Oled device employing alkali metal cluster compounds

A compound and alkali metal salt technology, applied in the field of alkali metal cluster compounds, can solve problems such as performance limitations, and achieve the effects of improving efficiency, reducing device driving voltage, and improving working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

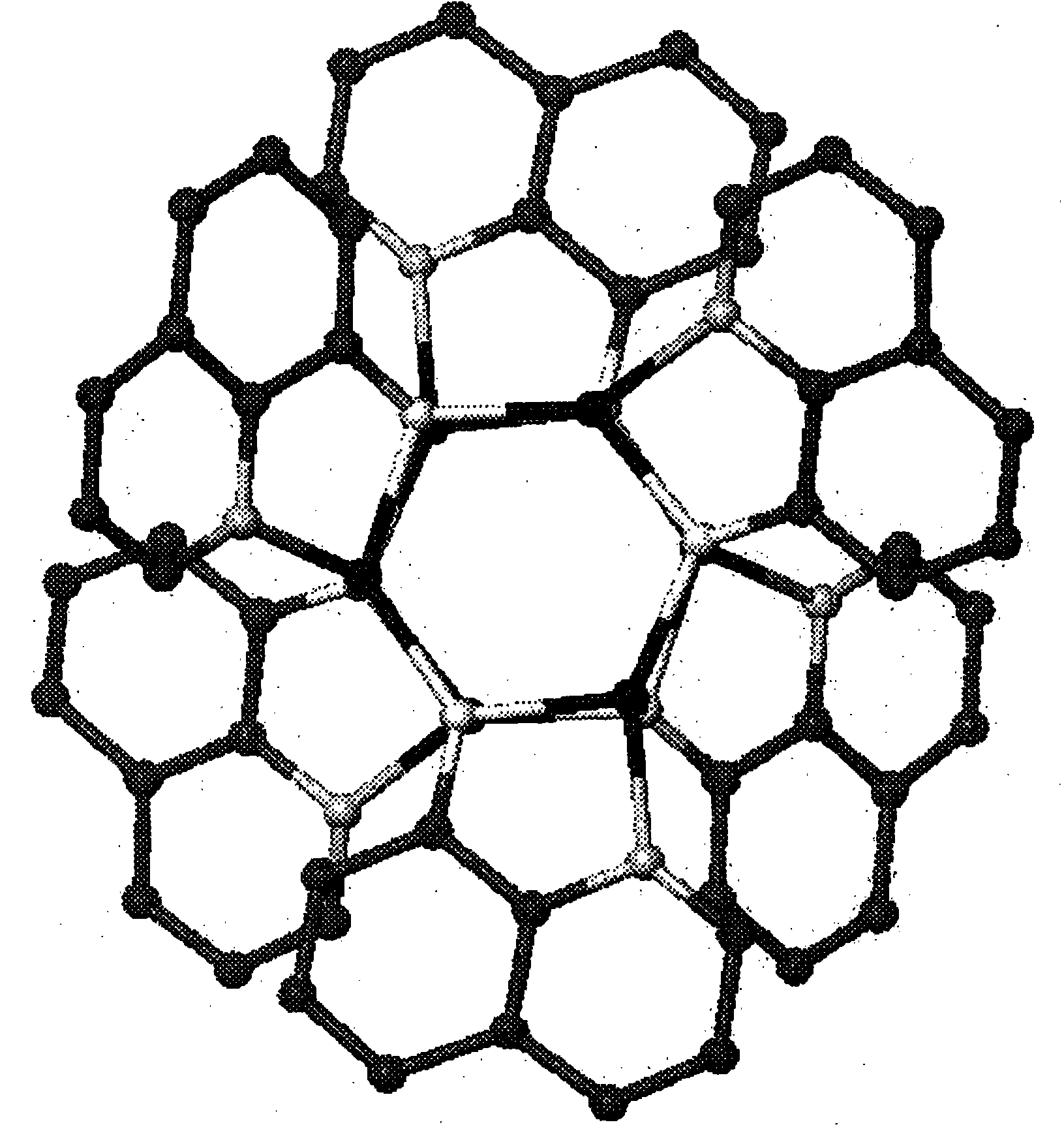

[0423] In process figure 1 The synthesis of 2-(1,10-phenanthrolin-2-yl)-phenol lithium (5), the raw material required for the preparation of Inv-1, is outlined in a diagram.

[0424] plan 1

[0425]

[0426]

[0427] 2-Chloro-1,10-phenanthroline (1):

[0428] 2-Chloro-1,10-phenanthroline was prepared from 1,10-phenanthroline according to the steps of BEHalcrow, Wm.O.Kermack, Journal of the Chemical Society (1946), 155-7, and satisfactorily The yield is isolated.

