Pseudoalteromonas, produced kappa-carrageenan hydrolase and preparation and application thereof

A technology of pseudoalteromonas and carrageenan, applied in hydrolytic enzymes, biochemical equipment and methods, bacteria, etc., can solve the problem of low productivity of carrageenan hydrolytic enzymes, achieve high commercial application value, and improve production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] (3) Preparation of κ-new cararatetraose sulfate

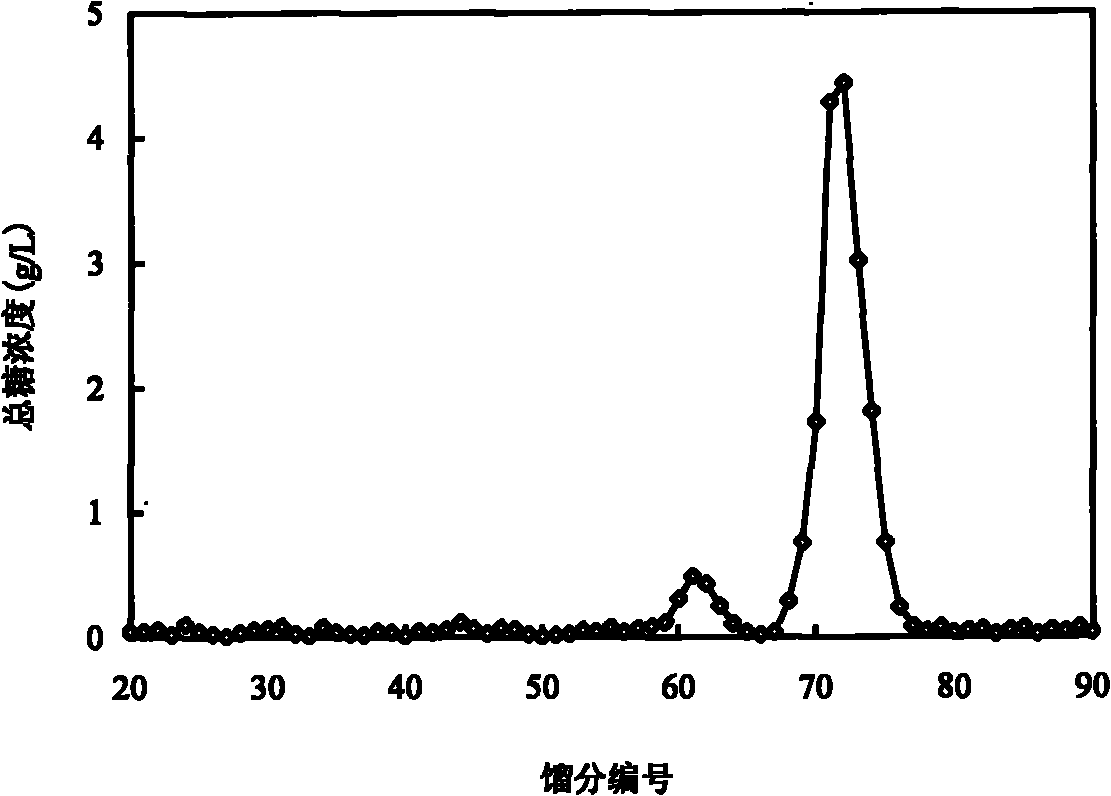

[0042] A κ-carrageenan aqueous solution with a concentration of 15 g / L was prepared, and 200 U / L of the κ-carrageenan hydrolase was added. The mixture was stirred at 200 rpm for 6 hours at the optimum temperature of 30° C. and optimum pH value of 7.5. Centrifuge at 15,000 g for 20 min to remove insoluble matter, evaporate in vacuo, and freeze-dry. The lyophilized powder was dissolved in ethanol aqueous solution with a volume ratio of 5:1, and centrifuged at 15000 g for 20 min to remove insoluble matter. After the supernatant was evaporated in vacuo to remove ethanol, it was diluted with distilled water, then loaded onto a polyacrylamine gel Bio-GelP-6DG chromatography column, and washed with 0.1M NaNO 3 The solution is eluted at a rate of 4mL / hr, and the elution curve is shown in figure 1 . Fractions 67-77 were collected, dialyzed in distilled water for 6 hr, evaporated in vacuo, and freeze-dried.

