Radiation-resistant concrete based on environment protection type functional aggregates and preparation method thereof

An environmentally friendly, radiation-proof technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as inability to adapt to design requirements, impossible to meet engineering construction, and prevention of poor neutron rays, etc. Achieve the effects of low ion dissolution rate, low cost, excellent crack resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of environment-friendly functional aggregate:

[0034] Take 100 parts (mass) of a lake silt in a city as the main material, add 2 parts (mass) of BaO as an auxiliary material, and then add 1 part (mass) of Na 3 PO 4 Use as a flux, mix evenly, and carry out step-by-step calcination in a high-temperature furnace. The step-by-step calcination system is: heating and holding at 105°C for 30 minutes, heating and holding at 450°C for 45 minutes, heating and holding at 850°C for 30 minutes, and heating and holding at 1100°C for 2 hours. The heating rate of each stage shall not be higher than 10°C / min. After the calcination is completed, it is cooled with the furnace to obtain an environmentally friendly functional aggregate. Determination of its TCLP value is shown in Table 4, and its physical performance index is shown in Table 5.

Embodiment 2~4

[0035] Examples 2-4: Preparation of environment-friendly functional aggregates

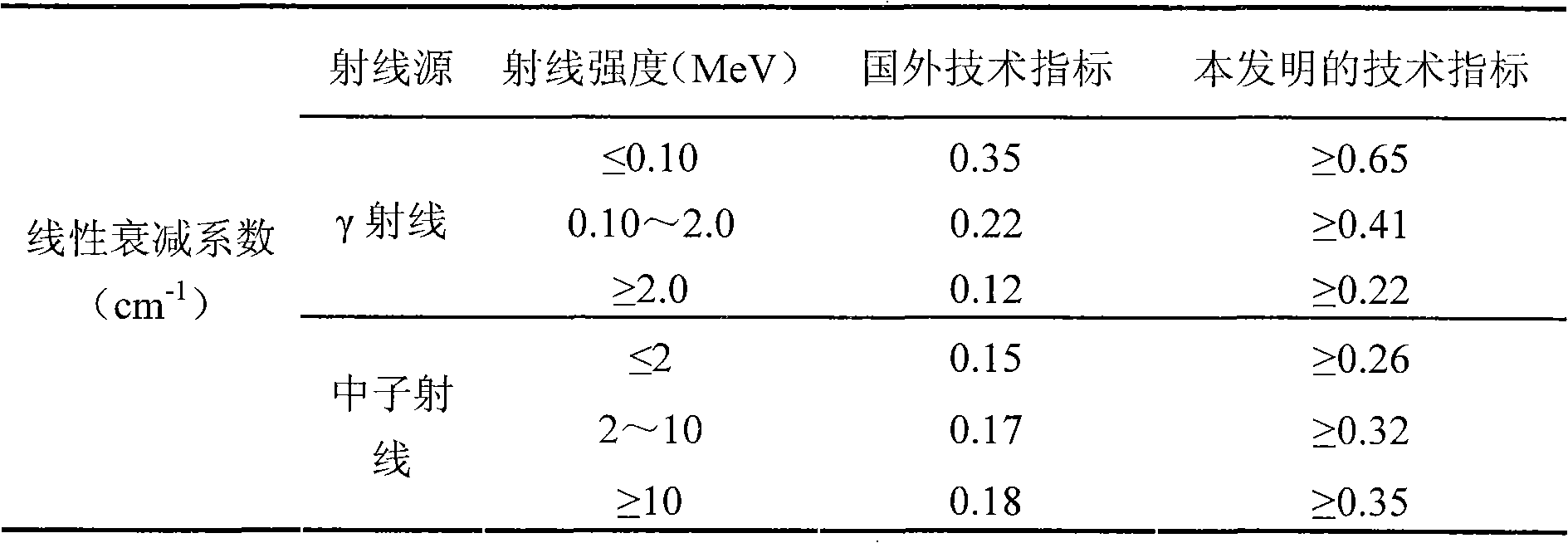

[0036] The proportioning of raw materials in each environment-friendly functional aggregate in each embodiment of table 2

[0037]

