Dimethyl ether preparation technology by utilizing methanol dehydration and special equipment thereof

A dimethyl ether and dimethyl ether rectifying tower technology, which is applied in the dehydration of hydroxyl-containing compounds to prepare ether, ether preparation, organic chemistry, etc., can solve the problems of large technical energy consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

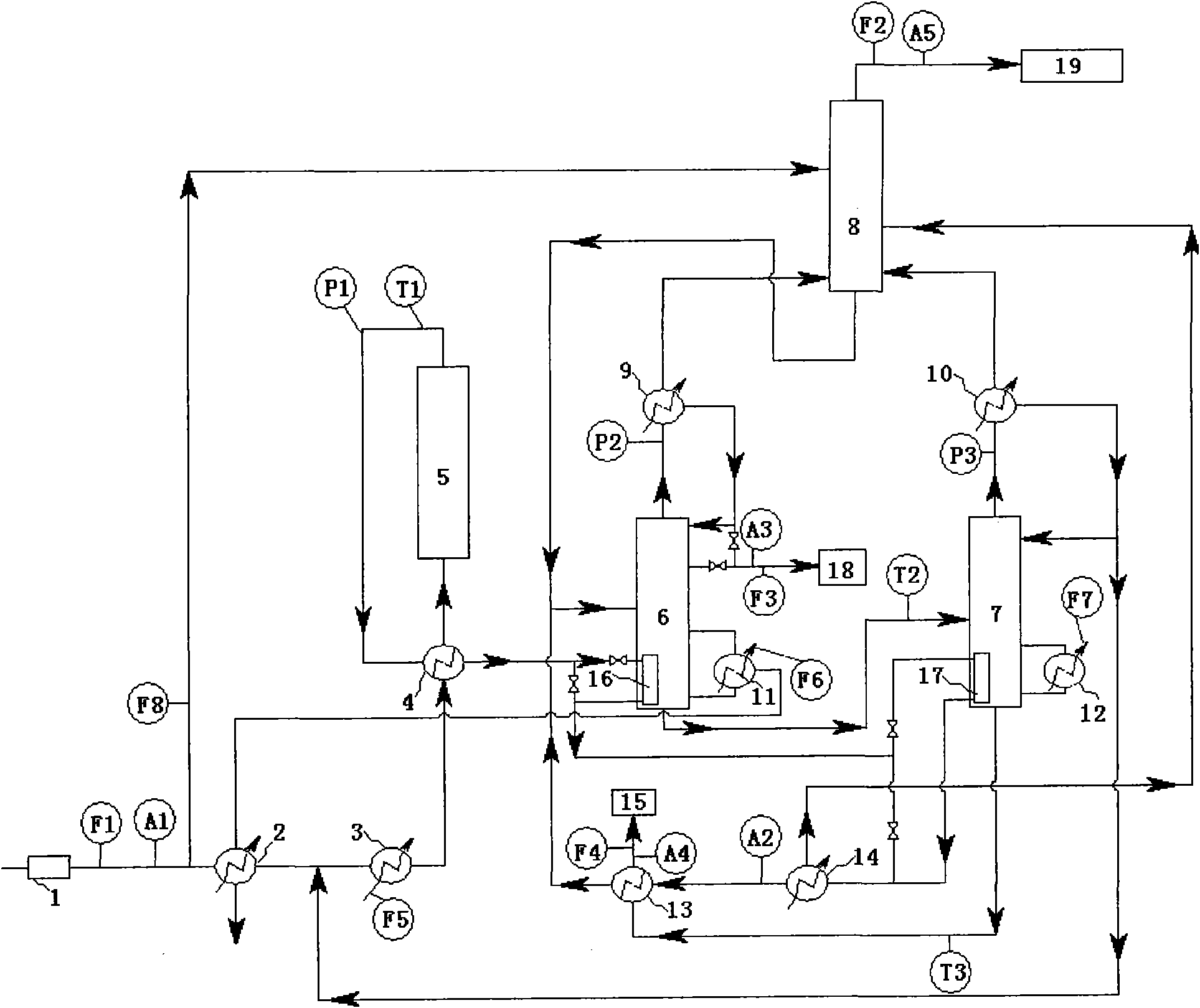

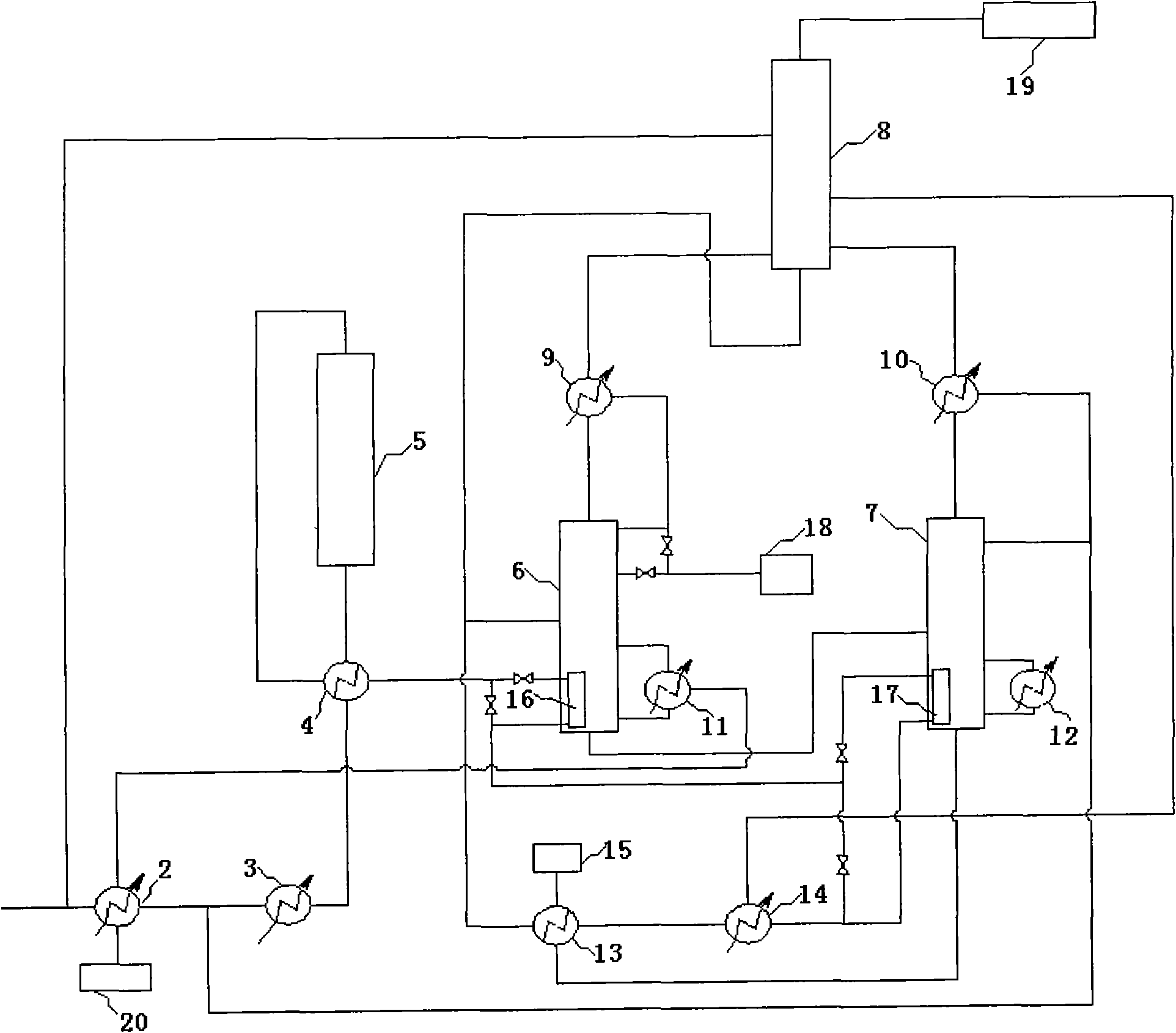

[0056] Refer to attached figure 1 , in combination with the equipment used in the present invention, further more clearly and completely illustrate the process of preparing dimethyl ether from methanol dehydration of the present invention. Except for the specific operating conditions, it is consistent with the following operations: the raw material methanol is passed through the inlet connected to the raw material port. Feed pump 1, then through the first pipeline and the second pipeline split, a part through the first pipeline through the alcohol lotion inlet into the alcohol washing tower 8 as alcohol washing tower alcohol lotion, another part of the liquid methanol through the second pipeline and methanol pre- The cold fluid inlet of the heater 2 enters the methanol preheater 2 for preheating, and comes out of the cold fluid outlet of the methanol preheater 2, then passes through the inlet of the methanol vaporizer 3, enters the methanol vaporizer 3 for vaporization, and is ...

Embodiment 5~7

[0061] When the entire heat exchange network is fully utilized, the process of methanol dehydration to prepare dimethyl ether is carried out. The heat load and parameter data can be seen in Table 2 below.

