Application of graphite conductive adhesive to prepare electrode-detection binder

A conductive adhesive and graphite technology, applied in the direction of conductive adhesives, adhesives, adhesive types, etc., can solve the problems of decreased electrode conductivity, increased electrode internal resistance and polarization, and slow electrode activation, achieving excellent The effect of conductivity and adhesion, simple and easy preparation method, and controllable electrode area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1.7 grams of E-12 epoxy resin (E-44 epoxy resin), 1.0 grams of graphite powder (natural graphite), 0.60 grams of 1,4-butanediol diglycidyl ether, 0.07 grams of polyethylene polyamine, as follows Steps to deploy:

[0031] Take 1.0 g of graphite powder, put it in 0.50M KOH and treat it at 100°C for 30 minutes, cool, filter, wash with distilled water until neutral; then use 0.50MHNO 3 Repeat the treatment according to the same steps; finally, vacuum-dry at 120°C to clean and activate the graphite for later use.

[0032] The graphite powder of the above-mentioned treatment, 0.60 grams of 1,4-butanediol diglycidyl ether, after fully mixing and grinding in a mortar, then add 1.7 grams of E-12 epoxy resin, mix and grind evenly, then add polyethylene polyvinyl ether dropwise 0.07 g of amine was mixed and ground to obtain graphite conductive adhesive.

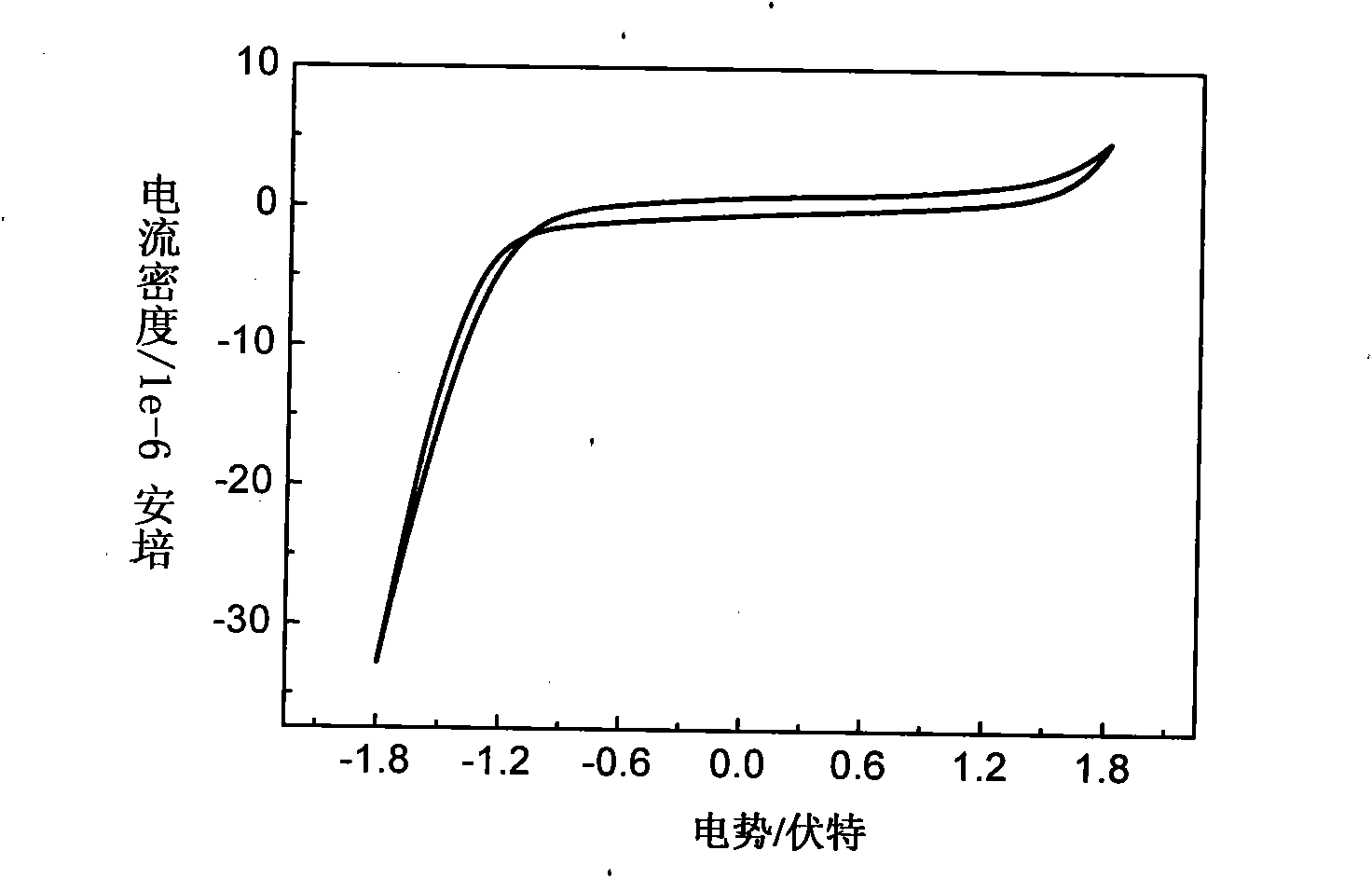

[0033] Roll the graphite conductive adhesive into a film, cut it into a film of the required size, and bond it to the substra...

