Resin composition

A technology of resin composition and compound, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of no hard coating record, no consideration of shrinkage rate, no requirement of hardness and scratch resistance, etc., to achieve shrinkage The effect of low rate and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

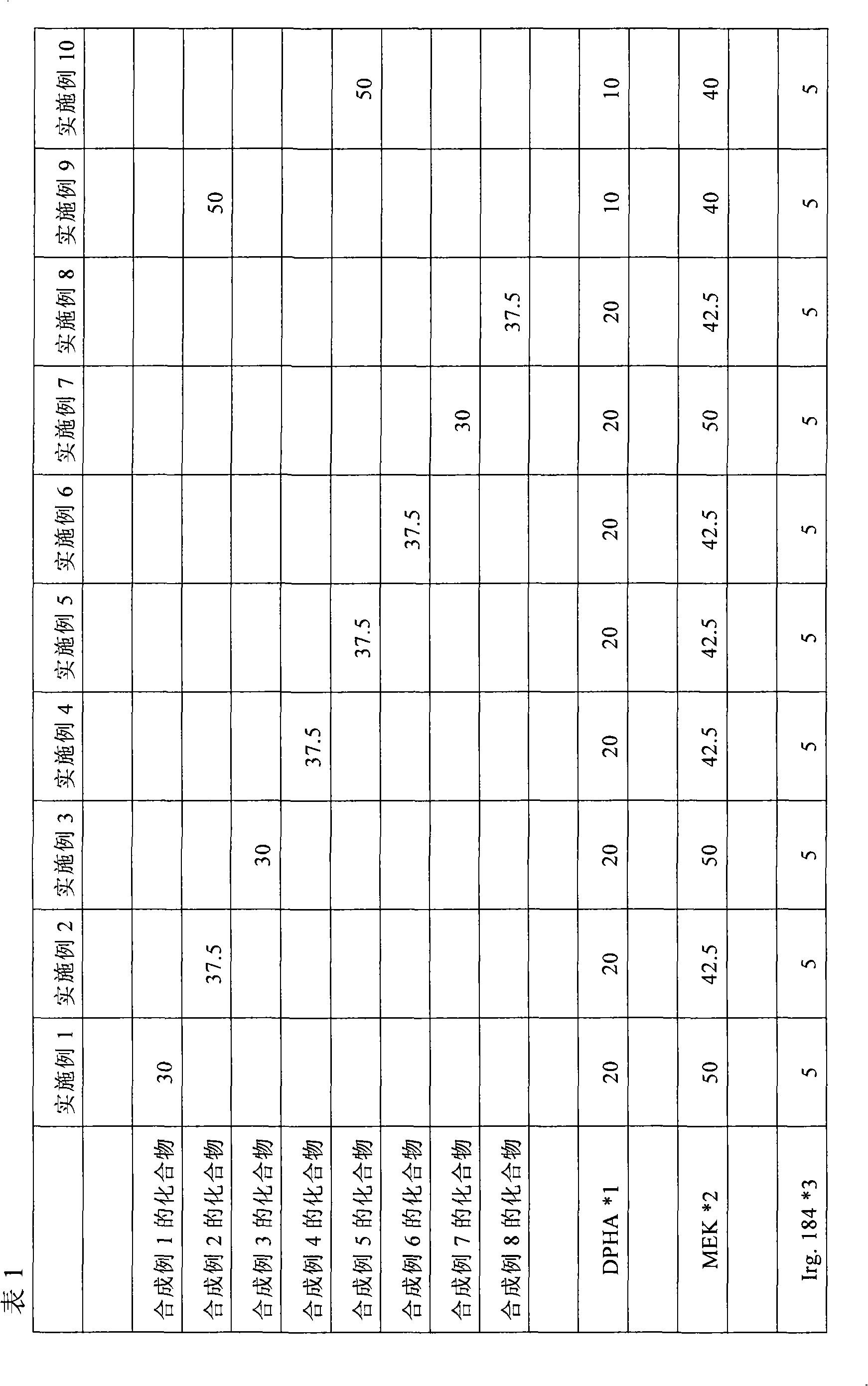

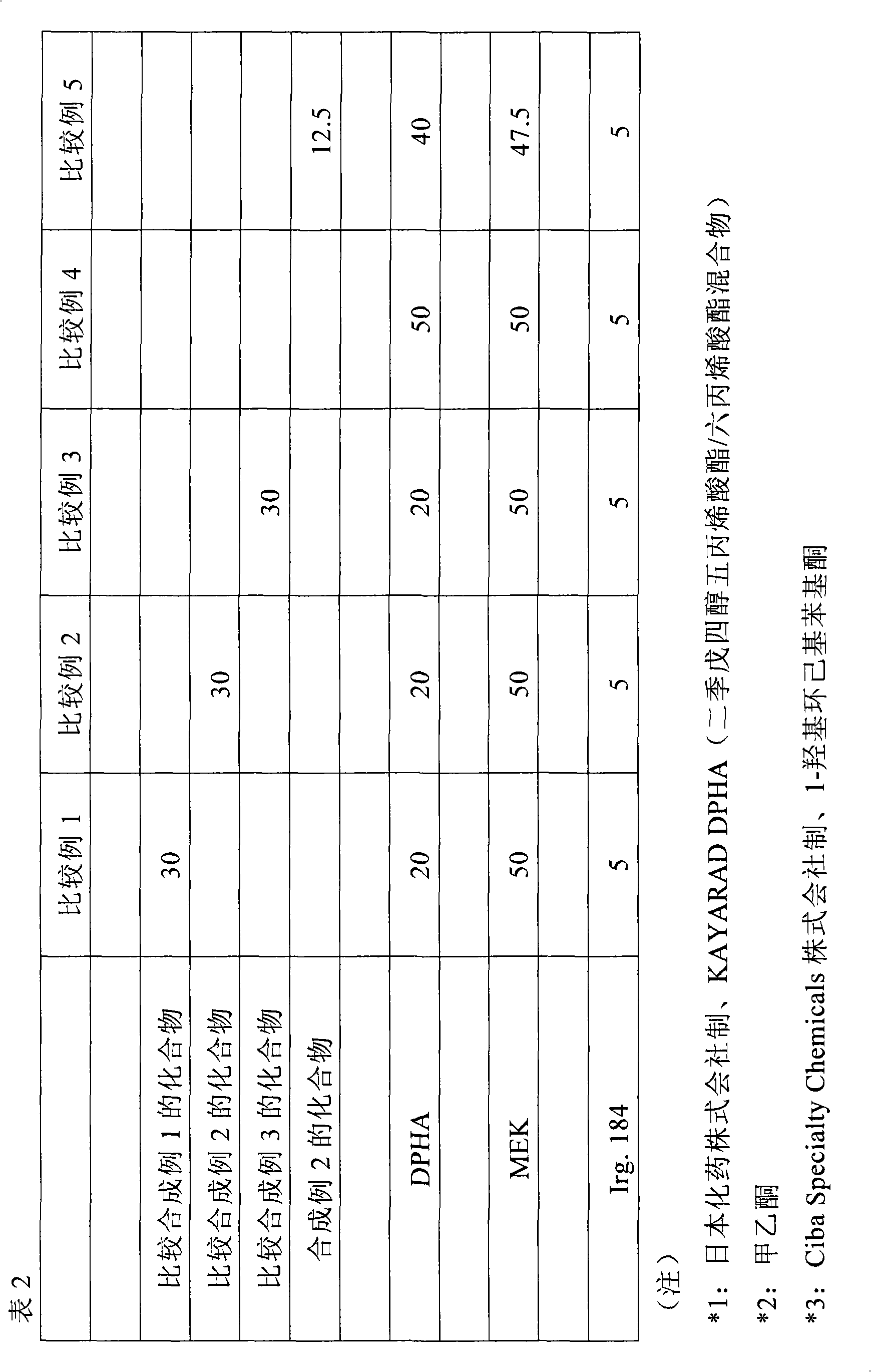

Examples

Embodiment

[0060] Hereinafter, the present invention will be described in more detail through examples, but the present invention is not limited to these examples. In addition, in an Example, unless otherwise specified, "part" means "part by mass".

Synthetic example 1

[0062] Add 344.35 g (1.54 moles) of glycerol monoacrylate monomethacrylate, 0.25 g of 4-methoxyphenol as a polymerization inhibitor, and 0.25 g of 4-methoxyphenol as an amino 0.25 g of dibutyltin dilaurate as a formate reaction catalyst was stirred uniformly so that the internal temperature was 50°C. Then, 155.65 g (0.70 mol) of isophorone diisocyanate was added dropwise so that the internal temperature did not exceed 80°C, and after the addition, it was reacted at 80°C, and the time when the NCO content became 0.1% or less was regarded as the end point of the reaction to obtain a carbamate Acrylate.

Synthetic example 2

[0064] Add 262.60 g (1.17 moles) of glycerol monoacrylate monomethacrylate, 125.00 g of methyl ethyl ketone, and 0.25 g of 4-methoxyphenol as a polymerization inhibitor in a reactor equipped with a reflux condenser, a stirrer, a thermometer and a temperature regulating device. g. Stir 0.25 g of dibutyltin dilaurate as a urethanization reaction catalyst to make the internal temperature 50°C. Then, 237.40 g (0.36 mol) of T-1890 (isophorone diisocyanate trimer) was added dropwise so that the internal temperature did not exceed 80°C, and after the addition, it was reacted at 80°C, and the time when the NCO content reached 0.1% or less was regarded as At the end of the reaction, a resin solution containing 80% of urethane acrylate was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com