Biological antibiotic cotton fibers or cotton cloth and method for preparing same

A technology of antibacterial fiber and biological antibacterial agent, which is applied in the field of biological antibacterial cotton fiber or cotton cloth and its preparation, can solve the problems of antibacterial fiber safety and poor washing resistance, and achieve non-toxic side effects, low cost, and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The preparation steps of this antibacterial cotton cloth or antibacterial fiber are as follows:

[0013] (1) Preparation of oxidized cellulose

[0014] Put cotton cloth or cotton fiber in a three-necked flask equipped with agitator and thermometer, add sodium periodate solution with a concentration of 0.03-0.1mol / L, and oxidize at 30-60°C for 2-6 hours under dark conditions to obtain the active The oxidized cotton fiber of the group is reacted with 0.1-1.0% glycerin, washed for 0.5-2 hours, and then fully washed with distilled water to remove glycerin. Put the oxidized cotton cloth fibers in the air to dry naturally or at high temperature.

[0015] (2) Grafting of oxidized cellulose and ε-PL

[0016] The dried oxidized cellulose is placed in 0.5-5% ε-polylysine aqueous solution and reacted at room temperature. After the reaction is completed, take it out and dry it or dry it in the air to obtain antibacterial cotton fiber or cotton cloth.

[0017] (3) It is also pos...

Embodiment 1

[0019] Weigh 3g of pure cotton fiber, put it in a three-necked flask equipped with a stirring and thermometer, add a 0.04mol / L sodium periodate solution, and oxidize it at 30°C for 4 hours under dark conditions to obtain an oxidized cotton cloth containing active groups Fiber, oxidized cotton cloth fiber was reacted with 0.1% glycerin, washed for 0.5h, and then fully washed with distilled water to remove glycerin. Put the oxidized cotton cloth fibers in the air to dry naturally or at high temperature. The dried oxidized cellulose was placed in 1.0% ε-polylysine aqueous solution and reacted at room temperature for 3 hours. After the reaction was completed, it was taken out and dried or air-dried to obtain antibacterial cotton fibers.

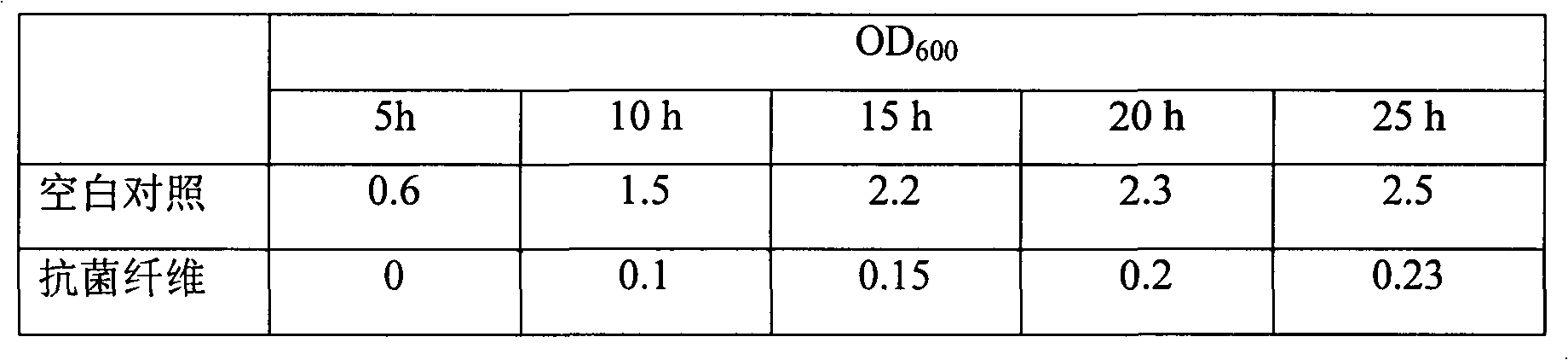

[0020] The antibacterial performance test was carried out on the prepared antibacterial cotton fiber. 0.3mL of Escherichia coli in the logarithmic phase was connected to 50mL of sterilized LB liquid medium, and 0.15g of the treated antibacterial ...

