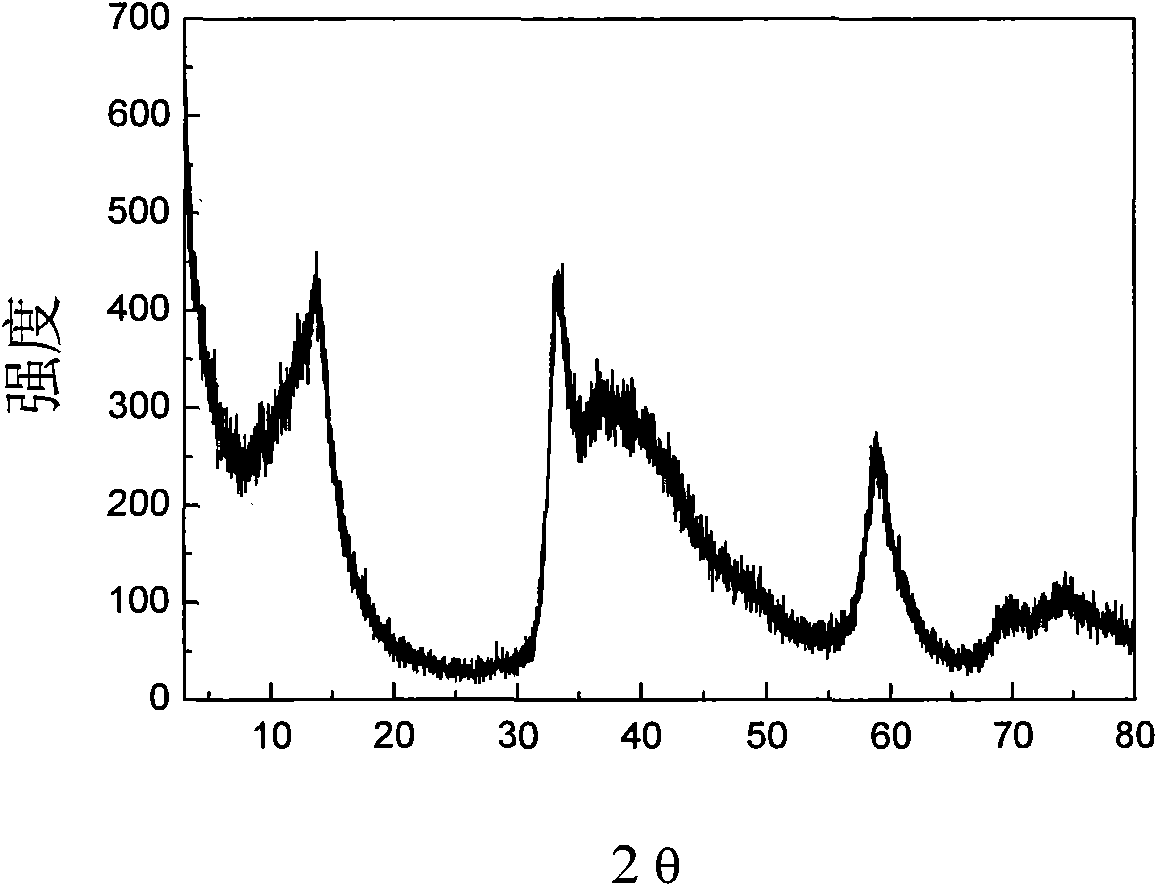

[0021] figure 1 is the resulting MoS 2 The XRD pattern of microspheres, compared with the standard card, it can be seen that the synthesized material is pure phase MoS 2 crystal material.

Embodiment 2

[0023] Weigh 0.005mol of ammonium paramolybdate and 0.07mol of thiourea and mix them in 60mL of glycerol, fully stir and ultrasonically treat for 5 minutes, transfer the mixture to an autoclave, react at a constant temperature of 180°C for 18 hours, and then cool naturally , washed three times with deionized water and absolute ethanol, and dried at 90 °C to obtain black MoS 2 Microspheres.

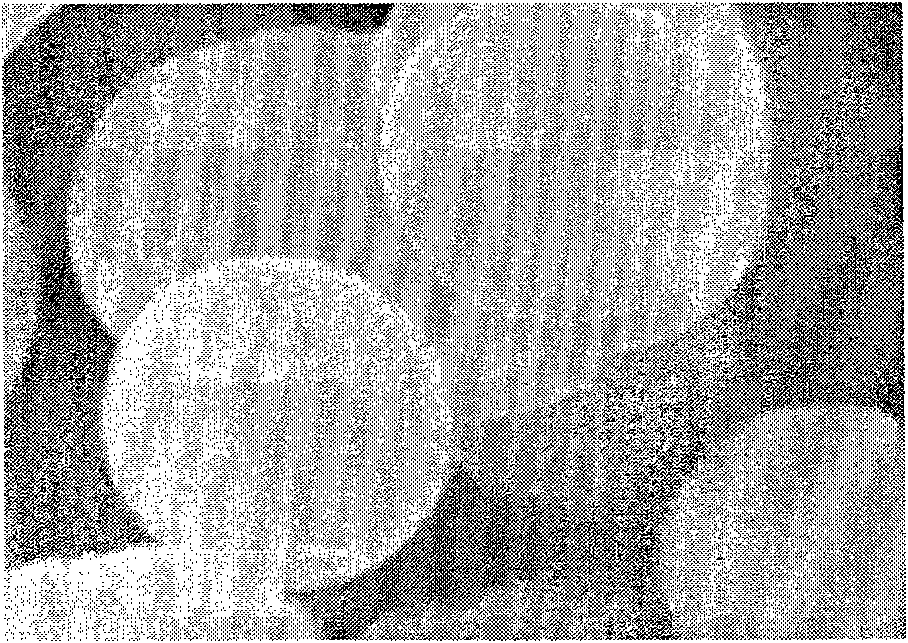

[0024] figure 2 is the resulting MoS 2 The SEM image of the microsphere, it can be seen from the figure that the obtained material is a uniform microsphere, and its particle size is about 1um.

Embodiment 3

[0026] Weigh 0.002mol of ammonium molybdate and 0.002mol of sodium thiosulfate and mix them in 70mL of n-propanol, fully stir and ultrasonically treat for 5 minutes, transfer the mixture to an autoclave, and react at a constant temperature of 190°C for 12 hours, then naturally Cool, wash twice with deionized water and absolute ethanol, and dry at 90°C to obtain black MoS 2 Microspheres. The detection of SEM images shows that the obtained MoS 2 The material is uniform microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com