Embodiment 2

[0035] 1.7 grams of E-12 epoxy resin (JF-220 epoxy resin), 1.3 grams of graphite powder (artificial graphite), 0.35 grams of terpineol, 0.07 grams of trimethylhexamethylenediamine, and prepare according to the following steps :

[0036] Take 1.3 grams of graphite powder, put it into 0.50M KOH and treat it at 100°C for 30 minutes, cool, filter, wash with distilled water until neutral; then use 0.50MHNO 3 Repeat the treatment according to the same steps; finally, vacuum-dry at 120°C to clean and activate the graphite for later use.

[0037] The graphite powder of the above-mentioned treatment, 0.35 grams of terpineol, after fully mixing and grinding in a mortar, then add 1.7 grams of E-12 epoxy resin, mix and grind evenly, then add 0.07 grams of trimethylhexamethylenediamine dropwise , mixed and ground to obtain graphite conductive adhesive.

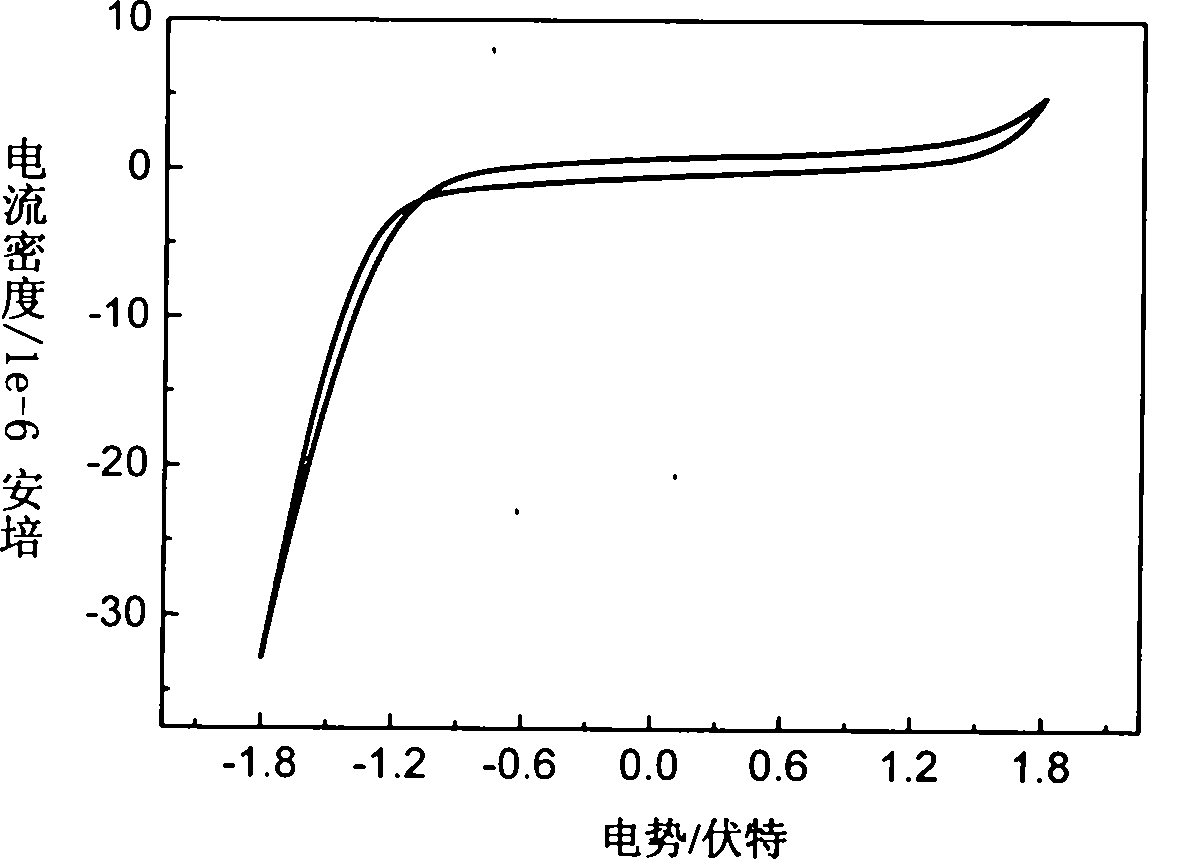

[0038] Roll the graphite conductive adhesive into a film, cut it into a film of the required size, and bond it to the substrate glassy ...

Embodiment 3

[0040] E-12 epoxy resin (E-12 and JF-220 epoxy resin weight mix) 0.50 grams, graphite powder (natural graphite and artificial graphite equal weight mix) 0.30 grams, ethylene glycol butyl ether acetate 0.17 grams, diamine Base diphenyl sulfone 0.03 gram, allocate according to the following steps:

[0041] Take 0.30 g of graphite powder, put it into 0.50M KOH and treat it at 100°C for 30 minutes, cool, filter, wash with distilled water until neutral; then use 0.50MHNO3 Repeat the treatment according to the same steps; finally, vacuum-dry at 120°C to clean and activate the graphite for later use.

[0042] The graphite powder of above-mentioned processing, ethylene glycol butyl ether acetate 0.17 gram, after fully mixing and grinding in mortar and mortar, add E-12 epoxy resin 0.50 gram again, mixing and grinding is even, then drips diamino diphenyl sulfone ( DDS) 0.03 g, mixed and ground to obtain graphite conductive adhesive.

[0043] Roll the graphite conductive adhesive into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com