Process for purifying and recycling biomass organic wastewater

A technology of organic wastewater and biomass, which is applied in the treatment and recycling of organic wastewater, wastewater treatment and recycling, can solve the problems of increased management difficulty, increased power, increased preparation, and increased consumption, and achieves easy operation control and odor control , less nutrients required for anaerobic, easy construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

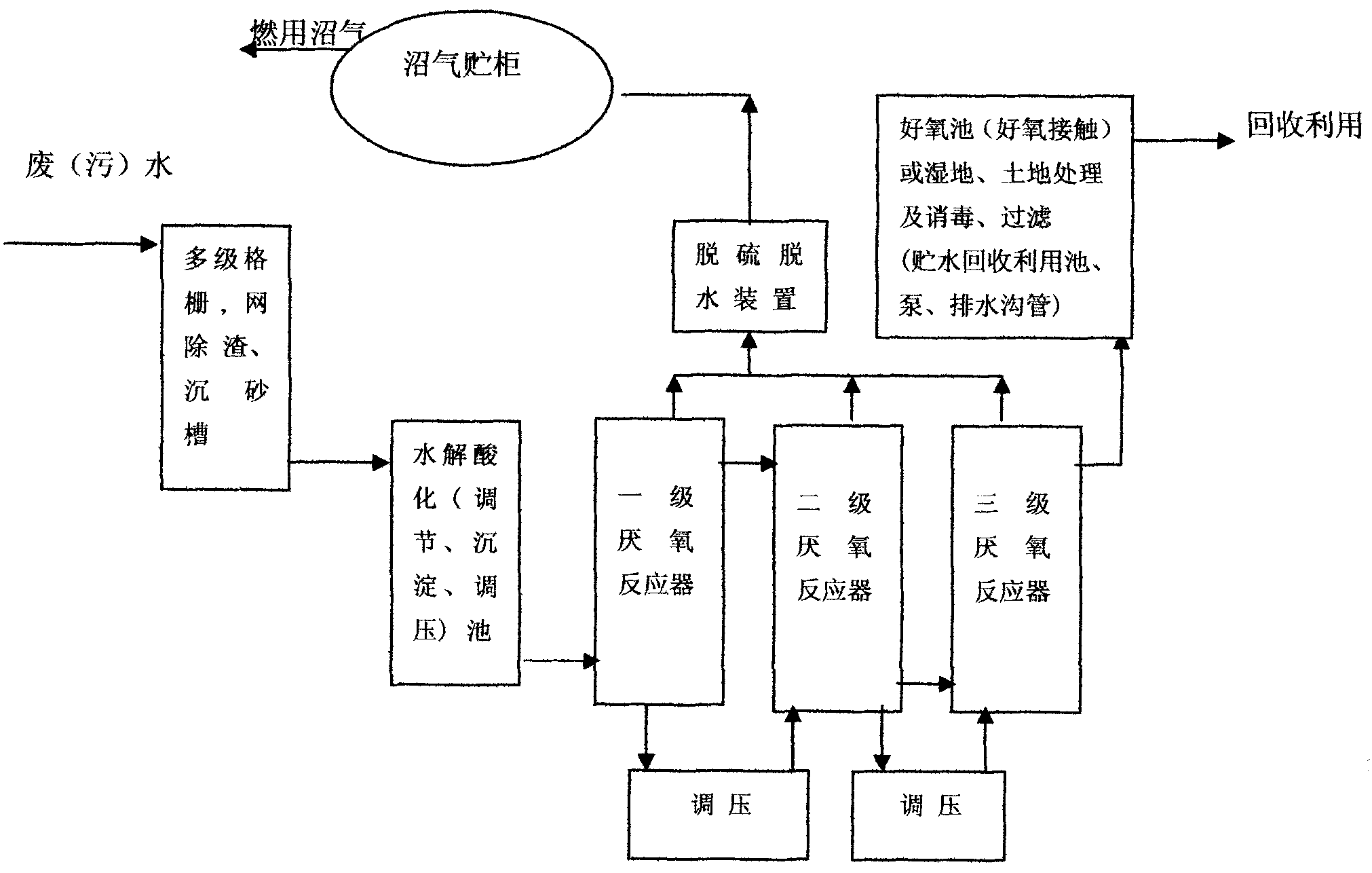

Method used

Image

Examples

Embodiment 1

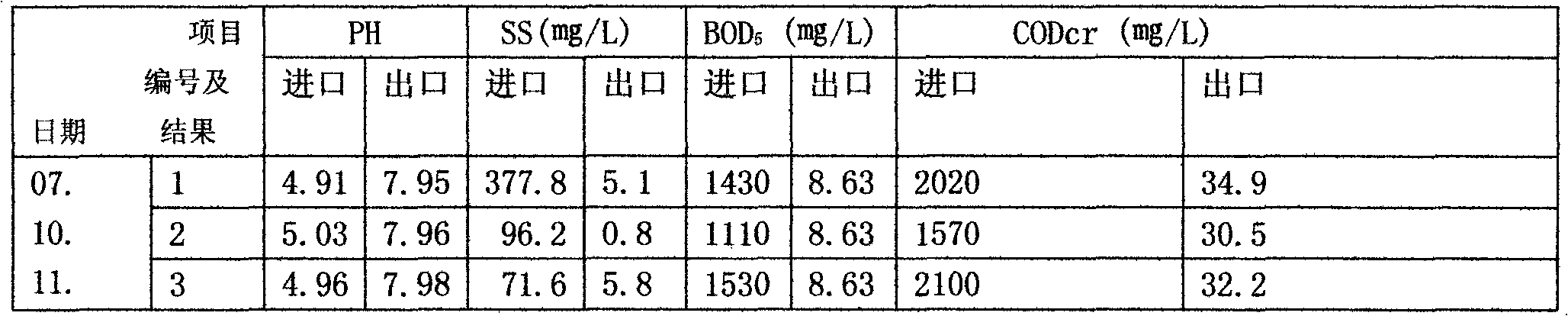

