Floating type Fe-TiO2/cenosphere photocatalyst and preparation method and application thereof

A technology of fe-tio2 and catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. It can solve the problems of resource waste and difficult recycling, and achieve easy recycling , easy to accept light, easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

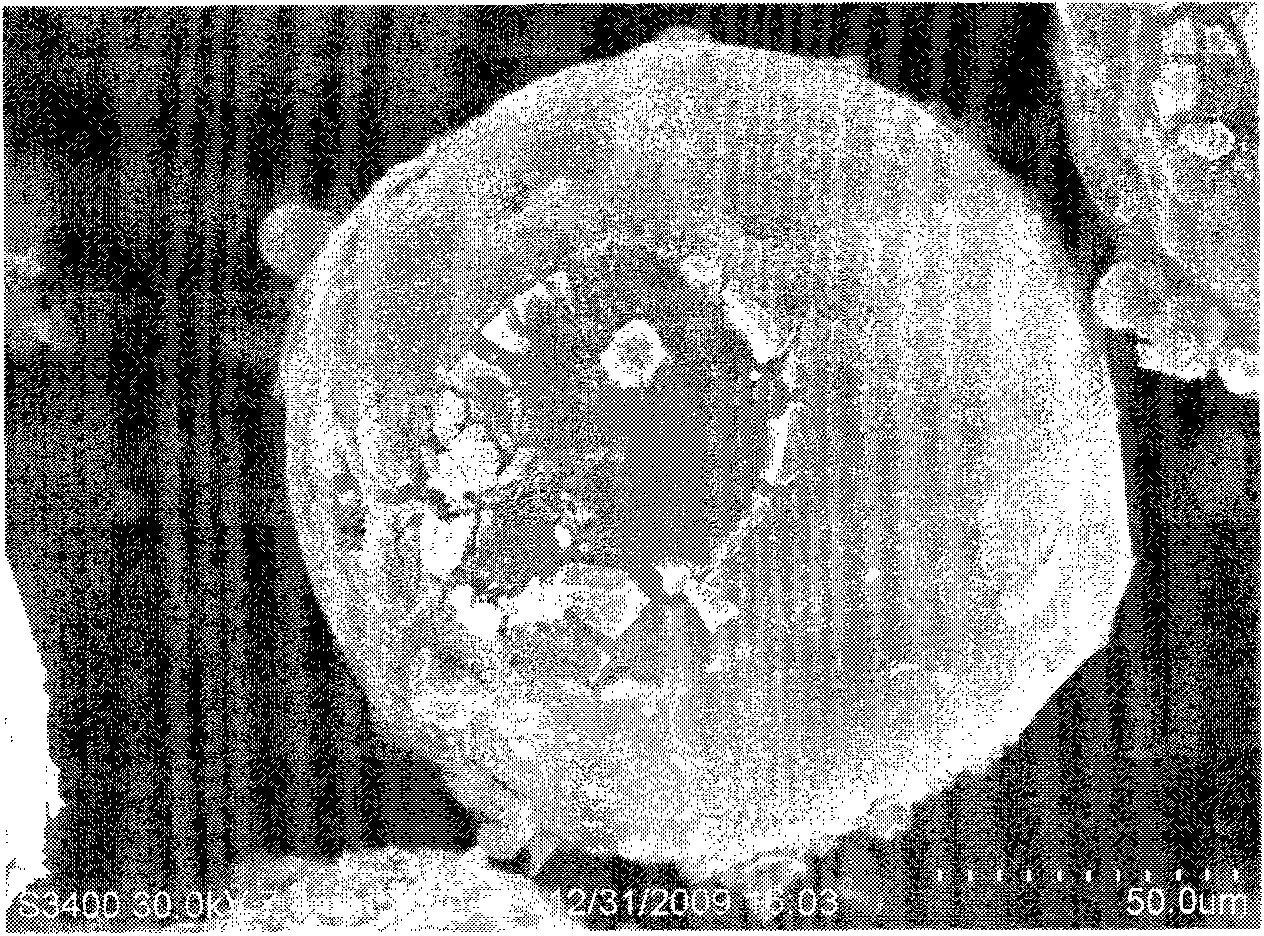

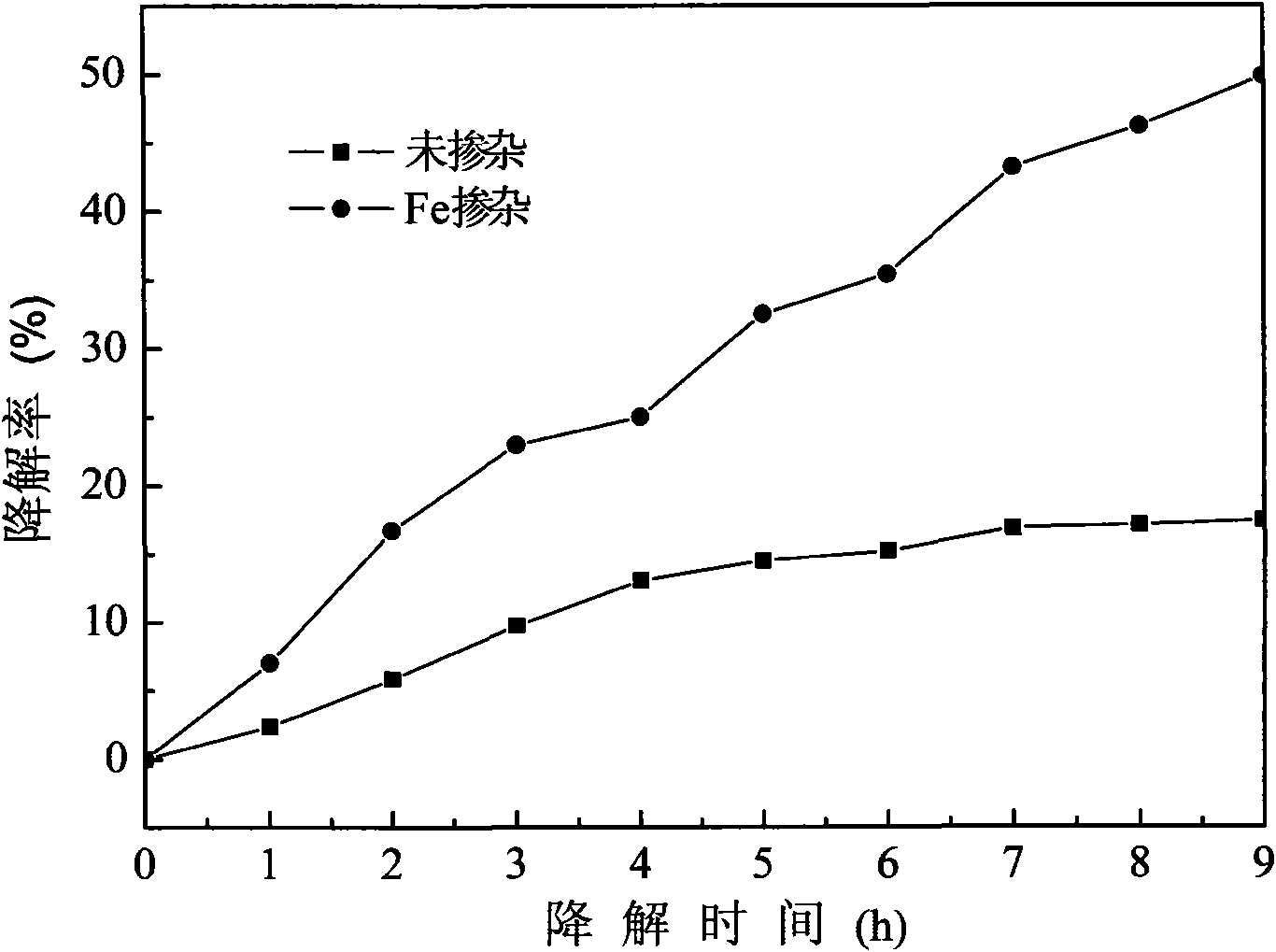

[0021] 1) Fly ash bleaching beads pretreatment: Soak with 10% by weight dilute nitric acid for 8 hours, rinse with a large amount of distilled water until the outflowing water is neutral, dry and set aside.