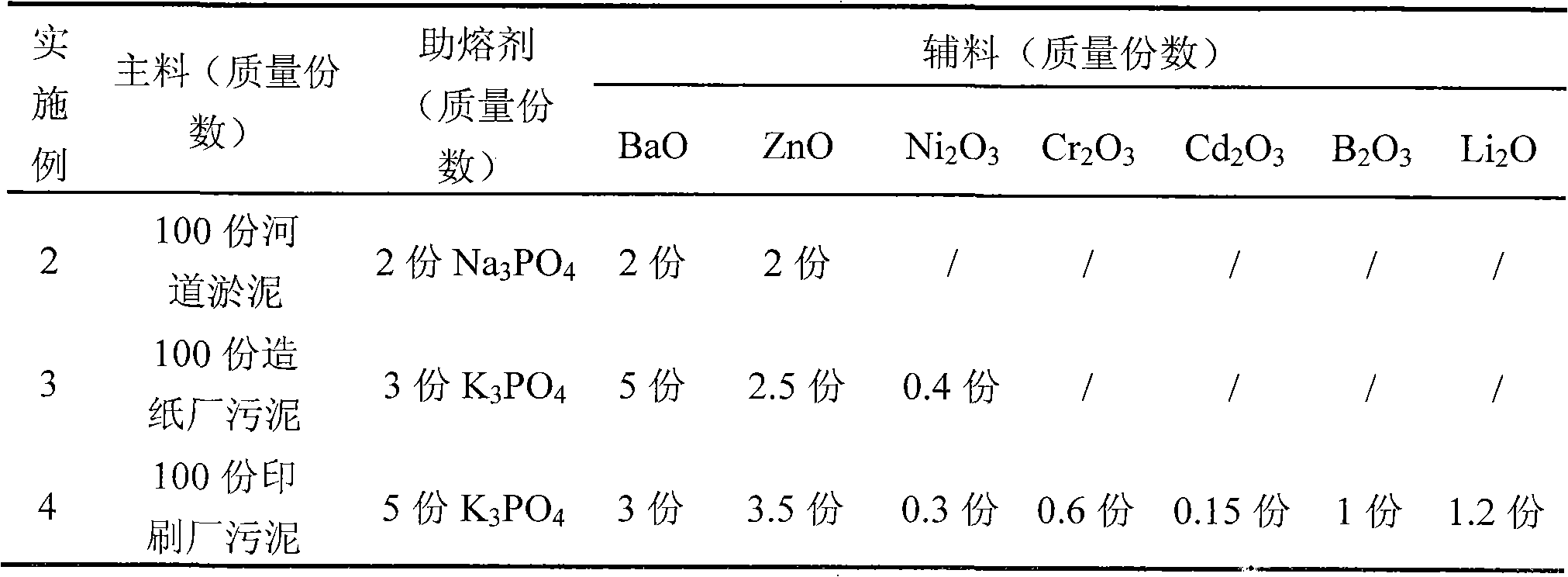

[0038] The stepped calcination system of each environment-friendly functional aggregate in each embodiment of table 3

[0039]

[0040] With reference to the method of Example 1, select raw materials according to the proportioning of raw materials in Table 2, carry out stepwise calcining according to the stepwise calcining system in Table 3, wherein the heating rate of each stage must not be higher than 10°C / min, after the calcining is completed, follow After cooling in the furnace, the environment-friendly functional aggregate can be obtained. Determination of its TCLP value is shown in Table 4, and its physical performance index is shown in Table 5.

[0041] The TCLP value of environment-friendly functional aggregate in each embodiment of table 4

[0042] ...

Embodiment 5

[0047] Example 5: Preparation of a radiation-proof concrete based on environment-friendly functional aggregates:

[0048] (1) According to the ratio: water 140kg / m 3 , the cementitious material is composed of cement and mineral admixtures, wherein cement is 200kg / m3 [the mixing ratio (mass) of barium cement and ordinary Portland cement is 1:1]; the mineral admixture is fly ash 100kg / m3 m 3 , fine aggregate 1000kg / m 3 [Environment-friendly functional aggregate and lead powder prepared in Example 1, its blending ratio (quality) is 1: 0.5], coarse aggregate 1500kg / m 3 [Environment-friendly functional aggregate and barite prepared in Example 1, its blending ratio (mass) is 1: 1], the dosage of water reducer is 0.6% of the total weight of cementitious material, and the fiber is made of steel fiber and lead-boron polyethylene, wherein the volume dosage of steel fiber is 0.5% of the total volume of the cementitious material, and the volume addition of lead-boron polyethylene fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com