Energy reclaiming sludge reduction method

A technology for sludge reduction and energy recovery, applied in energy wastewater treatment, biological sludge treatment, biochemical equipment and methods, etc., can solve the problems of long residence time, slow digestion rate, low treatment efficiency, etc. Effects of slime reduction, promotion of dissolution, and improvement of anaerobic digestion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

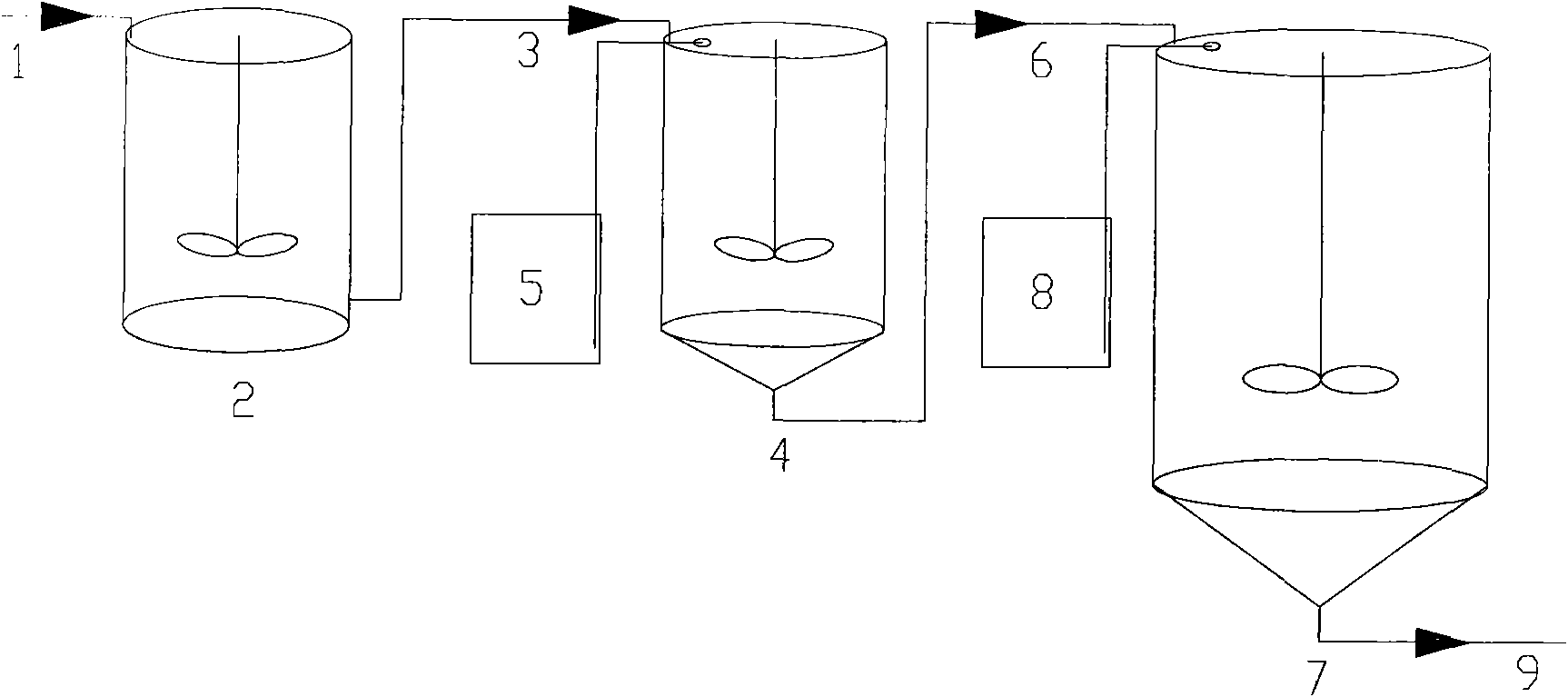

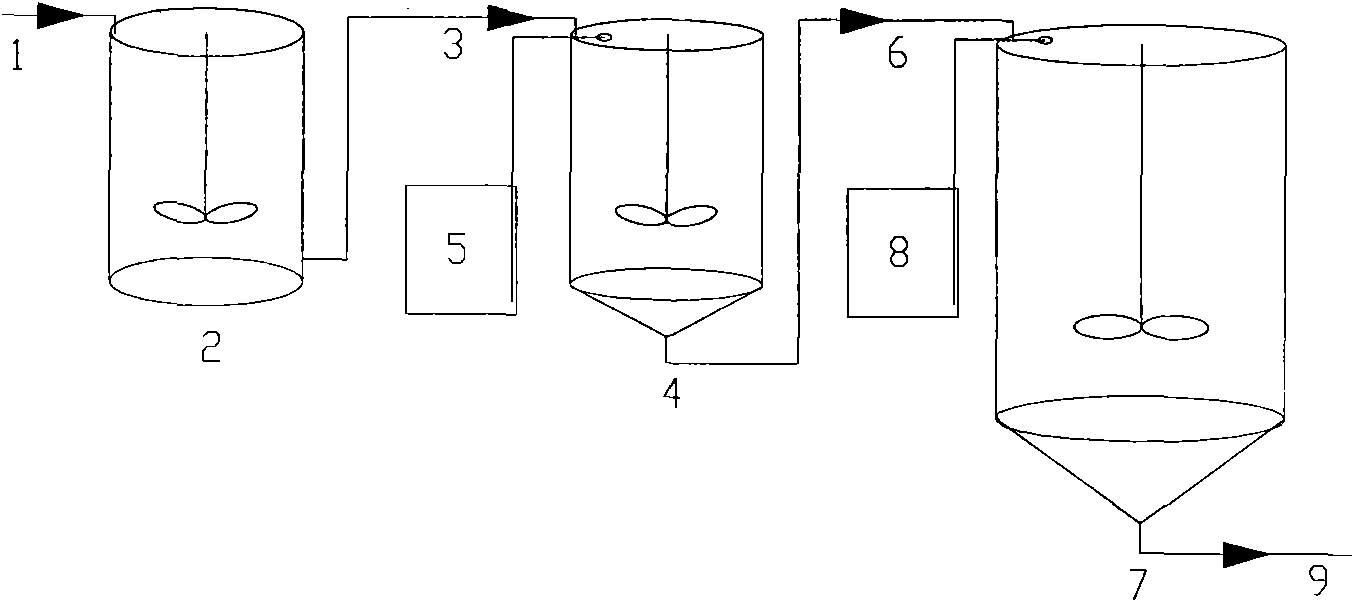

[0021] The remaining sludge of the urban sewage plant first enters the thermal hydrolysis reactor (2) through the sludge inlet pipe (1), and the temperature is controlled between 110°C and 200°C, the pressure is between 600 and 2500kPa, and the reaction time is 15 to 60 minutes. Pretreatment of the excess sludge under certain conditions; the excess sludge after thermal hydrolysis treatment enters the acid-producing phase reactor (4) through the sludge inlet pipe (3), and the temperature of the acid-producing phase is adjusted to 31-36°C or 50°C ~55℃, pH value is 4.5~6.0, redox potential is -300~-100mV, and the substrate concentration, organic load, hydraulic retention time and alkalinity are effectively controlled, and the acid production phase is controlled in the ethanol fermentation stage. Finally, the hydrogen in the product is recovered through the hydrogen collection device (5), and other products enter the closed methanogenic phase reactor through the mud inlet pipe (6) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com