Method for preparing adamantyl unsaturated ester

An adamantyl and unsaturated technology, which is applied in the preparation of carboxylic acid halides, photosensitive materials for optomechanical equipment, coatings, etc., can solve the problem of reduced yield of adamantyl esters, which is unfavorable for large-scale production, and the purpose The problems such as the reduction of the yield of the product can be solved, and the effect of easy operation of the reaction process, fast reaction speed and improved conversion rate can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

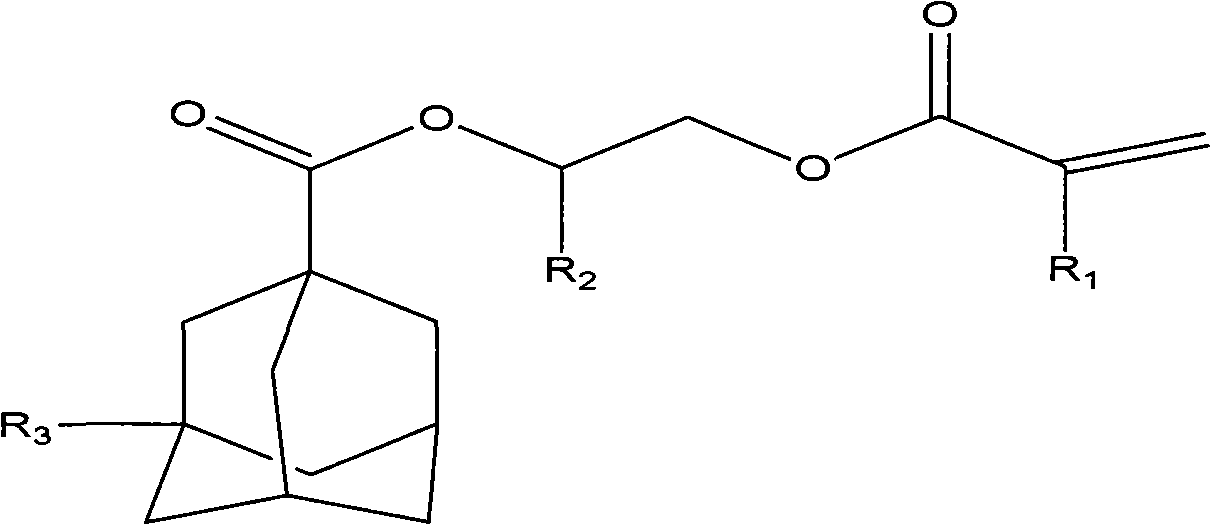

[0039] Preparation of ethylene glycol diester of acrylate-1-adamantanecarboxylate

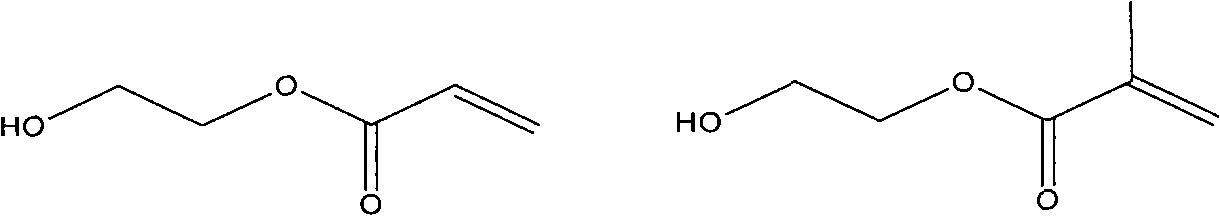

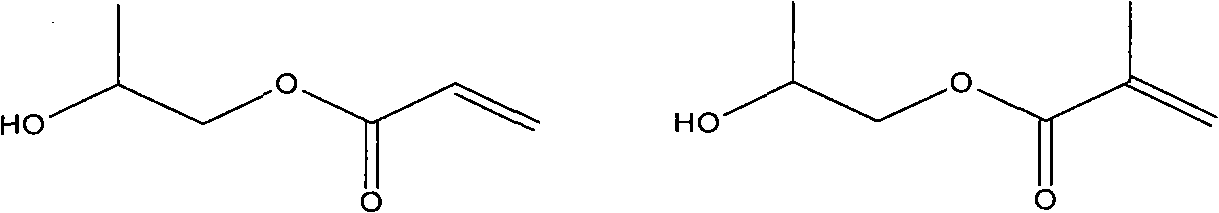

[0040] After adding 2g of hydroxyethyl acrylate, 2.6g of triethylamine and 100mL of dichloromethane into a three-necked flask with a mechanical stirring device, the reaction temperature was 0-5°C, and 4.1g of 1-adamantanecarbonyl chloride was weighed, Then dissolve it in 40mL of dichloromethane, drop it into a three-necked flask within 3 hours, after the dropwise addition, continue to stir for 5 hours, let it stand overnight, and filter it with suction to obtain a light yellow liquid, which is washed with dilute hydrochloric acid solution (1mol / L), NaHCO 3 (1mol / L) solution and distilled water to wash the light yellow liquid (retained liquid is the upper layer), and use anhydrous Na 2 SO 4 Dry, filter, and remove the solvent to obtain a light yellow acrylic acid-1-adamantanecarboxylic acid ethylene glycol diester solid, whose structural formula is as follows

[0041]

[0042] Ethylene gl...

Embodiment 2

[0044] Preparation of ethylene glycol diester of acrylic acid-3-formyl chloride-1-adamantanecarboxylate

[0045] After adding 2g of hydroxyethyl acrylate, 2.6g of triethylamine and 100mL of dichloromethane into a three-necked flask with a mechanical stirring device, the reaction temperature is 0-5°C, and weigh 5.4g of 1,3-adamantanedi formyl chloride, and then dissolved in 40mL of dichloromethane, drop it into the three-necked flask within 3 hours, after the dropwise addition, continue to stir for 5 hours, let it stand overnight, and filter it with suction to obtain a light yellow liquid, which is washed with dilute hydrochloric acid Solution (1mol / L), NaHCO 3 (1mol / L) solution and distilled water to wash the light yellow liquid (retained liquid is the upper layer), and use anhydrous Na 2 SO 4 Dry, filter, and remove the solvent to obtain a light yellow acrylic acid-3-formyl chloride-1-adamantanecarboxylic acid ethylene glycol diester solid, whose structural formula is as fo...

Embodiment 3

[0049] Preparation of ethylene glycol diester of methacrylic acid-1-adamantanecarboxylate

[0050] After adding 2g of hydroxyethyl methacrylate, 3.3g of tripropylamine and 200mL of dichloromethane into a three-necked flask with a mechanical stirring device, the reaction temperature is 0-5°C, and weigh 3.7g of 1-adamantanecarbonyl chloride , and then dissolved it in 60mL of dichloromethane, and dropped it into a three-necked flask within 3 hours. After the dropwise addition, continued to stir for 5 hours, left it standing overnight, and filtered it with suction to obtain a light yellow liquid, which was washed with dilute hydrochloric acid solution ( 1mol / L), NaHCO 3 (1mol / L) solution and distilled water to wash the light yellow liquid (retained liquid is the upper layer), and use anhydrous Na 2 SO 4 Dry, filter, and remove the solvent to obtain a light yellow methacrylic acid-1-adamantanecarboxylic acid ethylene glycol diester solid, whose structural formula is as follows

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com