Process for preparing catalysis nano Al2O3 by using starch gel-

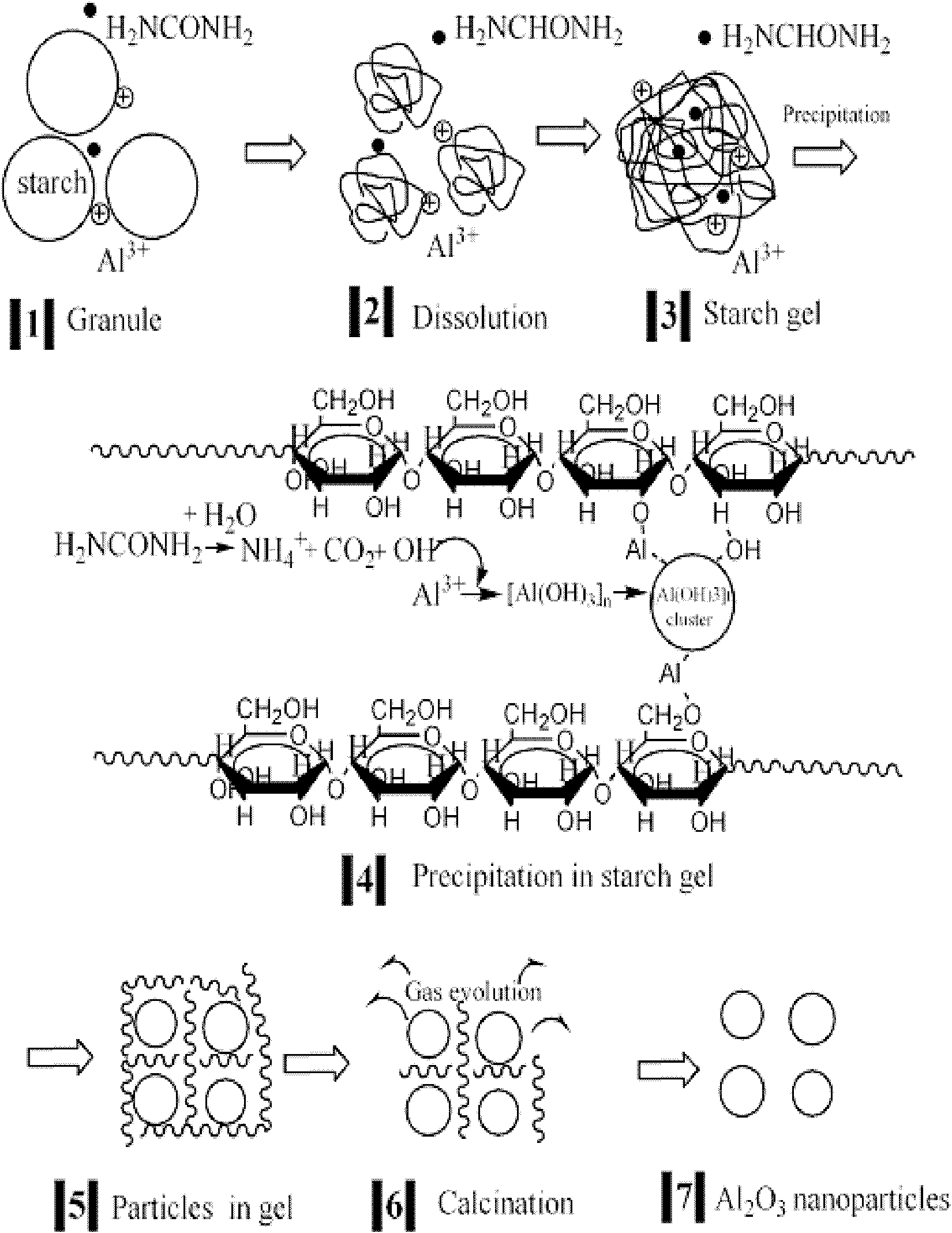

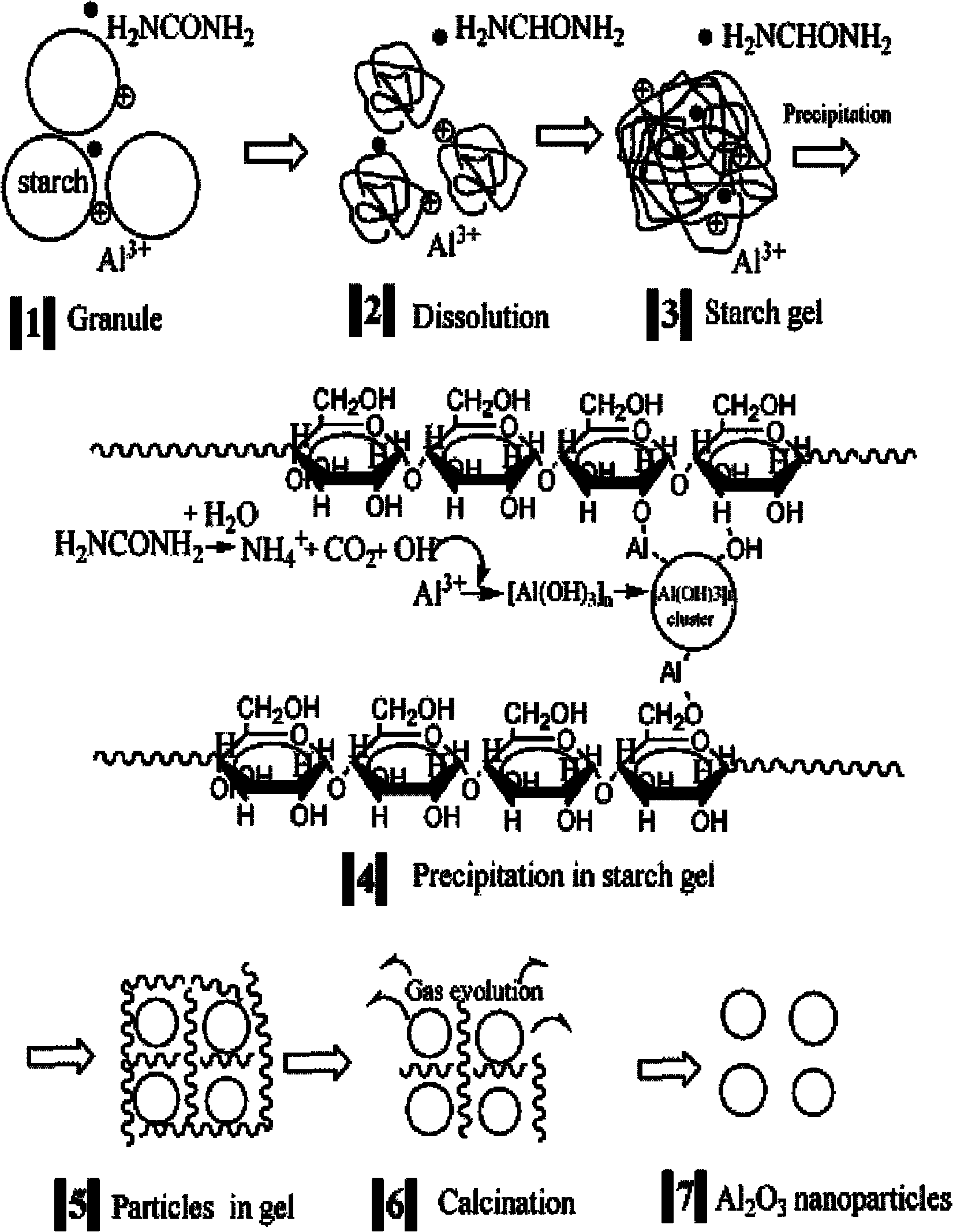

A uniform precipitation and starch technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of particle agglomeration and achieve the effects of avoiding pollution, low cost and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

