Control system of pumping system

A control system and oil pumping technology, which is applied to the automatic control system of drilling, production fluid, drilling equipment, etc. It can solve the problems of low oil production cost, low system efficiency, very large power loss, and accelerated motor temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

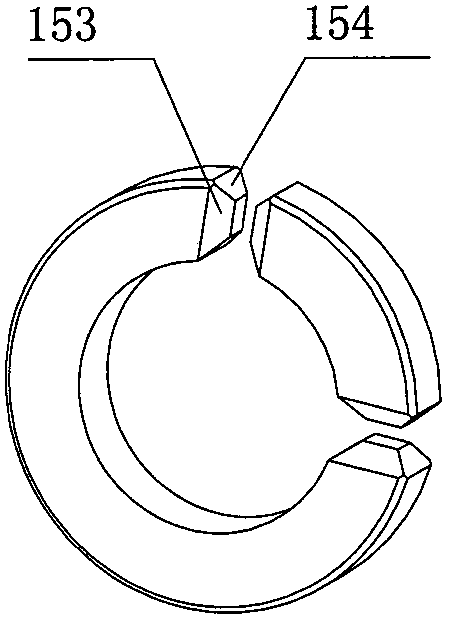

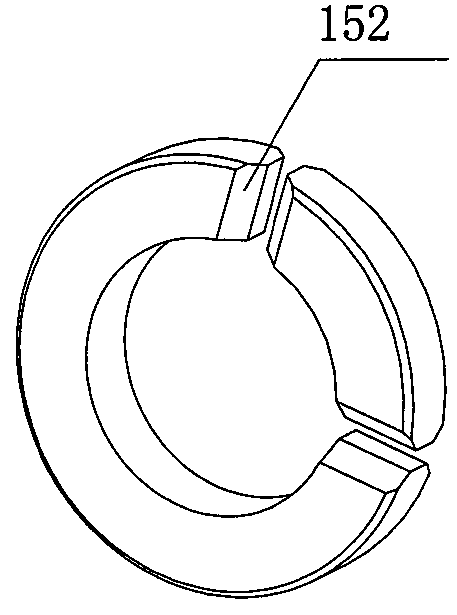

[0147] Figure 19 is an exploded schematic diagram of a magnetoelectric sensor solution equipped with two magnetic induction elements according to the first embodiment of the present invention. The magnetoelectric sensor includes inductive element 710, circuit board 711, magnetic conduction ring 712, stainless steel cover 713, magnetic steel ring 715 and casing (not shown), and magnetic steel ring 715 is installed on the motor tail shaft 716, and the rest It can be installed on the stainless steel cover 713 of the high-voltage threading sealing assembly 714 . The feature of this solution is that the magnetoelectric sensor has two magnetic induction elements, and the magnetic permeable ring 712 is also composed of two parts, one is a 1 / 4 magnetic ring, and the other is a 3 / 4 magnetic ring. Two incomplete magnetic rings form two slits for cooperating with two magnetic induction elements.

[0148] Figure 20 is a block diagram of a signal processing device of a magnetoelectric...

no. 2 example

[0198] In the second embodiment, there are two magnetic steel rings and two magnetic permeable rings, and there are correspondingly two columns of magnetic induction elements. These are the key components of the magnetoelectric sensor, and the installation and structure of other components are different from those of the other components. The similarities in the first embodiment are not repeated here.

