Method for preparing lithium titanate precursor and lithium iron phosphate precursor by comprehensively utilizing ilmenite

A lithium iron phosphate and precursor technology is applied in the field of comprehensively utilizing ilmenite to prepare lithium titanate and lithium iron phosphate precursors, and achieves the effects of simple process flow, excellent electrochemical performance and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Separation of ferro-ilmenite: the ilmenite is ball-milled until the particle size is below 5 microns, and the ilmenite is leached under normal pressure with sulfuric acid with a mass concentration of 5%, the mass ratio of sulfuric acid to ilmenite is 1.8, and the leaching temperature is 100 degrees Celsius , The leaching time is 10 hours. After the leaching is completed, the slurry is cooled to room temperature, and filtered to obtain a filter residue and a filtrate.

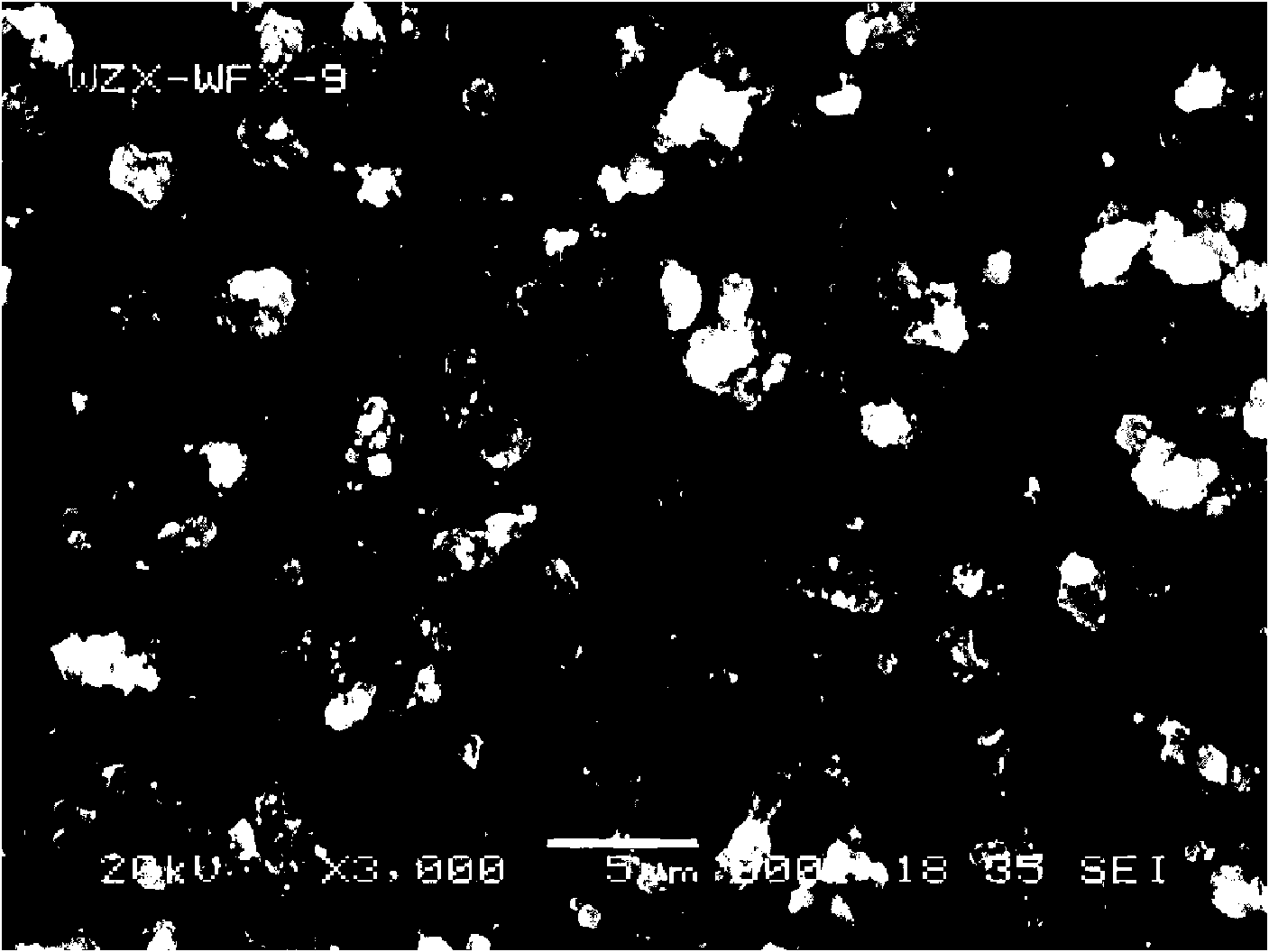

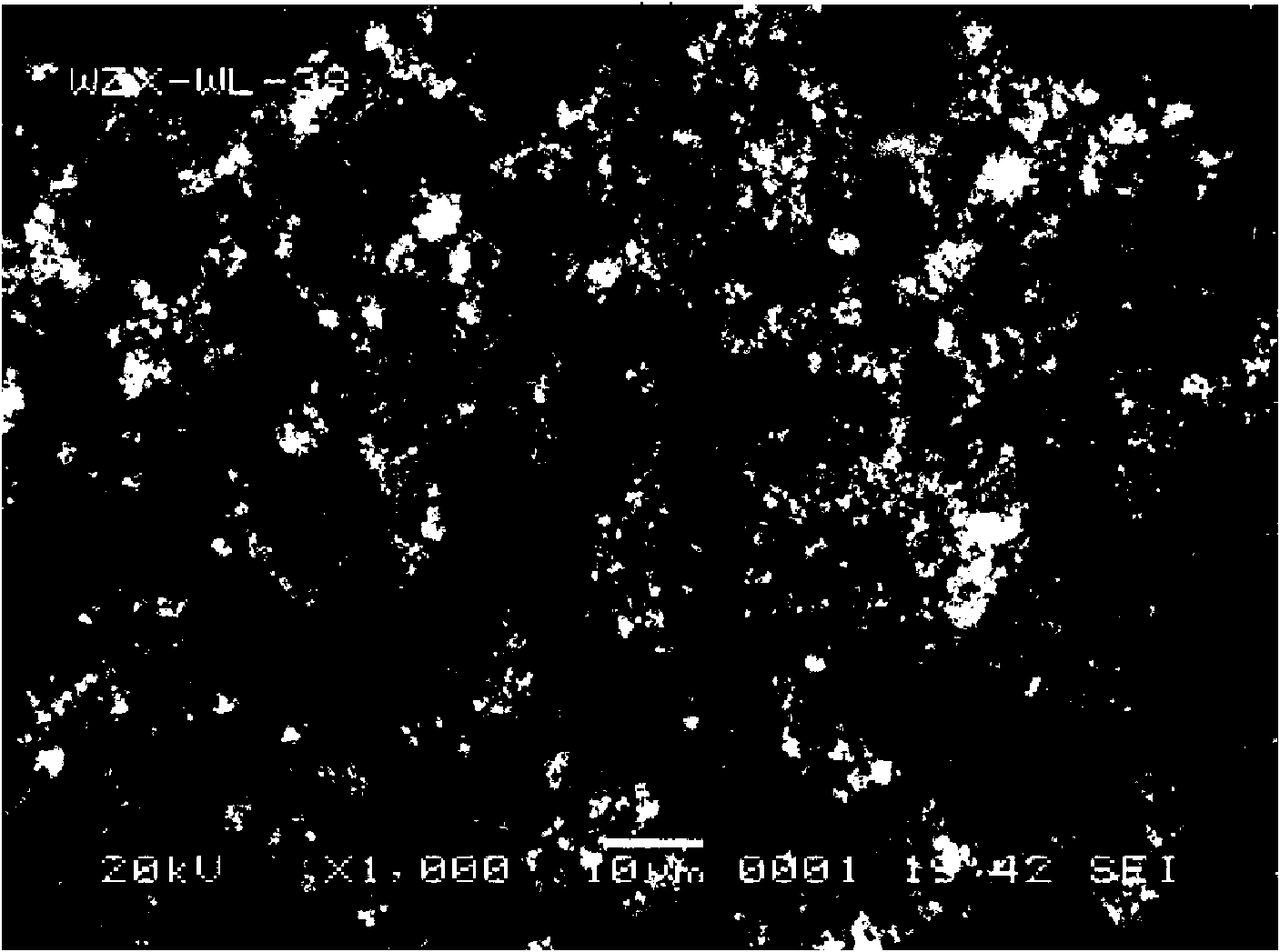

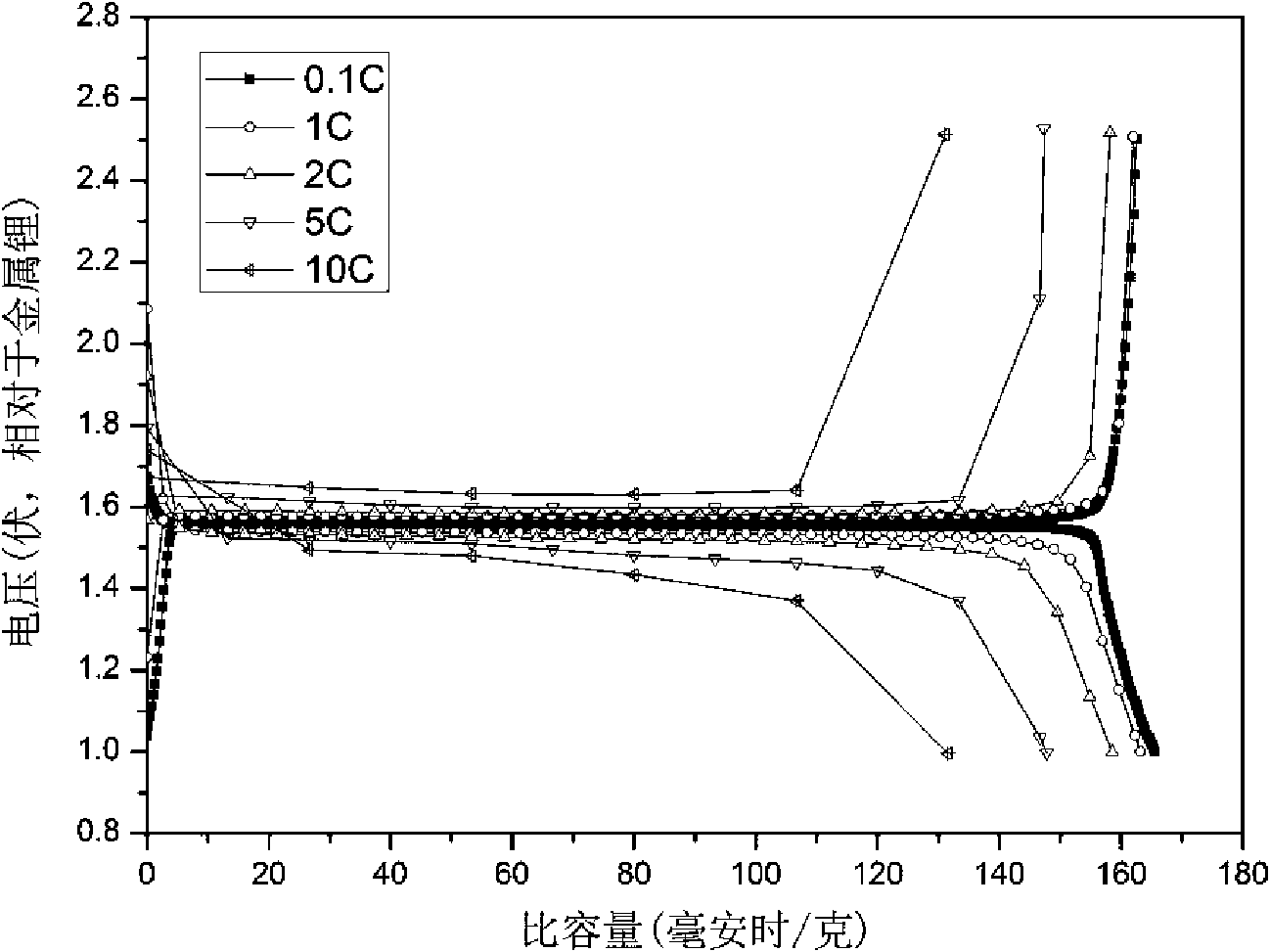

