High-performance copper-diamond electrical contact material and preparation process thereof

A technology of electrical contact material and manufacturing process, applied in the direction of contacts, circuits, electrical switches, etc., can solve the problems of composition segregation, reduced wear resistance and welding resistance of electrical contact materials, and poor fixing ability, etc. Achieve the effect of enhancing bonding, improving anti-welding performance and ensuring anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

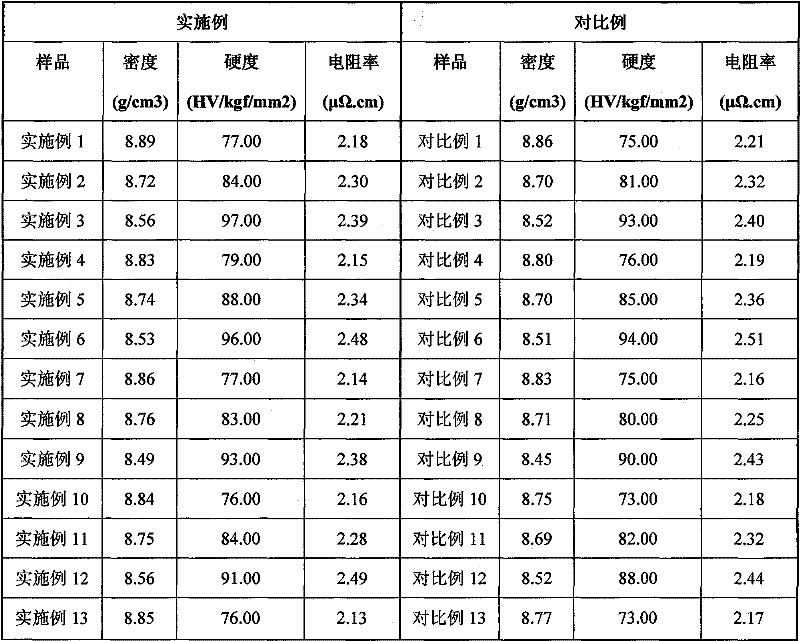

Examples

Embodiment 1

[0030] The composition formula of the high-performance copper-diamond contact material of the present invention is 0.05% of diamond powder (excluding the weight of coated copper) and 99.95% of copper alloy powder by weight percentage.

[0031] The formula of the copper alloy powder is 0.01(mas)% of silver, 0.02(mas)% of nickel, 0.02(mas)% of zirconium and 99.95(mas)% of copper.

