Method for preparing super-pure nitric acid

A technology of ultra-pure nitric acid and nitric acid, which is applied in the direction of nitric acid, nitrogen oxides/oxo acids, etc., can solve the problems of unstable product quality, large fluctuations in purity, high cost, etc., to overcome unstable product quality, improve purity, The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

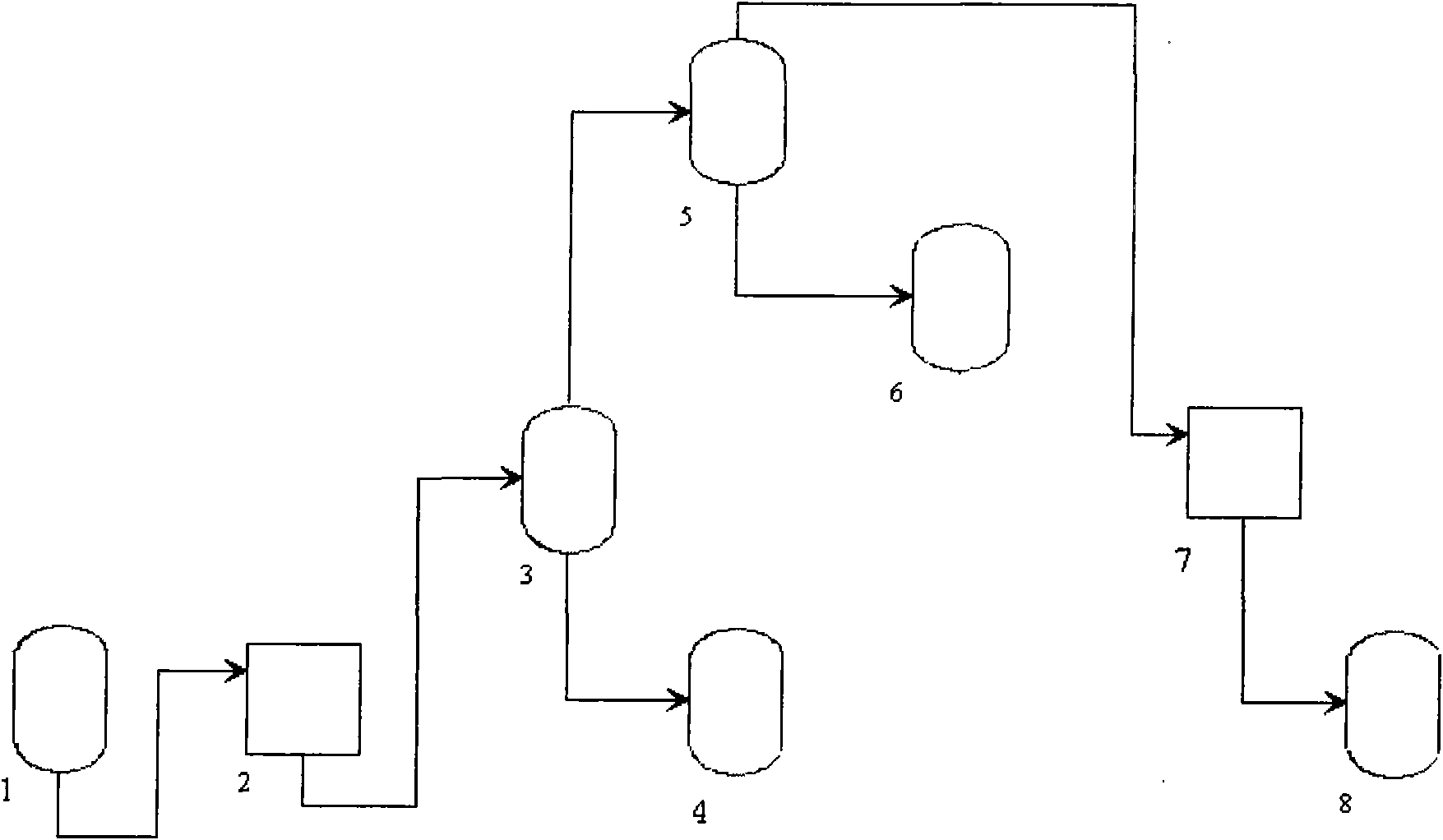

Method used

Image

Examples

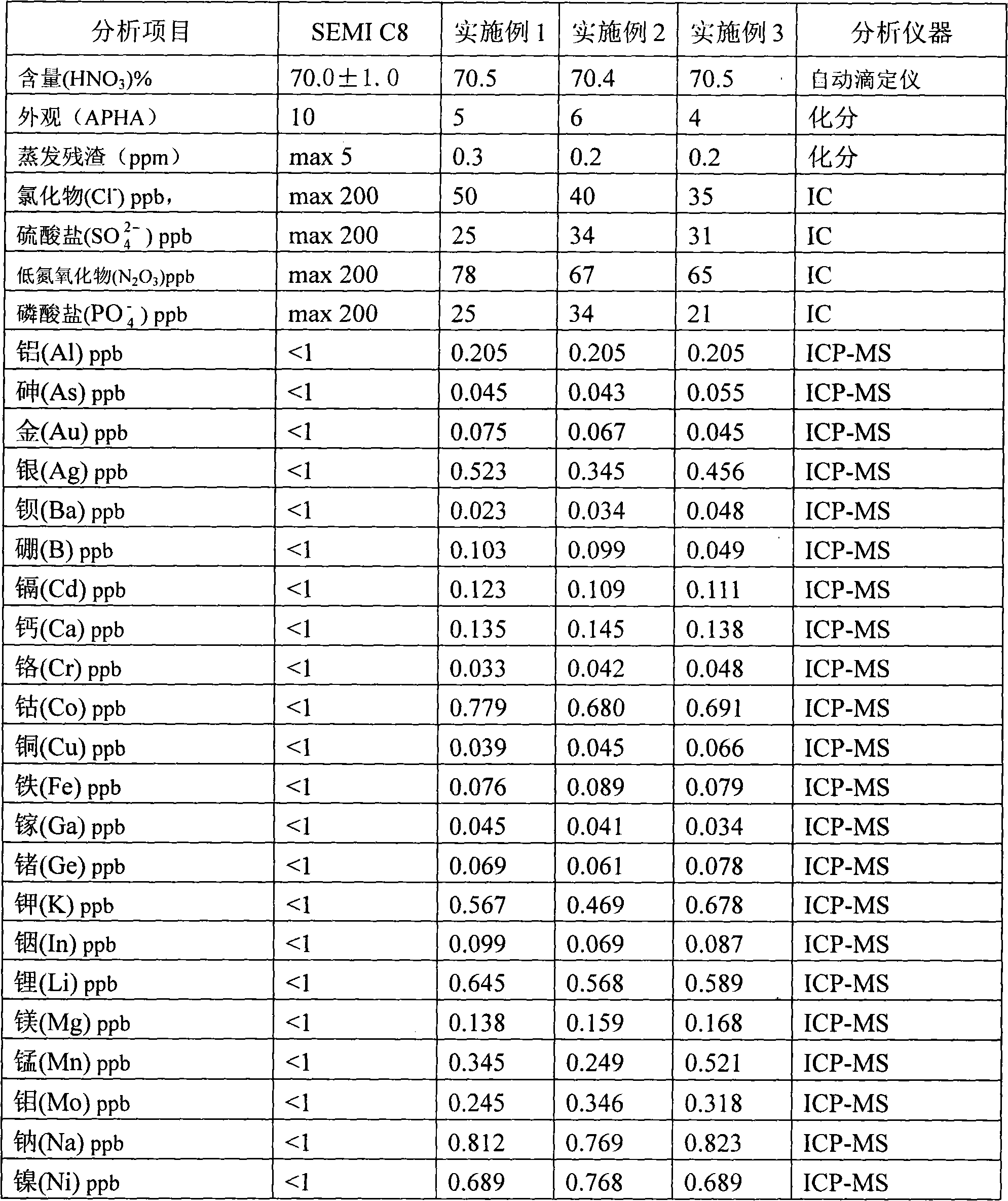

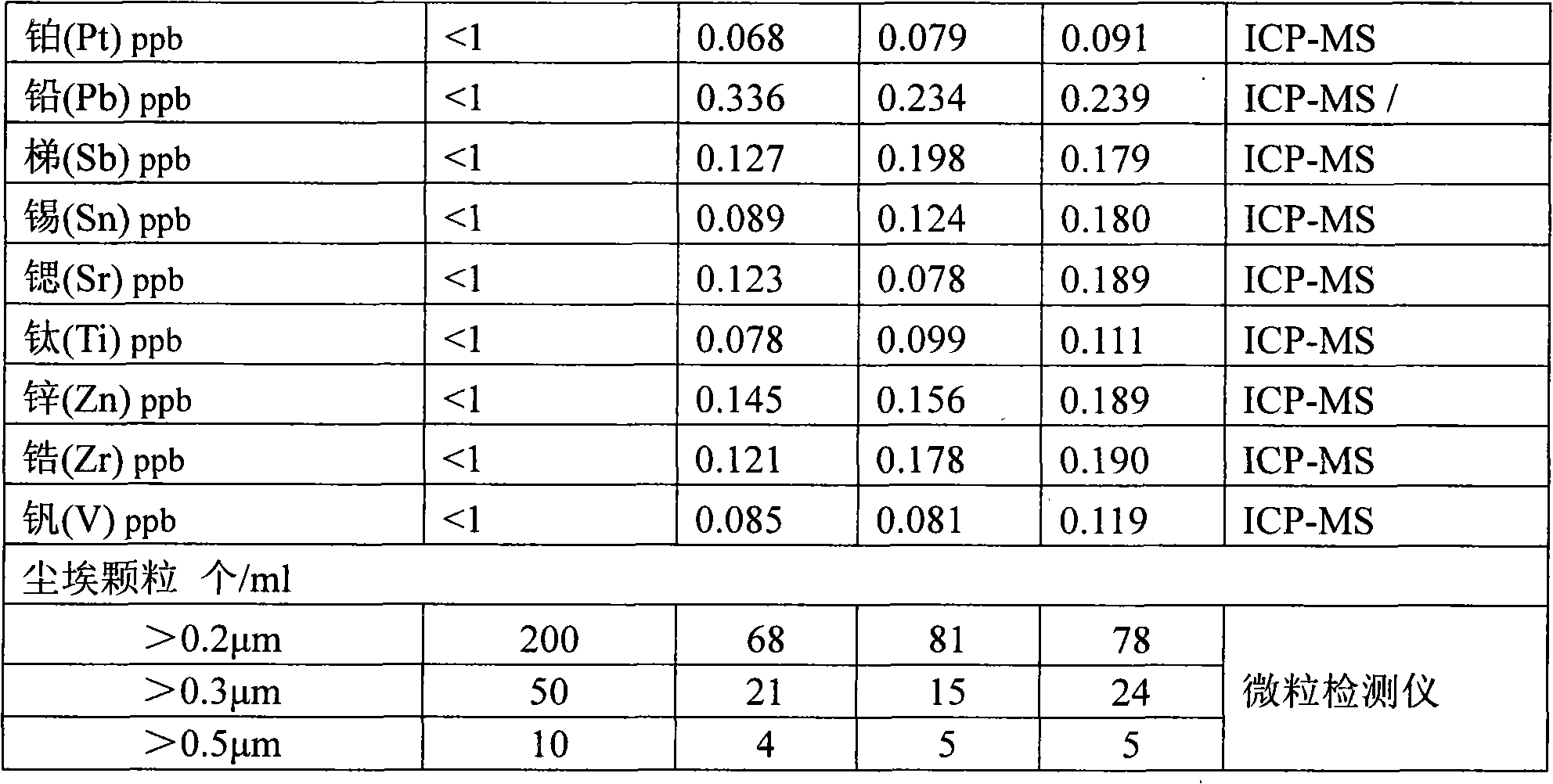

Embodiment 1

[0021] (1) Preparation of composite film of dibenzo-18-crown-6 and solid support: mix bis-benzo-18-crown-6 and kaolin (the main components are silicon dioxide, aluminum oxide and water) by mass Mix at a ratio of 1:3, grind to a uniform size of 200-300 mesh, form a billet, dry at low temperature, and sinter at a high temperature of 800-900°C to prepare dibenzo-18-crown-6 and a solid phase carrier with a pore size of 0.1 μm composite film.

[0022] (2) 71.0wt% industrial-grade nitric acid passes through a membrane filter composed of 0.1 μm diphenyl-18-crown-6 and solid-phase carrier composite membrane at room temperature and a pressure of 