Method for synthesizing La-Mg hydrogen storage alloy by microwave aid heating

A hydrogen storage alloy, microwave-assisted technology, applied in microwave heating and other directions, can solve the problems of difficulty in large-scale production, long time-consuming, time-consuming process, etc., and achieves the promotion of endothermic and exothermic reactions, favorable thermodynamic conditions, and high heating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

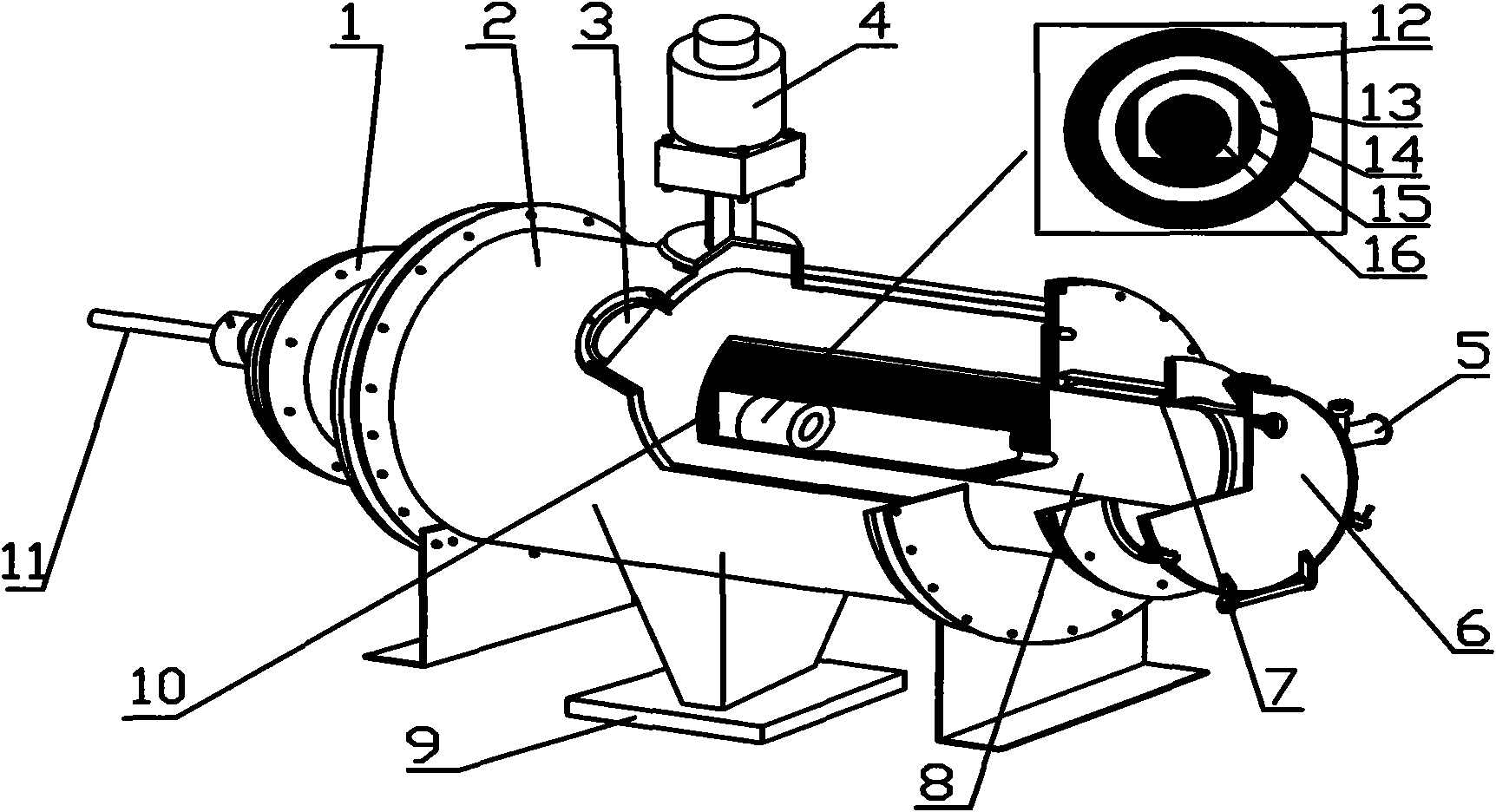

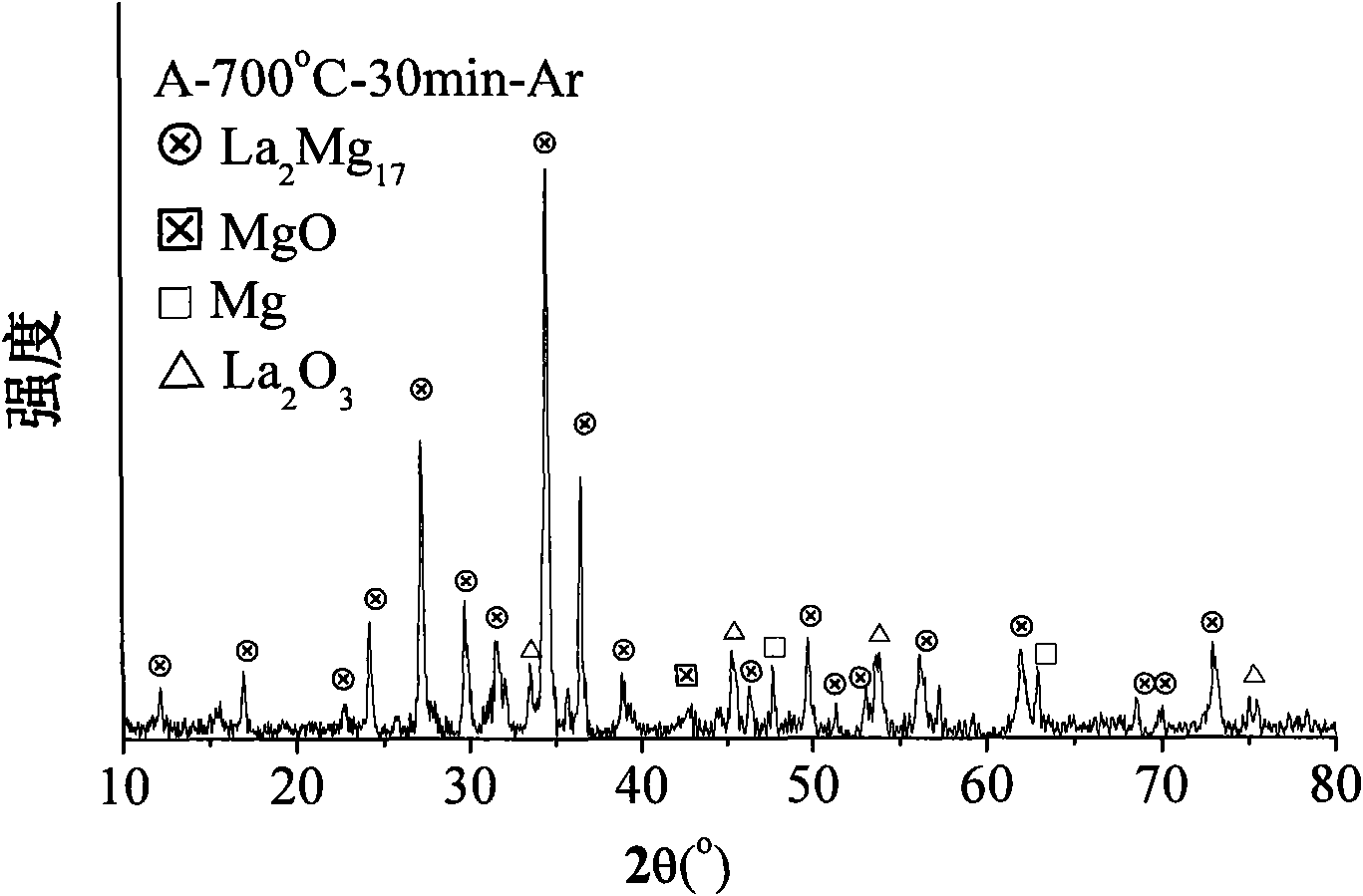

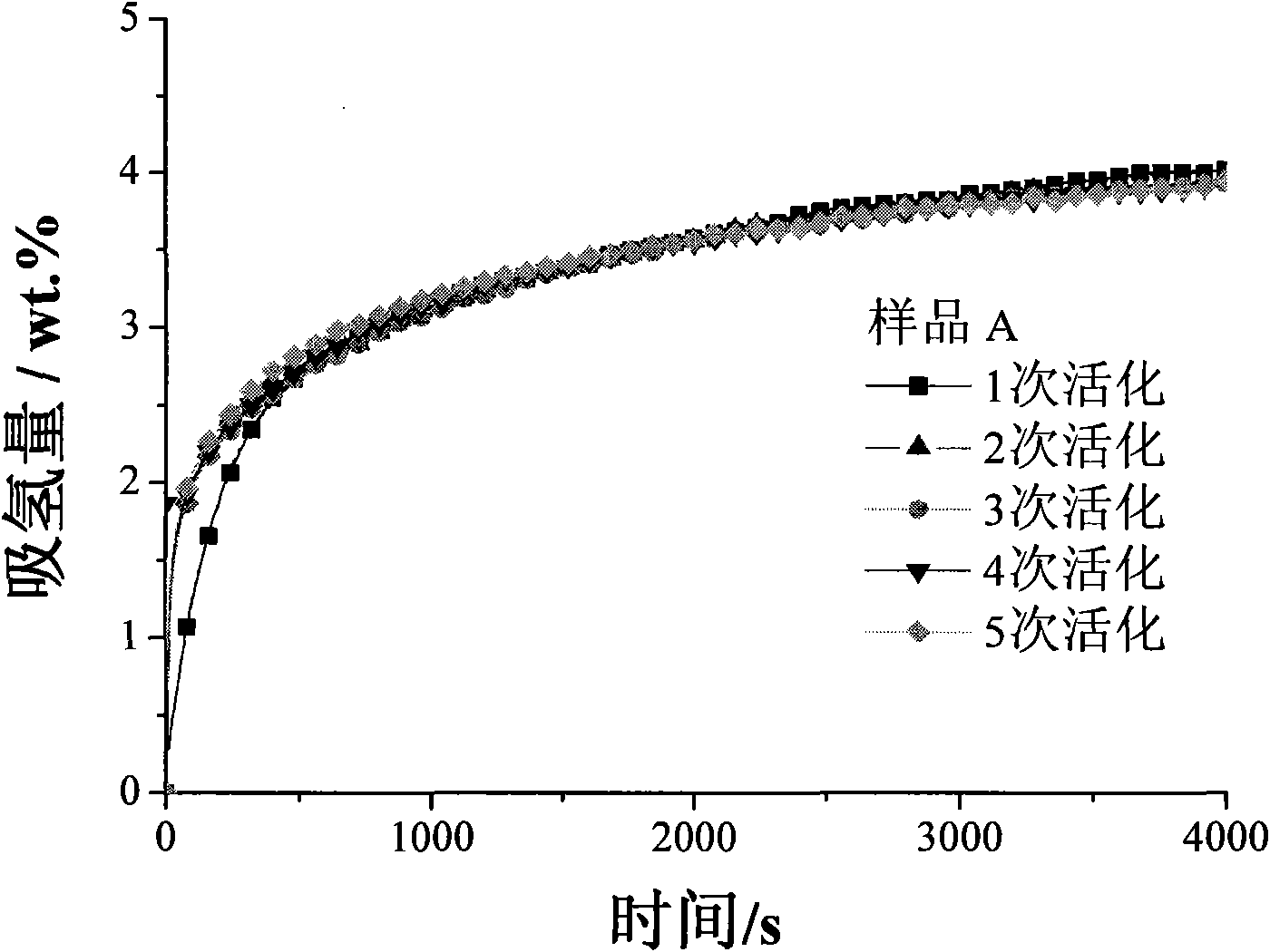

[0023] Embodiment 1: take by weighing lanthanum powder (purity 99.83%, particle diameter 100 meshes), magnesium powder (purity 99.9%, particle diameter 200 meshes) by weighing by stoichiometric ratio 1: 8.5 and mix, place QF-1sp type planetary type simultaneously Mix thoroughly in a ball mill. In order to prevent oxidation during the ball milling process, the samples in the ball milling tank were carried out in a glove box. The volume of the ball mill jar used is 80cm 3 , the ball-to-material ratio is 10:1 (using 150g grinding balls / 15g powder), and the rotating speed of the main shaft during ball milling is 