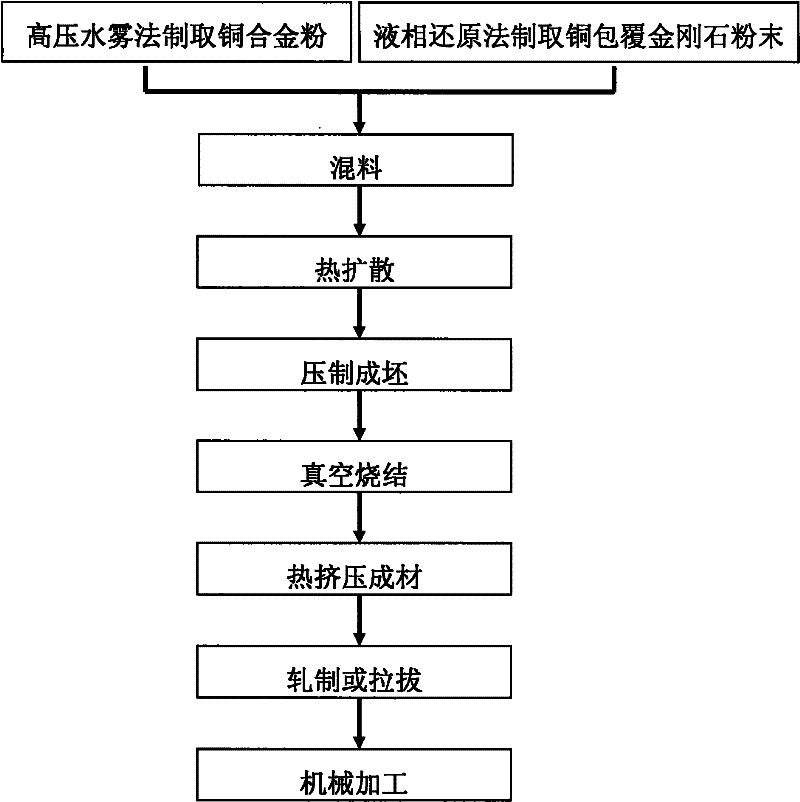

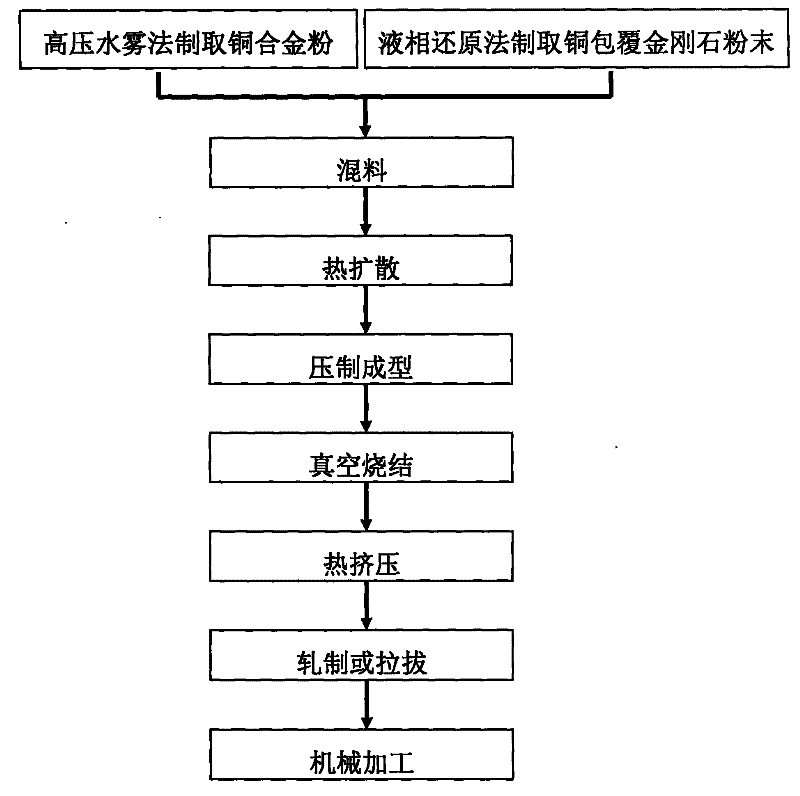

[0032] The manufacturing process of the electrical contact material as shown in Figure 1:

[0033] 1) Preparation of copper alloy powder by high-pressure water atomization method: according to the above-mentioned formula of copper alloy powder, silver, nickel, zirconium and copper metal raw materials are weighed and melted in an intermediate frequency furnace; the melting process is protected by nitrogen, and the temperature is controlled at 1100~1200℃. Then, the copper alloy melt flows through the high-pressure water mist nozzle and is atomized into powder with uniform particle size, the particle si...

Embodiment 2

[0045] The manufacturing process is the same as in Example 1. The composition formula of the high-performance copper-diamond contact material of the present invention is 0.5% of diamond powder (excluding the weight of coated copper) and 99.5% of copper alloy powder by weight percentage.

[0046] The formula of the copper alloy powder is 0.1(mas)% of silver, 0.1(mas)% of nickel, 0.1(mas)% of zirconium and 99.7% of copper.

Embodiment 3

[0048] The manufacturing process is the same as in Example 1. The composition formula of the high-performance copper-diamond contact material of the present invention is 2% of diamond powder (excluding the weight of coated copper) and 98% of copper alloy powder by weight percentage.

[0049] The formula of the copper alloy powder is 1.0(mas)% of silver, 1.0(mas)% of nickel, 1.0(mas)% of zirconium and 97% of copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com