[0032] (2) Preparation of lithium titanate precursor: the filter residue obtained in step (1) was washed twice with sulfuric acid with a mass concentration of 5%, and then dissolved with sulfuric acid with a mass concentration of 85%, and the molar ratio of sulfuric acid to titanium was 1.5: 1. Add deionized water to dilute until the molar concentration of titanium is 0.5mol / L, add ammonium oxalate, the molar ratio of ammonium oxalate to titanium is 2:1, react for 1 hour, cool to 3 degrees Celsius, le...

Embodiment 2

[0035] (1) Ferro-ilmenite separation: the ilmenite is ball-milled to a particle size of less than 5 microns, and the ilmenite is leached under normal pressure with sulfuric acid with a mass concentration of 15%. The mass ratio of sulfuric acid to ilmenite is 2.5, and the leaching temperature is 120 Celsius, the leaching time is 0.5 hours. After the leaching is completed, the slurry is cooled to room temperature, and filtered to obtain a filter residue and a filtrate.

[0036] (2) Preparation of lithium titanate precursor: the filter residue obtained in step (1) was washed twice with sulfuric acid with a mass concentration of 10%, and then dissolved with sulfuric acid with a mass concentration of 90%, and the molar ratio of sulfuric acid to titanium was 3: 1. Dilute with deionized water until the molar concentration of titanium is 2 mol / L, add oxalic acid, the molar ratio of oxalic acid and titanium is 1:1, react for 4 hours, cool to 1 degree Celsius, let stand for 0.5 hours, f...

Embodiment 3

[0040] (1) Separation of ferro-ilmenite: the ilmenite is ball-milled to a particle size of less than 5 microns, and the ilmenite is leached under normal pressure with sulfuric acid with a mass concentration of 25%. The mass ratio of sulfuric acid to ilmenite is 1.2, and the leaching temperature is 80 Celsius, the leaching time is 20 hours. After the leaching is completed, the slurry is cooled to room temperature, and filtered to obtain a filter residue and a filtrate.

[0041] (2) Preparation of lithium titanate precursor: the filter residue obtained in step (1) was washed twice with sulfuric acid with a mass concentration of 1%, and then dissolved with sulfuric acid with a mass concentration of 75%, and the molar ratio of sulfuric acid to titanium was 1: 1. Dilute with deionized water until the molar concentration of titanium is 0.1mol / L, add sodium oxalate, the molar ratio of sodium oxalate and titanium is 4:1, react for 10 minutes, cool to 5 degrees Celsius, let stand for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com