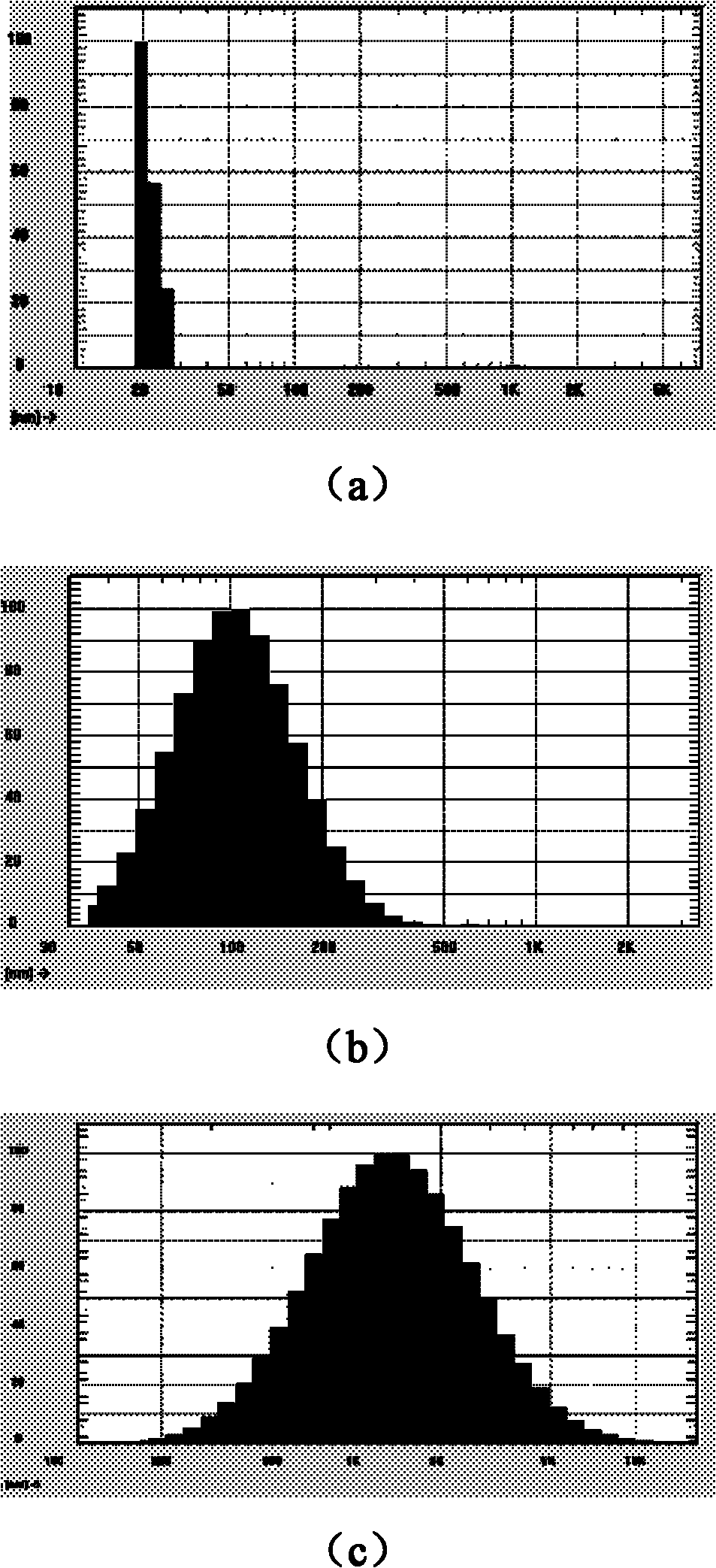

[0035] 3.75g aluminum nitrate Al(NO 3 ) 3 .9H 2 O. Dissolve 5.0g of soluble starch and 1.09g of urea in 100ml of deionized water, heat to 40°C and stir thoroughly, and filter out impurities to form a uniform mixed solution. Take the above mixed solution and heat it to 80°C to gelatinize the starch molecules to form starch gel, and adjust the pH to 3 with 5mol / L ammonia water. The above-mentioned gel was taken out, and the temperature was rapidly increased to 95° C., so that the urea was hydrolyzed and reacted with the inorganic aluminum salt to form a precipitate, and the time was 2 hours. After the above gel was taken and solidified, it was placed in a muffle furnace and calcined at 600°C for 4 hours in an air atmosphere to obtain Al with an average particle size of 18nm. 2 o 3 The powder has a dispersion coefficient of 0.094 and is code-named Gel-Homo-1.

Embodiment 2

[0037] 12.05g aluminum chloride AlCl 3 .6H 2 O (g), 10.0g soluble starch, and 5.45g urea were dissolved in 100ml deionized water, heated to 60°C and stirred thoroughly, and a uniform mixed solution was formed after filtering impurities. Take the above mixed solution and heat it to 85°C to gelatinize the starch molecules to form starch gel, and adjust the pH to 5 with 5mol / L ammonia water. The above-mentioned gel was taken out, and the temperature was rapidly increased to 98° C., so that the urea was hydrolyzed and reacted with the inorganic aluminum salt to form a precipitate, and the time was 5 hours. After the above gel was taken and solidified, it was placed in a muffle furnace and calcined at 550°C for 4 hours in an air atmosphere to obtain Al with an average particle size of 21nm. 2 o 3 The powder has a dispersion coefficient of 0.103 and is code-named Gel-Homo-2.

Embodiment 3

[0039] 60.25g aluminum chloride AlCl 3 .6H 2 O (g), 8.0 g of soluble starch, and 22.4 g of urea were dissolved in 100 ml of deionized water, heated to 60° C., stirred thoroughly, and then filtered to remove insoluble impurities to form a mixed solution. Take the above mixed solution and heat it to 85°C to gelatinize the starch molecules to form starch gel, and adjust the pH to 7 with 5mol / L ammonia water. The above-mentioned gel was taken out, and the temperature was rapidly increased to 98° C., so that urea was hydrolyzed and reacted with inorganic aluminum salt to form a precipitate, and the time was 8 hours. After the above gel was taken and solidified, it was placed in a muffle furnace and calcined at 600°C for 12 hours in an air atmosphere to obtain Al with an average particle size of 43nm. 2 o 3 The powder has a dispersion coefficient of 0.162 and is code-named Gel-Homo-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com