[0429] 2-(2-Methoxyphenyl)-1,10-phenanthroline hydrochloride (3):

[0430] Combine 2-chloro-1,10-phenanthroline (5.9g, 27.5mMole), 2-methoxyphenylboronic acid (2) (5g, 33mMole), tetrakis(triphenylphosphine)palladium (0)( 1g, 0.825mMole), 2M-Na 2 CO 3 (33mL, 66mMole) and ethanol (8mL) were suspended in toluene (70mL), heated to 100°C and fully stirred for 24 hours. At the end of this time, the reaction was cooled, diluted with ethyl acetate (200 mL), and the aqueous layer was removed. The organic layer was washed with water...

Embodiment 1

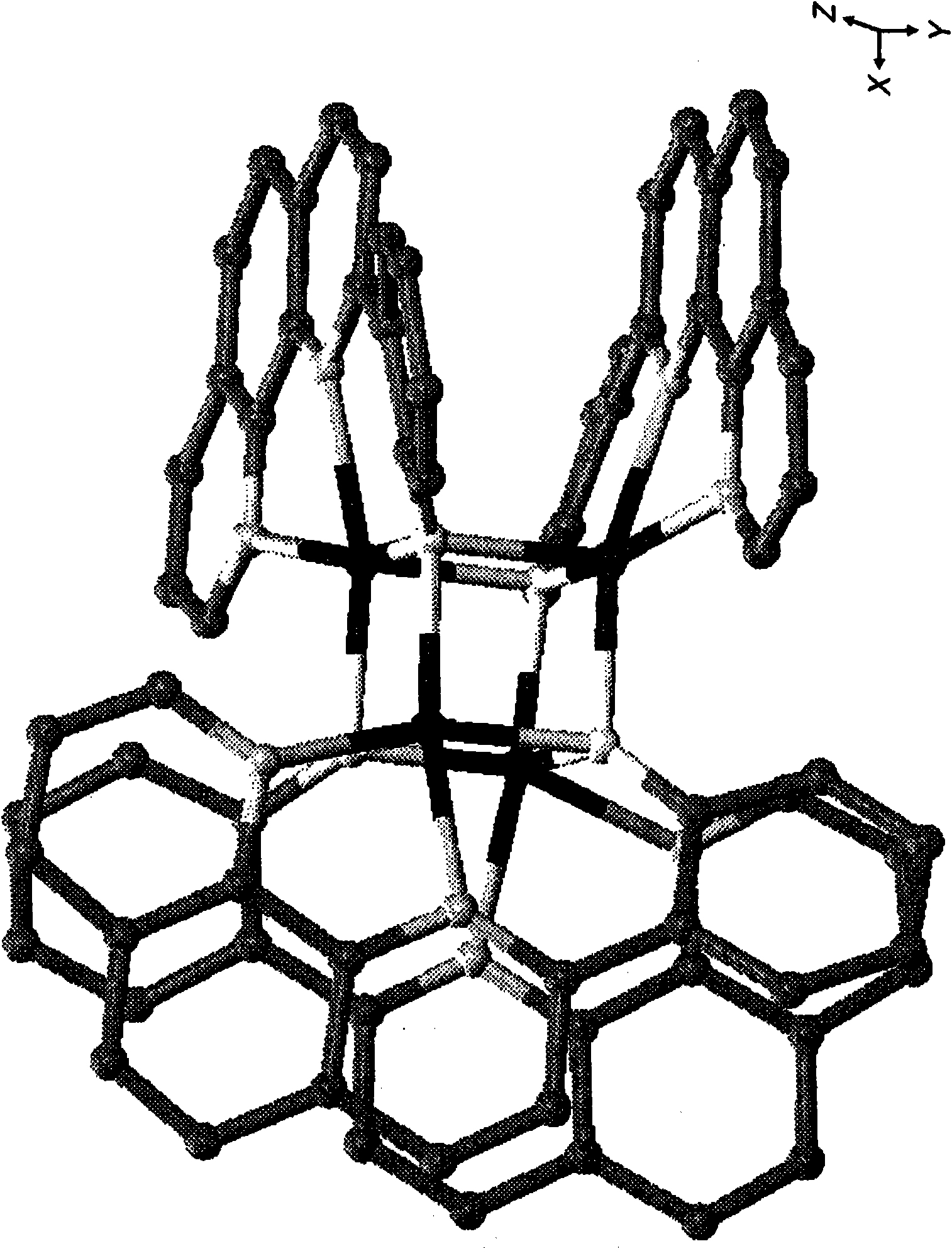

[0435] Example 1 (Route A)-Synthesis of compound Inv-1 of the present invention in solvent:

[0436]

[0437] Lithium quinolate (6) (3g, 19.86mMole) and 2-(1,10-phenanthrolin-2-yl)-lithium phenoxide (5) (2.76g, 9.92mMole) in o-dichlorobenzene ( The mixture in 50 mL) was slowly refluxed for 45 minutes. The pale yellow solution was cooled and crystallization was induced by scraping the walls of the flask. The Inv-1 crystals were filtered out, washed thoroughly with ether and dried. The yield of the product Inv-1 was 4.0 g. Before being used to manufacture devices, the Inv-1 is heated at 290℃ / 10 -3 mm Hg sublimation.