Embodiment 2

[0024] Weigh 3g of pure cotton cloth, place it in a three-necked flask equipped with a stirring and thermometer, add a 0.06mol / L sodium periodate solution, and oxidize it at 30°C for 3 hours in the dark to obtain an oxidized cotton cloth containing active groups Fiber, oxidized cotton cloth fiber was reacted with 0.1% glycerin, washed for 0.5h, and then fully washed with distilled water to remove glycerin. Arrange the oxidized cotton in the air to dry naturally or at high temperature. Arrange the dried oxidized cotton in 1.0% ε-polylysine aqueous solution and react at room temperature for 3 hours. After the reaction is completed, take it out and dry it or dry it in the air to obtain an antibacterial cotton cloth.

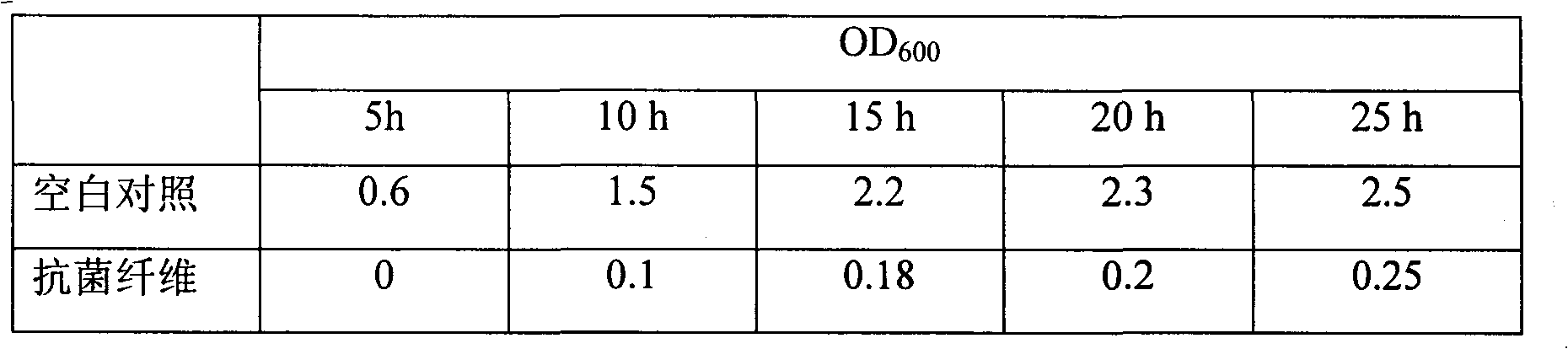

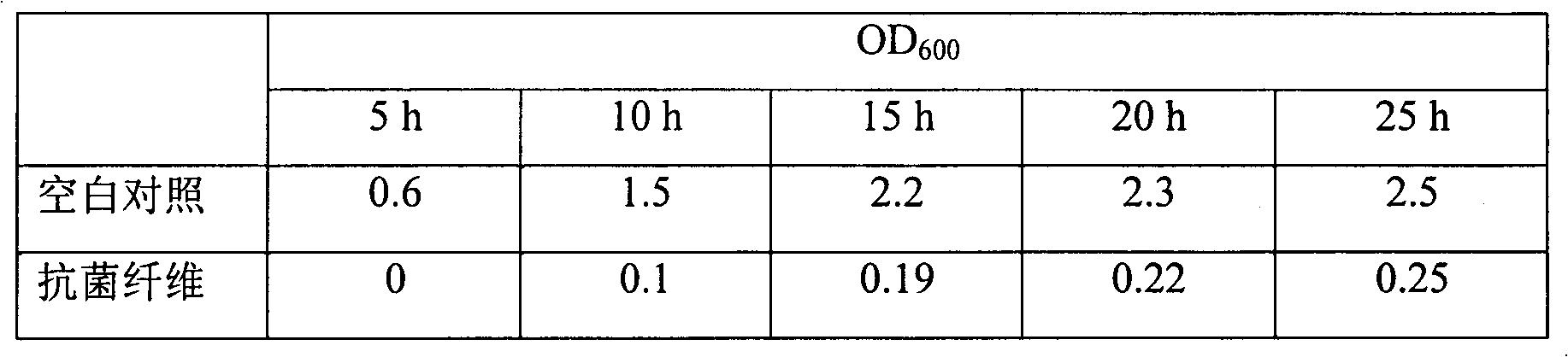

[0025] The antibacterial performance test was carried out on the prepared antibacterial cloth. 0.3mL of Escherichia coli in the logarithmic phase was connected to 50mL of sterilized LB liquid medium, and 0.15g of the treated antibacterial cloth was also connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com