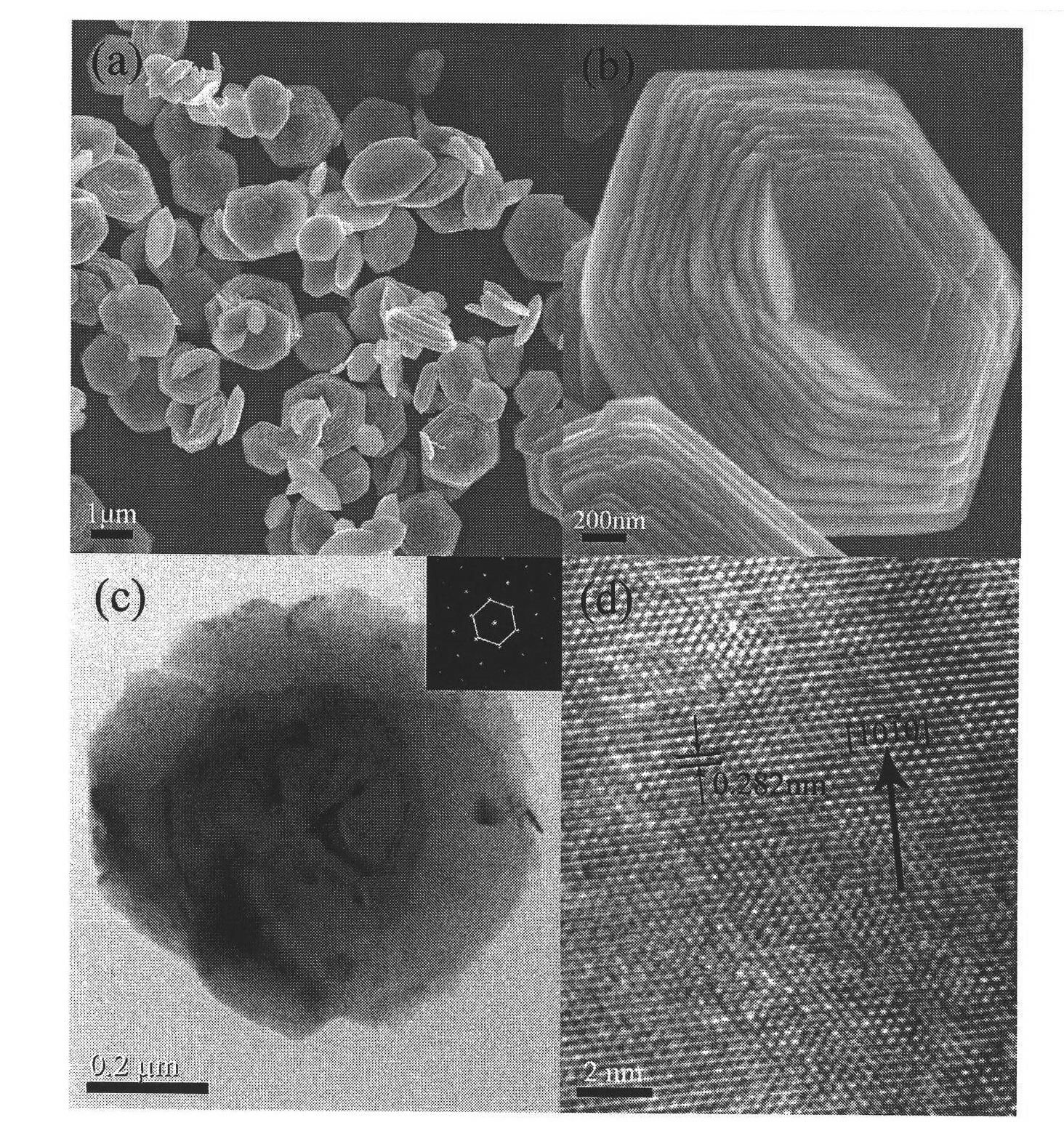

Method for preparing zinc oxide in three-dimensional nanostructure with cryogenic fluid method

A low-temperature solution method and three-dimensional nanotechnology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of inability to observe the growth process, high technical difficulty, high equipment requirements, etc., and achieve accelerated relative growth speed and mild process conditions , The effect of simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