[0071] Process flow of the present invention treats 10m of soybean milk factory production wastewater 3 / d, sampling and monitoring before and after treatment, the monitoring data are as follows:

[0072] sampling date

Embodiment 2

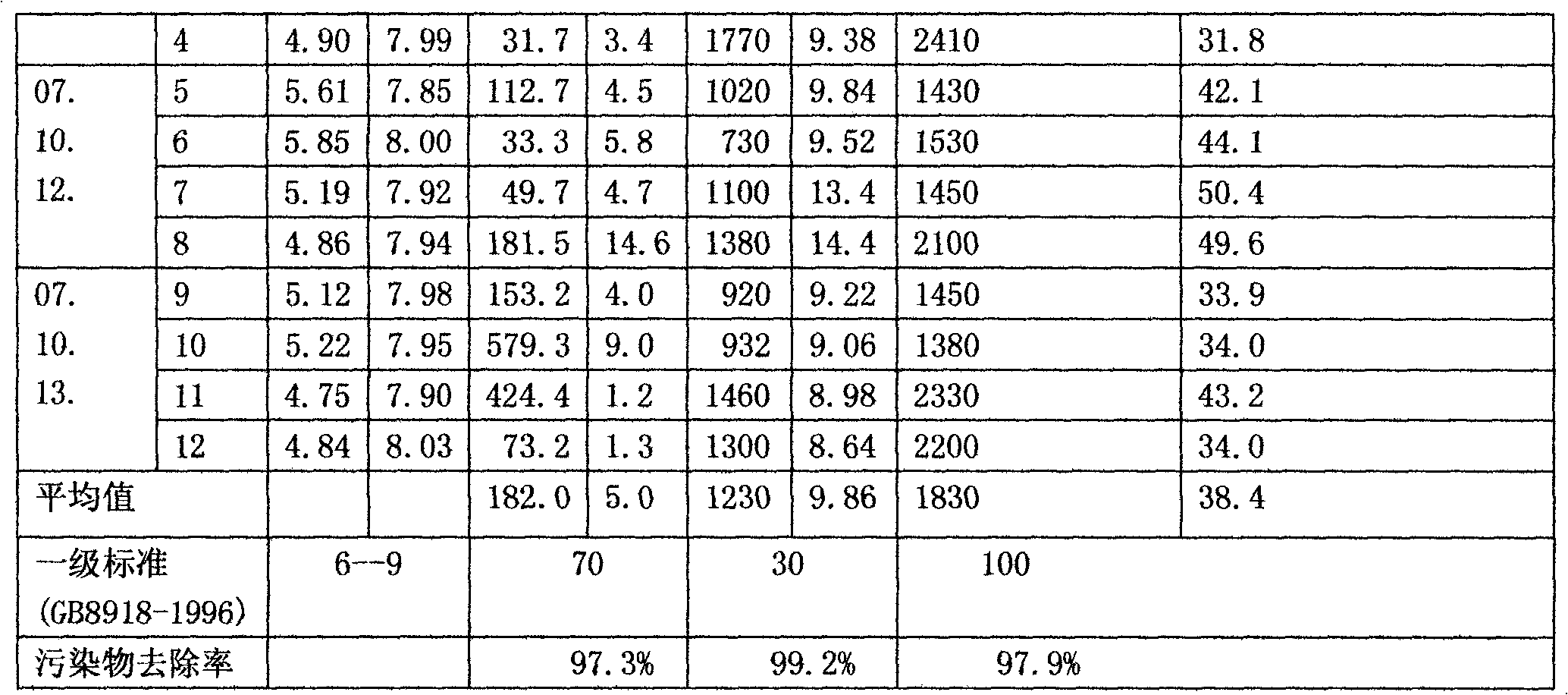

[0074] The technical process of the present invention treats 120m of winery wastewater 3 / d (including domestic sewage 20m 3 / d), which handles import and export acceptance sampling monitoring, and the monitoring results are as follows:

[0075]

[0076]

Embodiment 3

[0078] Process flow of the present invention treats dairy farm wastewater 100m 3 / d, the acceptance monitoring results are as follows:

[0079]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com