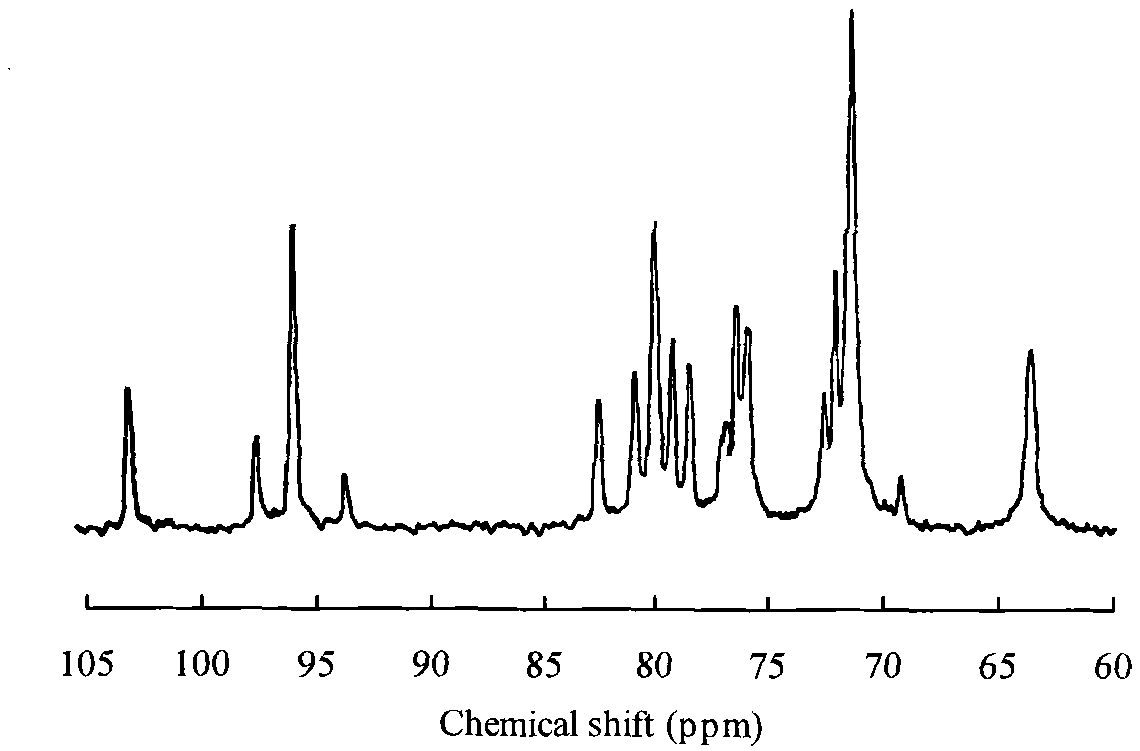

[0043] The lyoph...

Embodiment 1

[0054] The live leaves of red algae Plocamium telfairiae collected from Dongtou sea area, Oujiangkou, Wenzhou City, Zhejiang Province were cut into small discs with a diameter of about 1.5 cm, washed 3 times with sterile seawater, and immersed in 50 mL In the 500mL Erlenmeyer flask of the primary screening medium, cultivate it at 25°C for 72hr on a shaker at 200rpm. Transfer 5mL of the culture solution to a 500mL Erlenmeyer flask filled with 50mL of fresh primary screening medium, and cultivate under the same conditions. Repeat the above steps until the culture medium is obviously turbid. The turbid culture solution was diluted 10 times with sterile seawater, streaked in parallel on the agar plate containing the primary screening medium, and incubated at 25°C for 48hr. The colony that formed a transparent circle on the agar plate was transferred to a fresh agar plate containing the primary screening medium, and cultured at 25°C for 48hr. Repeat the above steps until a pure c...