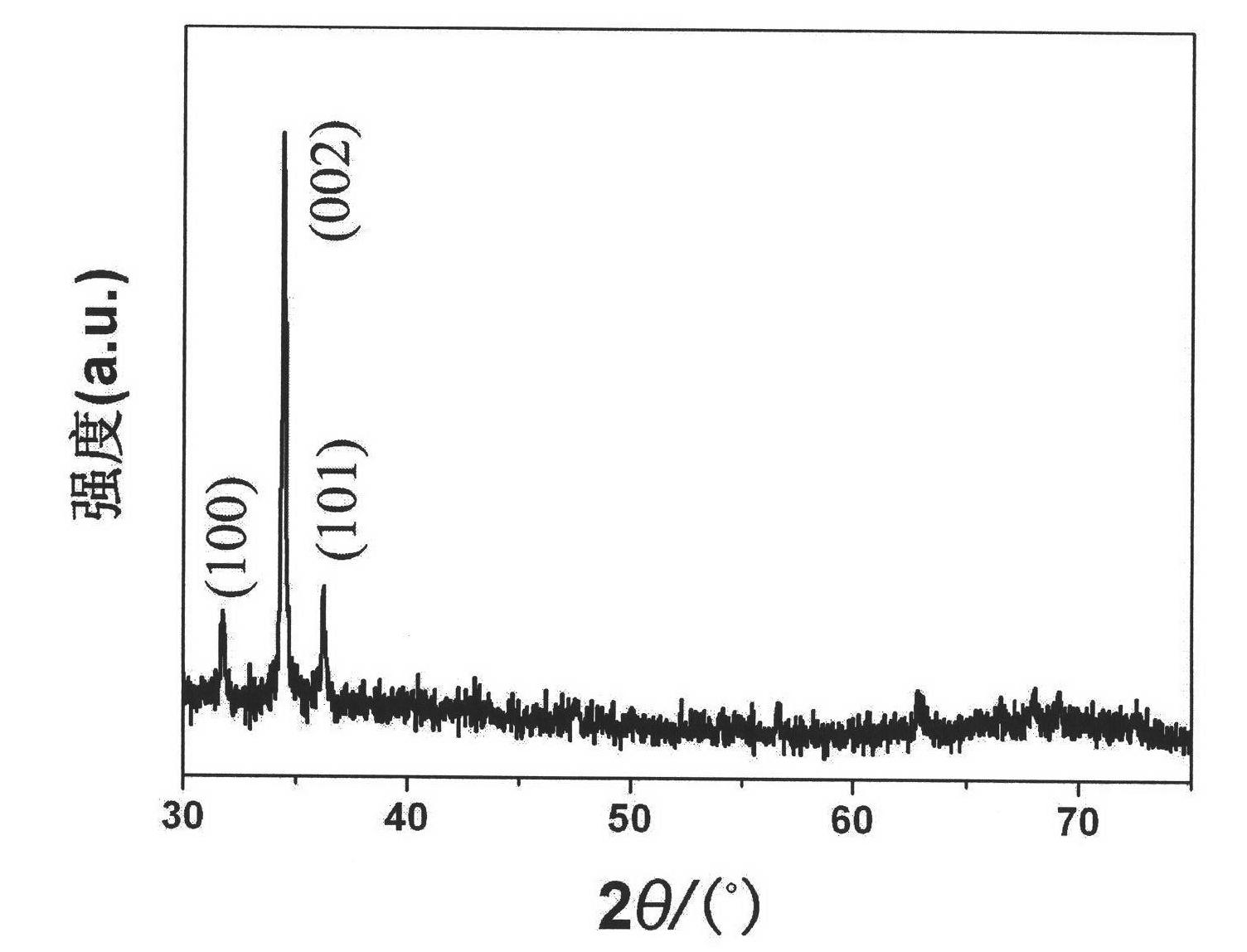

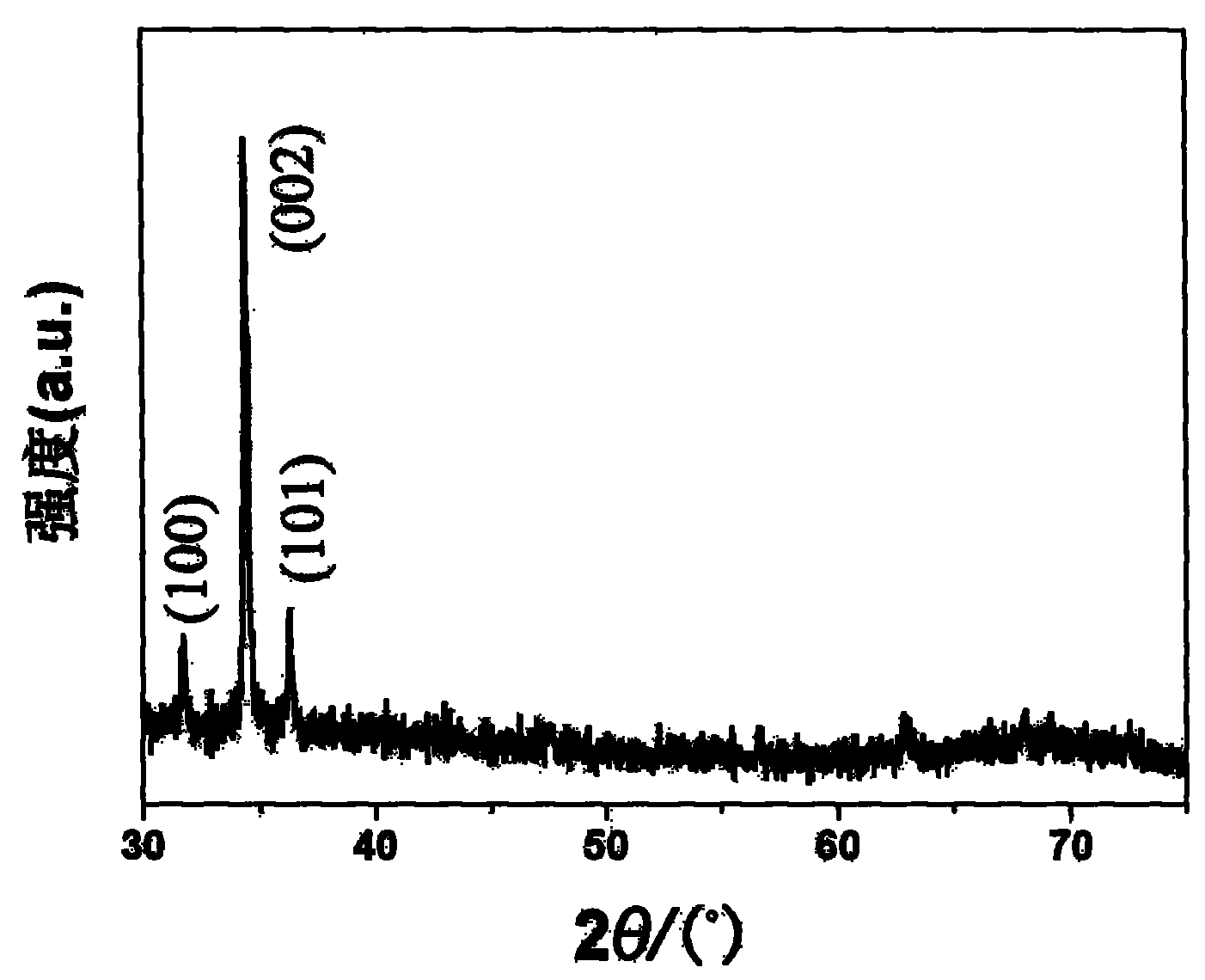

[0024] Example 1: Preparation of three-dimensional nanostructured zinc oxide:

[0025] (1). The single-sided polished silicon chip is put into ethanol and acetone solutions and ultrasonicated for half an hour to remove the organic matter on the surface of the silicon chip; then put into hydrogen peroxide (30%), ammonia water (30%), deionized water (volume ratio 1:1:5) mixed solution, do hydrophilic treatment at 85°C for 1 hour;

[0026] (2). Weigh a certain amount of 0.1098g Zn(AC) 2 2H 2 O was put into ethanol (25ml) solution, placed on a magnetic stirrer and stirred to fully dissolve. Then spin-coat the zinc acetate ethanol solution (speed: 1000 rpm) on the polished surface of the silicon wafer (5-7 times), and dry it in a blast drying oven at 100°C for 1 hour;

[0027] (3). 1.8593g Zn(NO 3 ) 2 ·6H 2 O and 0.8762g hexamethylenetetramine into 250ml deionized water, then add 1.16g EDTA-2Na·2H 2 O magnetic stirring to dissolve;

[0028] (4). Hang the dried silicon chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com