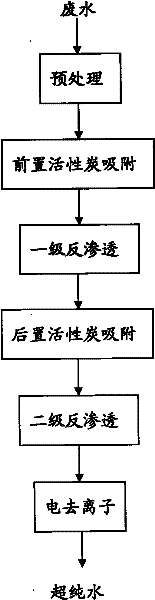

Treatment technique for recycling waste water into industrial ultrapure water

A treatment process and ultra-pure water technology, applied in the direction of adsorption water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. problem, achieve the effect of increasing the cost of use and preventing organic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

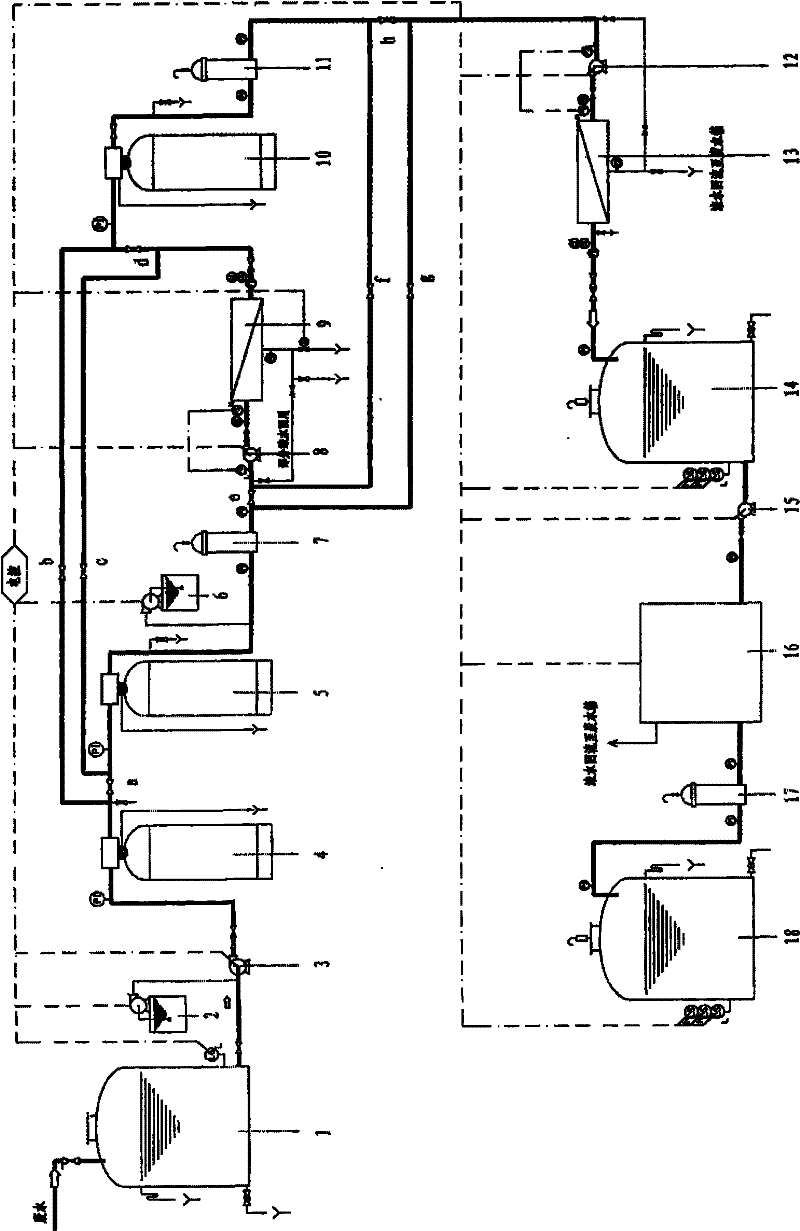

[0018] Such as figure 2 Shown is a treatment system for industrial ultrapure water reused according to the process of the present invention, including a waste water tank 1, a dosing device 2, a raw water pump 3, a multimedia filter 4, and a pre-activated carbon filter 5 , antiscalant adding device 6, first security filter 7, primary high pressure pump 8, primary reverse osmosis treatment device 9, rear activated carbon filter 10, second security filter 11, secondary high pressure pump 12, secondary Stage reverse osmosis treatment device 13, pure water tank 14, pure water pump 15, electrodeionization device 16, terminal filter 17, ultrapure water tank 18, the above-mentioned equipment is connected in sequence.

[0019] The outlet of the dosing device 2 is connected between the waste water tank 1 and the raw water pump 3 , and the outlet of the antiscalant adding device 6 is connected between the pre-activated carbon filter 5 and the first security filter 7 .

[0020] A valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com