Supermolecular organic solar cell and preparation method thereof

A solar cell and supramolecular technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low photoelectric conversion efficiency, inability to spontaneously dissociate, and low carrier mobility in organic solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

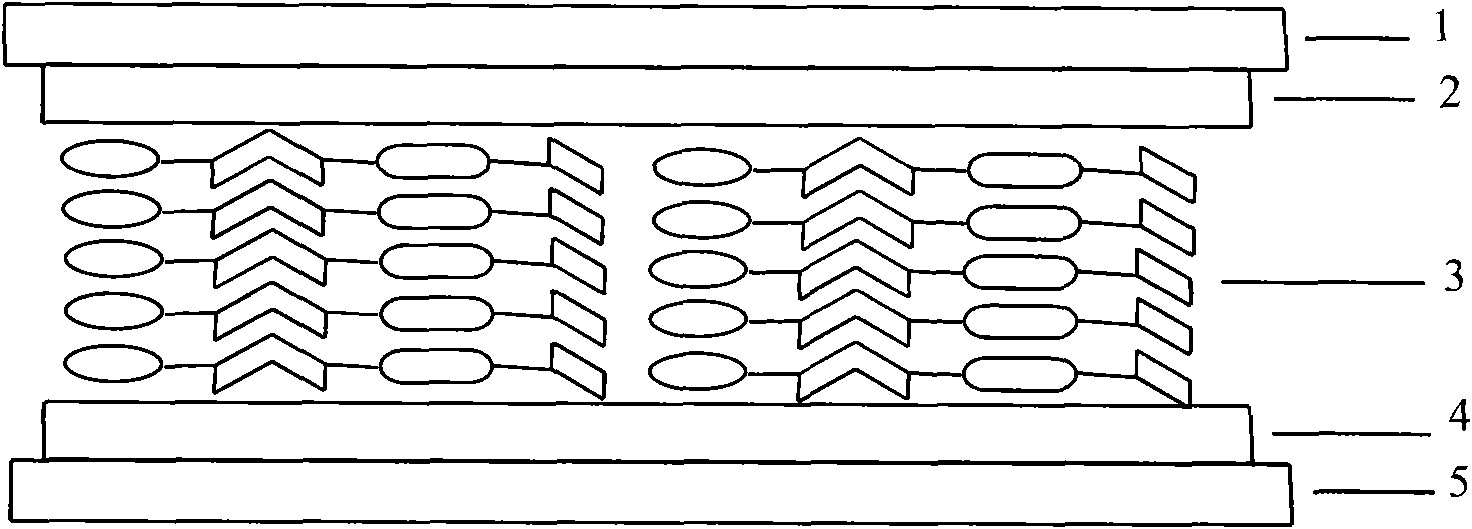

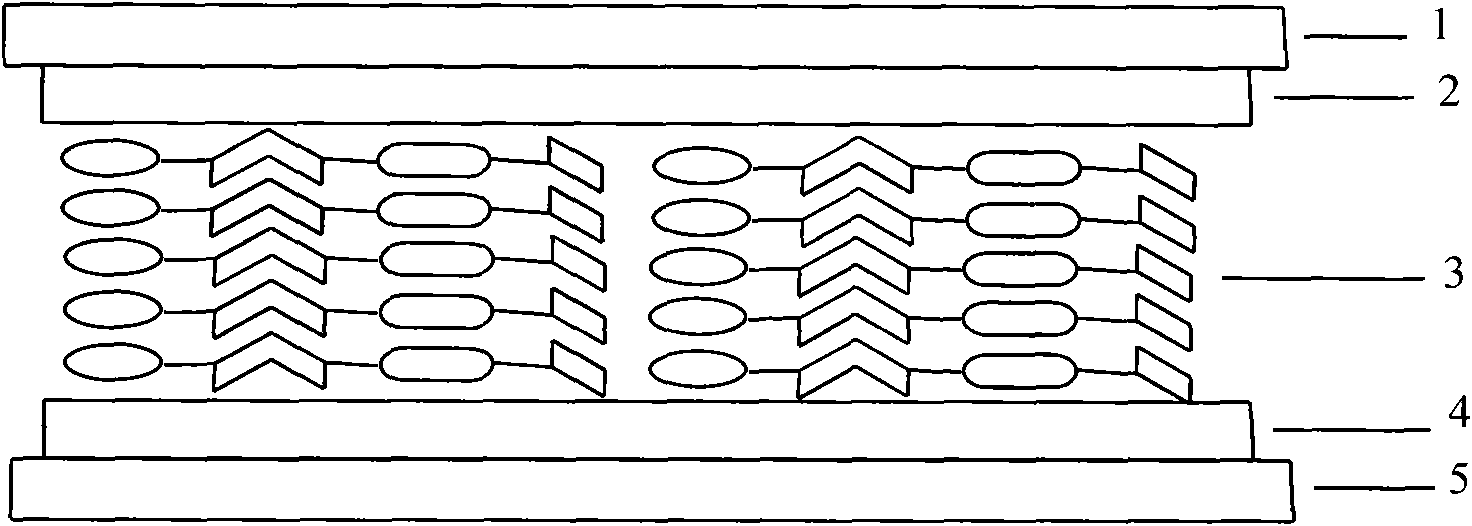

[0037] The present invention also proposes a preparation method of a supramolecular organic solar cell, the preparation method comprising the following steps:

