Magnesium alloy anticorrosion coating and preparation method thereof

A technology for anti-corrosion coatings and magnesium alloys, applied in the directions of anti-corrosion coatings, polyamide coatings, epoxy resin coatings, etc., to achieve the effects of high corrosion resistance, high practicability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Backup epoxy resin, polyamide, magnesium powder (average particle size 10 microns, purity 99%), defoamer BYK-A530 and titanate coupling agent according to the following mass percentages: 24% , 24%, 50%, 0.5% and 1.5%;

[0024] 2) epoxy resin is dissolved in the solvent that xylene and n-butanol are mixed by mass ratio 7: 3, is mixed with the mass fraction of epoxy resin and is the solution of 62.5%; Polyamide is dissolved in xylene and n-butanol In the solvent mixed in a mass ratio of 7:3, the mass fraction of polyamide prepared into a solution is 62.5%;

[0025] 3) After mixing the magnesium powder with the epoxy resin solution prepared in step 2), add a titanate coupling agent, stir evenly, and then add the polyamide solution prepared in step 2) and the defoamer BYK-A530, After dispersing for 5 minutes, aging for 5 minutes to obtain the magnesium alloy anti-corrosion coating.

Embodiment 2

[0027] 1) Backup epoxy resin, polyamide, magnesium powder (average particle size 30 microns, purity 99%), defoamer BYK-A530 and titanate coupling agent according to the following mass percentages: 22% , 22%, 55%, 0.5% and 0.5%;

[0028] 2) with step 2) in embodiment 1;

[0029] 3) Same as step 3) in Example 1.

Embodiment 3

[0031] 1) Back up epoxy resin, polyamide, magnesium powder (average particle size 60 microns, purity 99%), defoamer BYK-A530 and titanate coupling agent according to the following mass percentages: 19.25% , 19.25%, 60%, 0.5% and 1%;

[0032] 2) with step 2) in embodiment 1;

[0033] 3) Same as step 3) in Example 1.

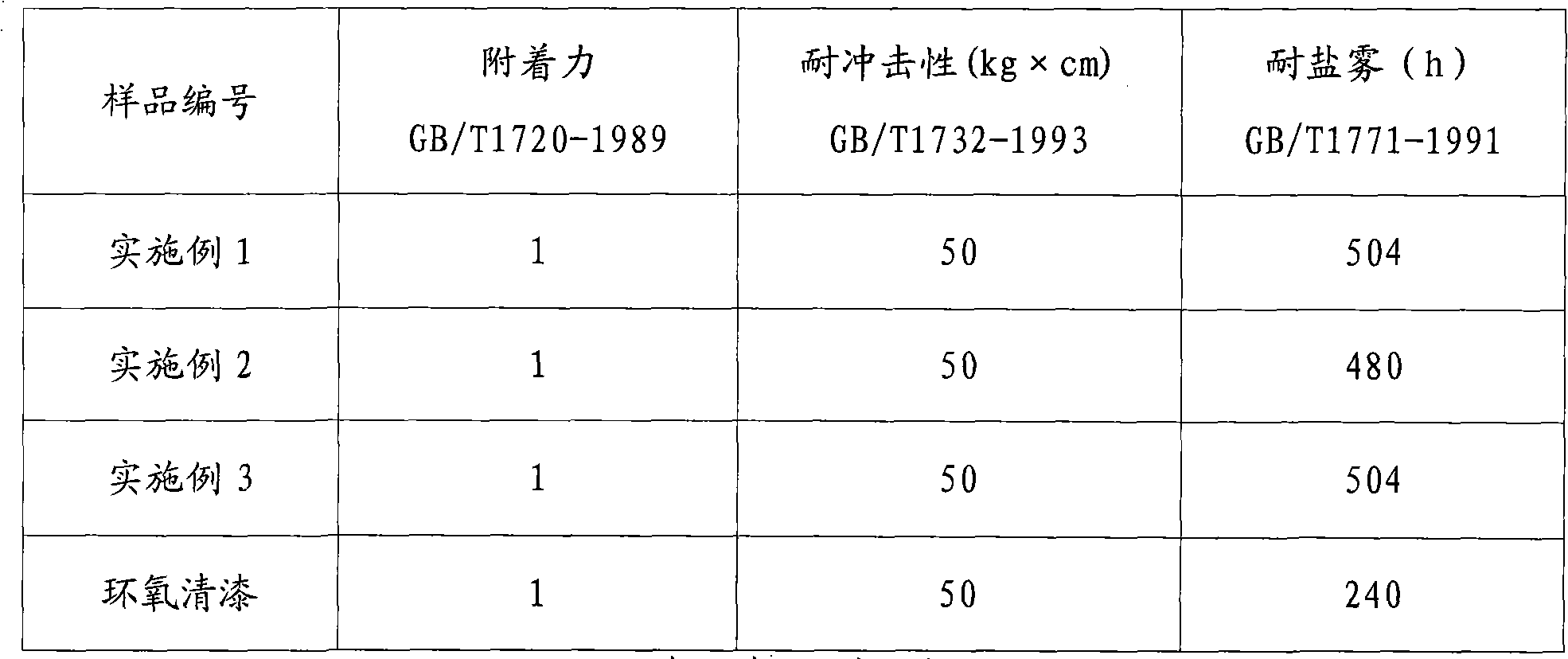

[0034] Table 1 shows the performance evaluation results of the magnesium alloy anti-corrosion coatings prepared in Examples 1-3. All tests are carried out according to national standards. The salt spray test adopts the scratch method (GB / T1771-1991), and the evaluation standard is scratch Pitting or bubbling begins to appear at the marks. As can be seen from the table, the adhesion and impact strength of the magnesium alloy anti-corrosion paint prepared by the present invention are similar to those of ordinary epoxy varnishes, while its salt spray resistance is greatly improved compared with ordinary epoxy varnishes. All the test pieces installed can pass the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com