Embodiment 2

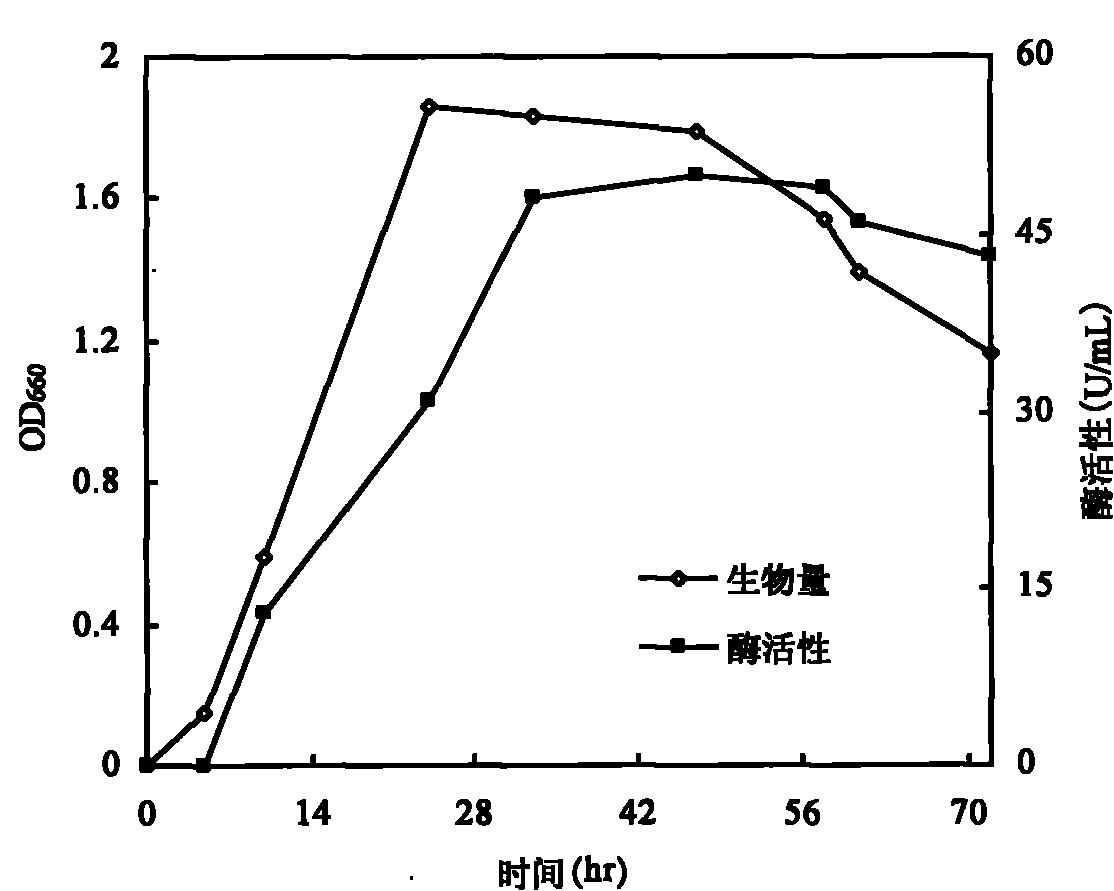

[0062] Select several different carbon sources, the concentration is 1%, and 0.1% yeast extract is used as the nitrogen source, plus 0.2% κ-carrageenan and 1.5% NaCl to prepare the medium, and the inoculum size is 10%. The culture temperature was 25° C., the rotation speed of the shaker was 200 rpm, and the κ-carrageenan hydrolase fermentation of Pseudoalteromonas (Pseudoalteromonas) WZU4771 was carried out. After culturing for 48 hours, the results are shown in Table 1. Glucose is the best carbon source.

[0063] Table 1 Effect of carbon source on κ-carrageenan hydrolase fermentation

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com