[0038]1) Covering the electrode material with a hole transport material to form a thin film on the surface of the metal anode by vacuum evaporation or sputtering or other similar methods to obtain an anode layer;

[0039] 2) Coating the supramolecular power generation layer material containing the donor acceptor block on the hole transport layer by spin coating, and then performing annealing and other treatments to form the power generation layer. The power generation layer can also be prepared by covering the hole transport layer with the power generation layer material by self-assembly method or vapor phase growth method;

[0040] 3) forming an electron transport layer on the power generation layer by spin coating or vapor phase growth;

[0041] 4) Evaporating the cathode on the electron transport layer; spin coatin...

Embodiment 1

[0053] An ITO anode electrode with a thickness of 150-200nm is formed on the cleaned ITO glass substrate. Then ultrasonic cleaning in acetone, isopropanol and ultrapure water for 10 min followed by UV / ozone treatment. Then rinse and dry in the vapor phase of isopropanol. The substrate surface was treated for 3 minutes by the air pressure plasma surface treatment device.

[0054] Next, polyethylenedioxythiophene:polystyrenesulfonate (salt) (manufactured by Starck Ltd.) was formed to a thickness of 50 nm on the ITO film anode layer as a hole transport layer.

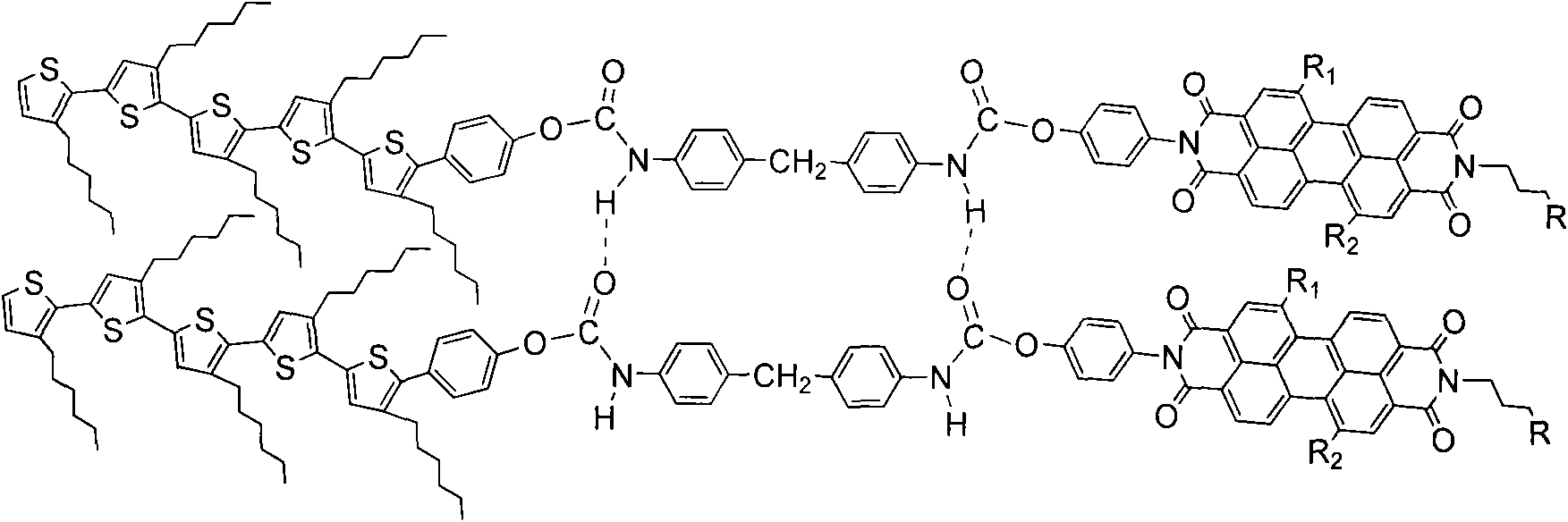

[0055] The target power generation layer molecular material (block molecule of thiophene benzamide ester perylene, molecular structure see figure 2 , and its preparation method refers to patent 200910183855.1) Spin coating on the hole transport layer to form a power generation layer with a thickness of about 100nm. Dry under vacuum at room temperature. Then microwave heating to 60 ℃ annealing 2-3 minutes. A supramole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com