Controllable synthesis method of nonmetallic ion-doped nano titanium dioxide by phase separation-hydrolysis solvothermal method

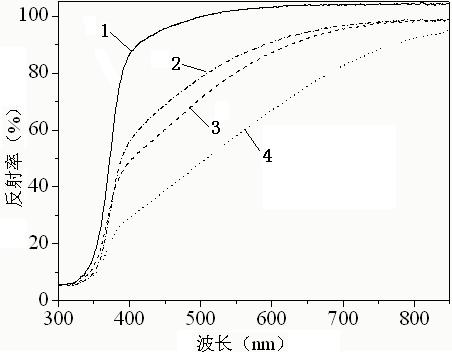

A nano-titanium dioxide, solvothermal technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of low doping efficiency, poor universality, complex process, etc., and achieve strong light absorption. , The effect of low equipment requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

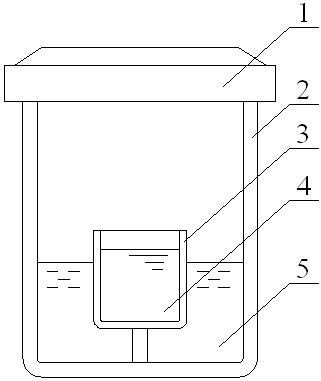

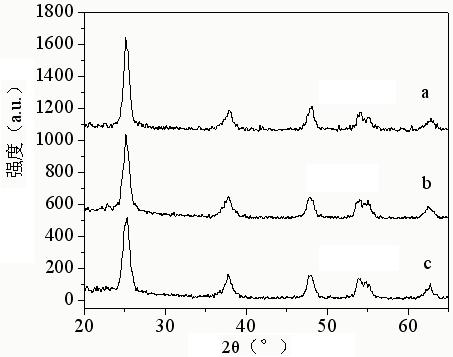

[0007] Specific embodiment 1: In this embodiment, the method for controlling the synthesis of non-metallic ion-doped nano-titanium dioxide by phase separation-hydrolysis solvothermal method is realized according to the following steps: 1. The volume of butyl titanate and toluene is 1:3 Stir for 20-40 minutes after mixing to obtain an organic phase; 2. Add an aqueous solution of non-metal ions with a concentration of 1.5-2.0 mol / L into the autoclave, then put the organic phase into a U-shaped tank and place it in a non-metallic In the aqueous solution of ions (water phase), the liquid level of the aqueous solution of non-metallic ions is located below the top surface of the U-shaped tank, and then the lid is covered, and then solvothermal reaction is performed at 140~180°C for 5~7h, cooled to room temperature, and filtered ; 3. Under the condition of 100~140℃, the precipitate obtained by filtering in step 2 is dried with dimethyl silicone oil bath for 1h, ground, heated to 300~4...

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment is different from Embodiment 1 in that the stirring time described in Step 1 is 30 minutes. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the non-metallic ion aqueous solution described in step 2 is ammonia solution, thiourea solution or sodium sulfide solution. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com