[0062] Refer to attached figure 1 , its operating steps include: the raw material methanol is passed through the feed pump 1 connected to the raw material port, then through the first pipeline and the second pipeline, and a part is passed through the first pipeline through the alcohol washing agent inlet into the alcohol washing tower 8 as alcohol washing The other part of liquid methanol enters the methanol preheater 2 for preheating through the second pipeline and the cold fluid inlet of the methanol preheater 2, and comes out from the cold fluid outlet of the methanol preheater 2, and then passes through the methanol vaporizer 3 The inlet enters the methanol vaporizer 3 for vaporization, and after vaporization, it comes out from the outlet of the methanol vaporizer 3, an...

Embodiment 8~10

[0065] The heat exchange function of the methanol preheater is canceled, and the process of methanol dehydration to prepare dimethyl ether is carried out while the rest of the heat exchange network is still in use. The heat load and parameter data can be seen in Table 2 below.

[0066]Its operation steps include: passing the raw material methanol through the feed pump 1 connected to the raw material port, and then passing through the first pipeline and the second pipeline to divide the flow, and a part passes through the first pipeline through the alcohol washing agent inlet and enters the alcohol washing tower 8 as the alcohol washing tower Alcohol detergent, another part of liquid methanol passes through the second pipeline, and then enters the methanol vaporizer 3 for vaporization through the inlet of the methanol vaporizer 3. After vaporization, it comes out from the outlet of the methanol vaporizer 3, and then enters the heat exchange from the cold fluid inlet of the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com