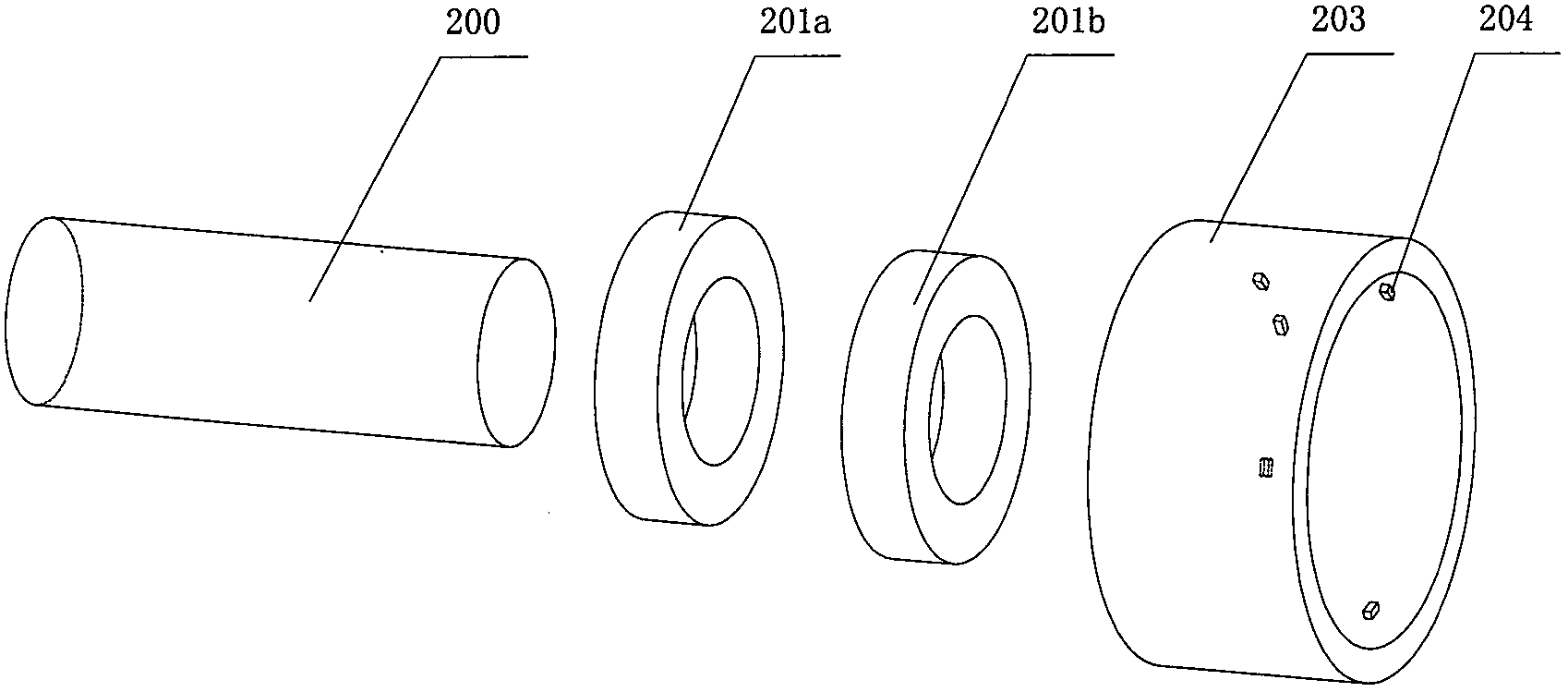

[0199] Figure 24 is an exploded perspective view of key components of the magnetoelectric sensor solution according to the second embodiment of the present invention. Figure 25 is a schematic diagram of the installation of the magnetoelectric sensor solution according to the second embodiment of the present invention. The magnetoelectric sensor of this embodiment includes a magnetic steel ring and a stator that wraps the magnetic steel ring inside. The magnetic steel ring includes a first magnetic steel ring 201a and a second magnetic steel ring 201b and a first magnetic per...

no. 3 example

[0223] In the third embodiment, the number of each component and its installation scheme are similar to those in the second embodiment, the difference is the magnetization method of the magnetic steel ring and the arrangement position of the magnetic induction element.

[0224] Figure 37 is an exploded perspective view of the magnetoelectric sensor according to the third embodiment. On the frame 306 , two rows of magnetic induction elements 307 are respectively arranged corresponding to the magnetic steel ring 302 and the magnetic steel ring 303 . Only one column of magnetic induction elements is shown in the figure. For the convenience of illustration, the first column of magnetic induction elements, that is, the multiple magnetic induction elements corresponding to the magnetic steel ring 302 and the magnetic permeable ring 304, are represented by magnetic induction elements 307, and the second column of magnetic induction elements That is, a plurality of magnetic inductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com