0.5 MPa, and the filtrate obtained by filtering is carried out at 120° C. One-stage rectification, two-stage series rectification at 130°C, respectively collect heavy waste acid and light waste acid (recovered for comprehensive utilization), and the condensed liquid is subjected to two-stage filtration through a membrane filter to obtain super ...

Embodiment 2

[0024] (1) Preparation of composite membrane of dibenzo-18-crown-6 and solid support: mix bis-benzo-18-crown-6 with silica gel, molecular sieve or kaolin (the main components are silicon dioxide, aluminum oxide and Water) is mixed according to the mass ratio of 1:6, ground into 200-300 mesh fine powder, then mixed evenly with the binder (polyvinyl alcohol), formed into a billet, dried at low temperature, at 800-900°C The composite membrane of dibenzo-18-crown-6 and solid phase support with a pore size of 0.15 μm was prepared by sintering.

[0025] (2) 70.7wt% industrial-grade nitric acid passes through a membrane filter composed of 0.15 μm diphenyl-18-crown-6 and solid-phase carrier composite membrane at room temperature and a pressure of 0.25 MPa, and the filtrate obtained by filtering is carried out at 45° C. One-stage rectification, two-stage series rectification at 55°C, while heavy waste acid and light waste acid are collected (recycled for comprehensive utilization), and...

Embodiment 3

[0027] (1) Preparation of composite film of dibenzo-18-crown-6 and solid support: mix bis-benzo-18-crown-6 and kaolin (the main components are silicon dioxide, aluminum oxide and water) by mass Mix at a ratio of 1:10, grind into 200-300 mesh fine powder, then mix evenly with a binder (polyvinyl alcohol), form a billet, dry at low temperature, and sinter at a high temperature of 800-900°C to obtain the pore size It is a composite film of 0.2μm dibenzo-18-crown-6 and solid support.

[0028] (2) 70.5wt% industrial-grade nitric acid passes through a membrane filter composed of 0.2 μm diphenyl-18-crown-6 and solid-phase carrier at room temperature and a pressure of 0.1 MPa, and the filtrate obtained by filtering is subjected to a first-stage process at 50° C. Rectification, two-stage series rectification at 60°C, while collecting heavy waste acid and light waste acid (recycled for comprehensive utilization), the condensed liquid is subjected to secondary filtration through a membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com