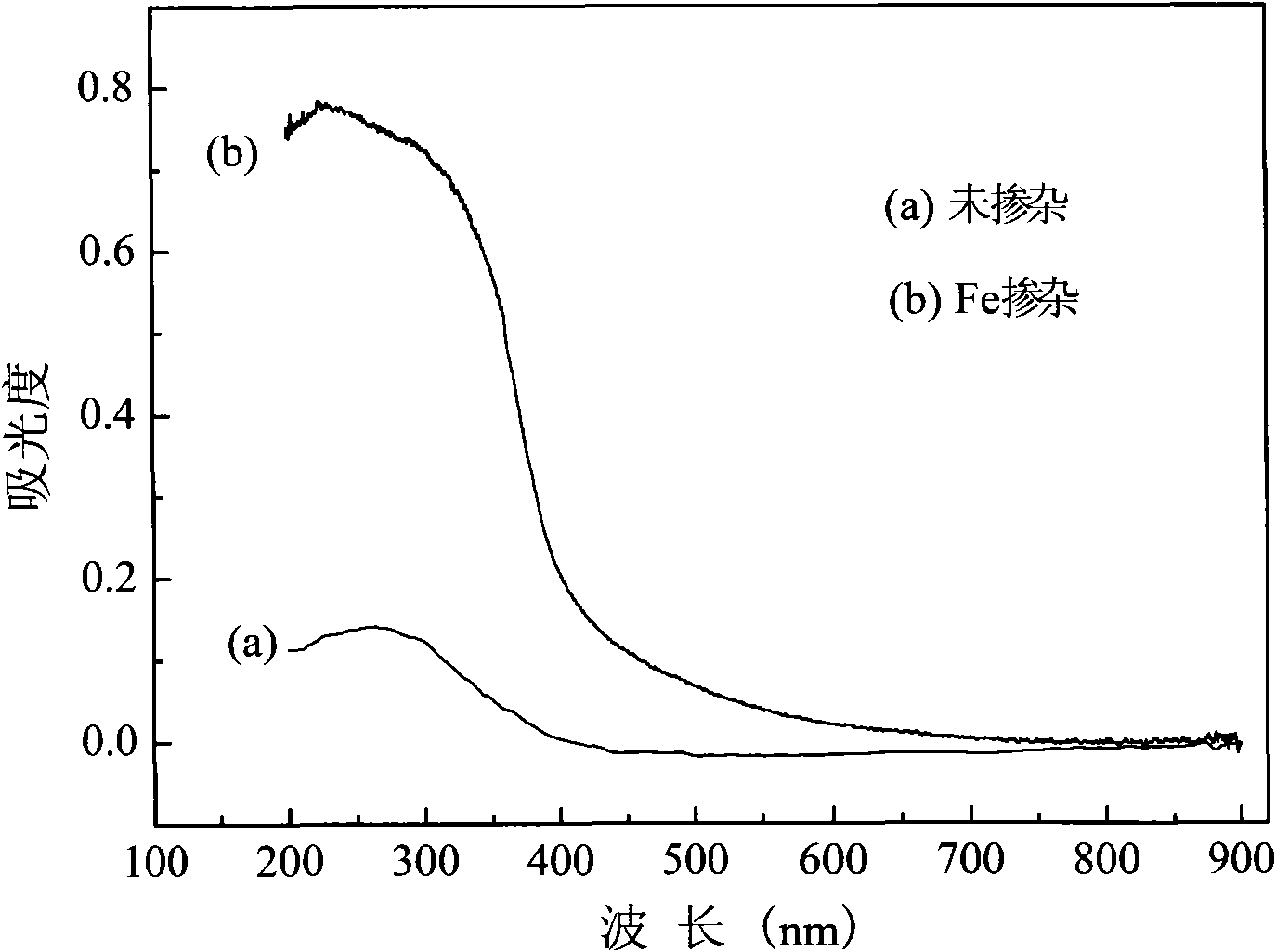

[0022] 2) With 34g butyl titanate, 71g absolute ethanol, 9.8g acetylacetone, 0.004g Fe(NO 3 ) 3 Take 1.8g of ultrapure water as raw material, adjust its pH to 5 with concentrated nitric acid, stir for 1 hour to make it fully react, then add 2.5g of polyethylene glycol 20000, heat and stir to fully dissolve it, and obtain yellow transparent doped Impurity Fe 3+ Element TiO 2 Sol;

[0023] 3) to the doped Fe prepared in step 2) 3+ Element TiO 2 Add 3.4g of pretreated floating bead carrier to the sol, stir to make it evenly mixed, impregnate for 12h, filter off the excess sol, dry the filtered sample, and then place it in a muffle furnace for calcination at 550°C for 2.5h , cooled to room temperature in air after calcination;

[0024] 4) Secondary loading process: Usi...

Embodiment 2

[0032] 1) Pretreatment of fly ash floating beads: Soak with 10% by weight dilute nitric acid for 10 hours, rinse with a large amount of distilled water until the outflowing water is neutral, and dry it for later use.

[0033] 2) With 34g butyl titanate, 71g absolute ethanol, 9.8g acetylacetone, 0.002g Fe(NO3 ) 3 Take 1.8g of ultrapure water as raw material, adjust its pH to 3.5 with concentrated nitric acid, stir for 1 hour to make it fully react, then add 2g of polyethylene glycol 20000, heat and stir to fully dissolve it, and obtain yellow transparent doped Fe 3+ Element TiO 2 Sol;

[0034] 3) to the Fe-TiO obtained in step 2) 2 Add 5g of pretreated floating bead carrier to the sol, stir to make it evenly mixed, impregnate for 24 hours, filter off the excess sol, dry the filtered sample, and then place it in a muffle furnace for calcination at 450°C for 2 hours, then calcined After cooling to room temperature in air;

[0035] 4) Secondary loading process: Using the samp...

Embodiment 3

[0040] 1) Fly ash bleaching beads pretreatment: Soak in 10% dilute nitric acid for 12 hours, rinse with a large amount of distilled water until the outflowing water is neutral, dry and set aside.

[0041] 2) With 34g butyl titanate, 71g absolute ethanol, 9.8g acetylacetone, 0.02g Fe(NO 3 ) 3 And 1.8g of ultrapure water as raw material, adjust its pH to 5.5 with concentrated nitric acid, stir for 1 hour to make it fully react, then add 1.7g of polyethylene glycol 20000, heat and stir to fully dissolve it, and obtain yellow transparent doped Impurity Fe 3+ Element TiO 2 Sol;

[0042] 3) to the Fe-TiO obtained in step 2) 2 Add 6.8g of pretreated floating bead carrier to the sol, stir to make it evenly mixed, impregnate for 36h, filter off the excess sol, dry the filtered sample, and then place it in a muffle furnace for calcination at 600°C for 1.5h , cooled to room temperature in air after calcination;

[0043] 4) Secondary loading process: Using the sample obtained in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com