200 rpm. After mixing well, keep the pressure under the pressure of 450MPa for 2min, and compress into tablets (Φ15×2mm discs) on a 769YP-24B powder tablet press. The tableted sample is placed in a microwave tube furnace, and argon gas with a purity ≥ 99.999% is introduced for protection after vacuuming. Turn on the microwave power supply, raise the temperature of the s...

Embodiment 2

[0025] Weigh lanthanum powder (purity 99.83%, particle size 100 mesh) and magnesium powder (purity 99.9%, particle size 200 mesh) according to the stoichiometric ratio of 1:8.5 and mix them, and place them in a QF-1sp planetary ball mill for full mixing . In order to prevent oxidation during the ball milling process, the samples in the ball milling tank were carried out in a glove box. The volume of the ball mill jar used is 80cm 3 , the ball-to-material ratio is 10:1 (using 150g grinding balls / 15g powder), and the rotating speed of the main shaft during ball milling is 200 rpm. After mixing well, keep the pressure under the pressure of 450MPa for 2min, and compress into tablets (Φ15×2mm discs) on a 769YP-24B powder tablet press. The pressed sample was placed in a microwave tube furnace, and after vacuuming, a furnace containing 5at% H 2 A mixture of hydrogen and argon for protection. Turn on the microwave power supply, raise the temperature of the sample to 680°C at a hea...

Embodiment 3

[0027]Weigh lanthanum powder (purity 99.83%, particle size 100 mesh) and magnesium powder (purity 99.9%, particle size 100 mesh) according to the stoichiometric ratio of 1:12, mix them, and place them in a QF-1sp planetary ball mill for full mixing . In order to prevent oxidation during the ball milling process, the samples in the ball milling tank were carried out in a glove box. The volume of the ball mill jar used is 80cm 3 , the ball-to-material ratio is 10:1 (using 150g grinding balls / 15g powder), and the rotating speed of the main shaft during ball milling is 200 rpm. After mixing well, keep the pressure under the pressure of 450MPa for 2min, and compress into tablets (Φ15×2mm discs) on a 769YP-24B powder tablet press. The tableted sample is placed in a microwave tube furnace, and argon gas with a purity ≥ 99.999% is introduced for protection after vacuuming. Turn on the microwave power supply, raise the temperature of the sample to 680°C at a heating rate of 30°C / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com