Method for preparing self-emulsifying carbon fiber sizing agent component

A self-emulsifying, carbon fiber technology, applied in the direction of carbon fiber, can solve the problems of poor compatibility between emulsifiers and resins, demulsification, and poor compatibility between emulsifiers and epoxy resins, and achieve good sizing effect and compatibility. The effect of good performance and easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of self-emulsifying carbon fiber sizing components.

[0026] In the first step, the epoxy resin E-51 is grafted and modified by emulsion polymerization, and ester groups are introduced into the side chain of the epoxy resin;

[0027] In the second step, the ester group on the side chain is hydrolyzed to obtain a hydroxyl group, and the modified epoxy resin emulsifier with the hydroxyl group and the bisphenol A epoxy resin are prepared through a phase inversion process to prepare a modified epoxy resin emulsion.

[0028] The raw materials used in the emulsion polymerization method are as follows: the epoxy resin adopts epoxy resin E-51, and the emulsifier used in the first step emulsion polymerization adopts polyoxyethylene nonylphenol ether (OP-10), polyoxyethylene dehydrated The composite of sorbitan monooleate (T-80) and sodium dodecylbenzenesulfonate (DBS), the initiator is ammonium persulfate, and the modifier is vinyl acetate.

[0029] Afte...

Embodiment 2

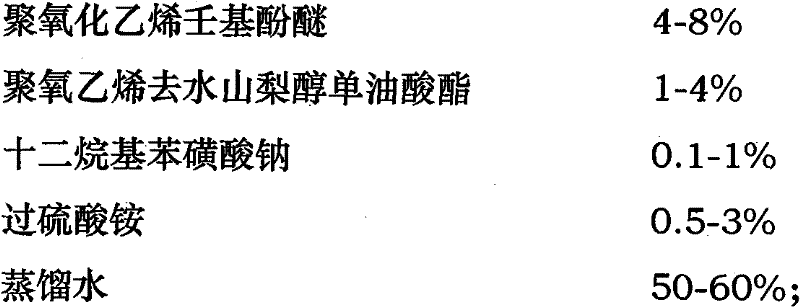

[0053] Select vinyl acetate and epoxy resin E-51 according to the mass ratio of 1:1.5, after the amount of vinyl acetate and epoxy resin E-51 is determined, other components account for the sum of the amount of vinyl acetate and epoxy resin E-51 The weight percent (Wt%) of is:

[0054] Polyoxyethylene nonylphenol ether (OP-10) 6%

[0055] Polyoxyethylene sorbitan monooleate (T-80) 1%

[0056] Sodium dodecylbenzenesulfonate (DBS) 0.5%

[0057] Ammonium persulfate 2%

[0058] Distilled water 60%

[0059] The preparation method is the same as in Example 1, and the solid content of this example is 30%. The prepared sizing agent component is subjected to a performance test, and the results are as follows:

[0060] 1. Increase the stable pH range of the modified epoxy after the second step: 1-14, and the stable pH range of the modified epoxy emulsion after the first step is 4-12;

[0061] 2. Increase the storage period of the modified epoxy emulsion at room temperature after th...

Embodiment 3

[0069] Select vinyl acetate and bisphenol A epoxy resin according to the mass ratio of 1:1. After the amount of vinyl acetate and bisphenol A epoxy resin is determined, other components account for the proportion of vinyl acetate and bisphenol A epoxy resin. The weight percent (Wt%) of consumption sum is:

[0070] Polyoxyethylene nonylphenol ether (OP-10) 4%

[0071] Polyoxyethylene sorbitan monooleate (T-80) 3%

[0072] Sodium dodecylbenzenesulfonate (DBS) 1%

[0073] Ammonium persulfate 0.5%

[0074] Distilled water 50%

[0075] The preparation method is the same as in Example 1, and the solid content of this example is 50%. The prepared sizing agent component is subjected to a performance test, and the results are as follows:

[0076] 1. Increase the stable pH range of the modified epoxy after the second step: 1-14, and the stable pH range of the modified epoxy emulsion after the first step is 6-12;

[0077] 2. Increase the storage period of the modified epoxy emulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com