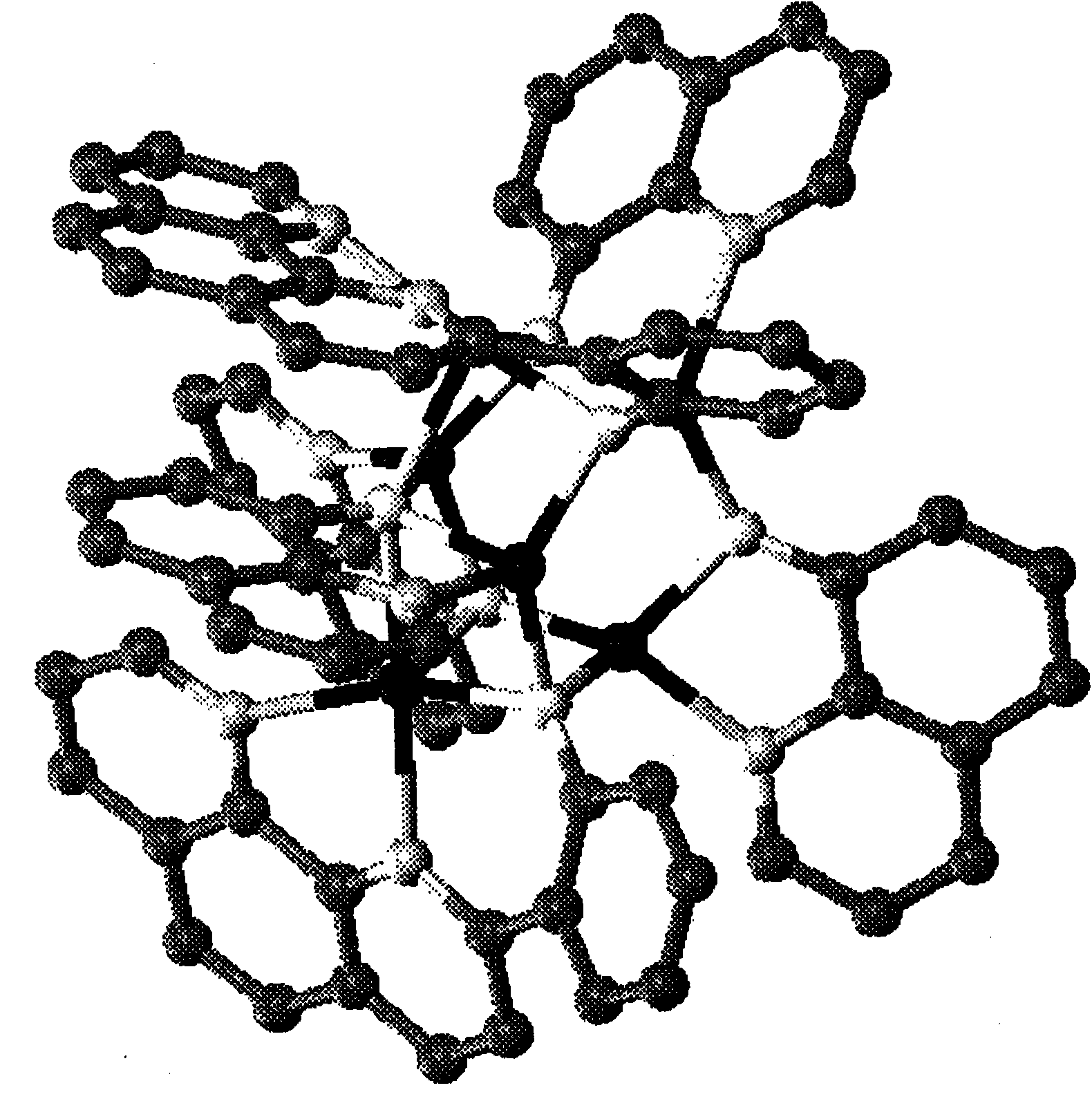

[0438] Example 1 (Route B):-Alternative synthesis of the compound of the present invention Inv-1 by direct sublimation:

[0439] Combine lithium quinolate (5) (1.5g, 9.93mMole) and 2-(1,10-phenanthrolin-2-yl)-phenol lithium (6) (1.4g, 4.96) in a mortar with a pestle. mMole) ground into a dense mixture. Then at 290℃ / 10 -3 mm Hg sublimed the material mixture to obtain...

Embodiment 2

[0440] Example 2 (Route B):-Synthesis of the compound of the invention Inv-5 by direct sublimation:

[0441] Grind lithium pentafluorophenolate (1g, 1.32mMole) and 2-(1,10-phenanthrolin-2-yl)-lithium phenolate (6) (0.37g, 0.66mMole) in a mortar with a pestle. Dense mixture. Then at 235℃ / 10 -3 mm Hg sublimed the material mixture to obtain 0.2 g of Inv-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com