Method for preparing sample for measuring thermal expansion coefficient of sprayed coating

A thermal expansion coefficient and sample technology, which is used in the preparation of samples for measuring the thermal expansion coefficient of spray coatings, can solve the problems of inability to replicate the authenticity of the spray coating process, different coating structures, structures, and different expansion coefficients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

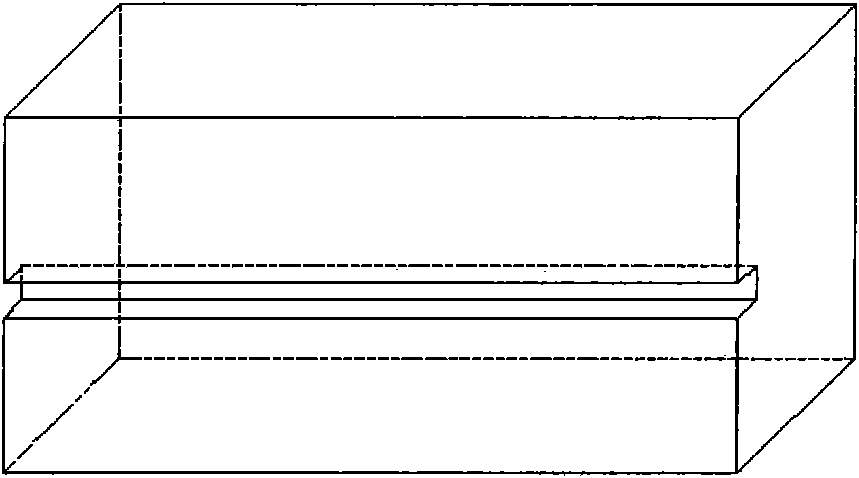

[0020] This embodiment is plasma sprayed Al 2 o 3 Preparation of samples for the determination of the coefficient of thermal expansion of the coating. A groove with a size of 70 mm × 7 mm × 12 mm (length × depth × width) is processed on the cuboid graphite substrate ( figure 1 Shown), use cleaning gasoline, alcohol or acetone to degrease the groove part (the degreasing method of the following examples is the same as this) and low-pressure sandblasting and texturing. When the surface of the groove is sandblasting and texturing, use a smaller force to Do not destroy the shape and size of the groove edge of the graphite substrate, and then use the plasma spraying process to spray Al on the graphite substrate 2 o 3 During intermittent spraying, ensure that the temperature rise of the substrate surface is lower than 150°C to prevent premature separation of the coating from the substrate due to overheating until Al 2 o 3 Cover the groove completely, and then use a hacksaw to cu...

Embodiment 2

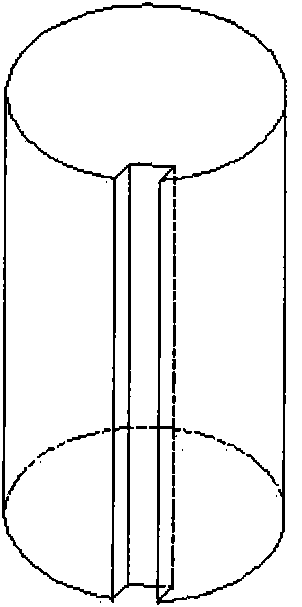

[0022] This embodiment is supersonic flame spraying (HVOF) NiCr-Cr 3 C 2 Preparation of samples for the determination of the coefficient of thermal expansion of the coating. A groove with a size of 70 mm × 7 mm × 12 mm (length × depth × width) is processed on the cylindrical graphite substrate ( figure 2 Shown), degreasing the groove part and low-pressure sandblasting texturization, using a small force when sandblasting the surface of the groove, so as not to damage the shape and size of the groove edge of the graphite matrix, and then using a supersonic flame Spraying NiCr-Cr on Graphite Substrate by Spraying Process 3 C 2 Coating, during which an intermittent spraying process is used to prevent premature separation of the coating from the substrate due to overheating, until NiCr-Cr 3 C 2 Cover the groove completely, then use a hacksaw to cut along the edge of the graphite outside the groove, and take out the NiCr-Cr 3 C 2 The sample is then ground to a size of 65mm×5...

Embodiment 3

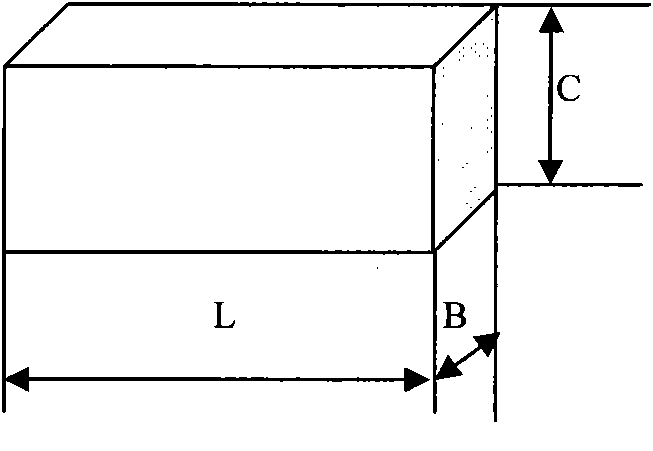

[0024] This example is the preparation of a sample for measuring the coefficient of thermal expansion of an arc sprayed stainless steel coating. A groove with a size of 40mm×6mm×7mm (length×depth×width) is processed on the cuboid gypsum substrate ( figure 1 As shown), degrease the groove part and roughen it with low pressure sandblasting. When sandblasting the surface of the groove, use a small force to ensure that the shape and size of the groove edge of the gypsum matrix are not damaged, and then use the arc spraying process Spray the stainless steel coating on the gypsum base, and use the intermittent spraying process until the stainless steel completely covers the groove, then use a hacksaw to cut along the edge of the gypsum outside the groove, take out the stainless steel sample, and then grind it. To a size of 25mm×4mm×4mm (length×height×width), the parallelism deviation of the left and right end faces is less than 0.05 ( image 3 shown). The samples at this time can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com