Piperacillin sodium-tazobactam sodium medicinal composition microsphere injection

A technology of tazobactam sodium and piperacillin sodium, which is applied in the field of medicine and can solve problems such as large burst release, difficulty in large-scale preparation, and poor process reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

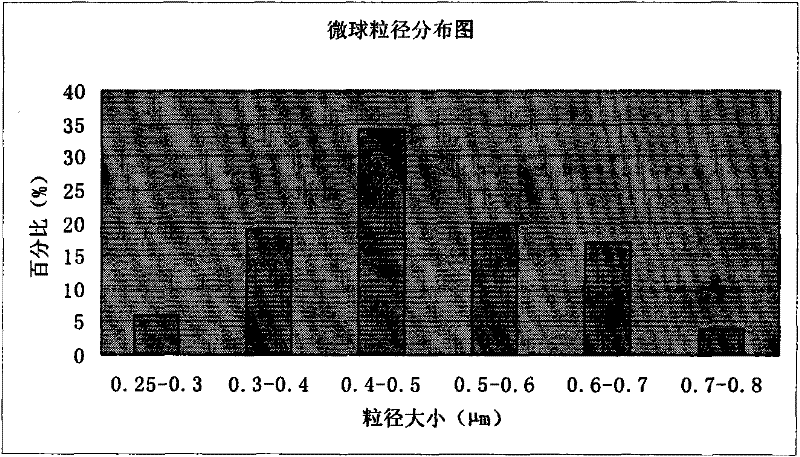

Embodiment 1

[0073] Example 1 Preparation of microsphere injection of pharmaceutical composition of piperacillin sodium and tazobactam sodium

[0074] Prescription: (100 bottles)

[0075] Piperacillin Sodium 40g

[0076] Tazobactam Sodium 10g

[0077] PLA-PEG 40g

[0078] PEG600 60g

[0079] Polysorbate 80 10g

[0080] Mannitol 20g

[0081] Preparation Process:

[0082] (1) Dissolve 40g piperacillin sodium, 10g tazobactam sodium, 60gPEG600 and 20g mannitol in 800ml water for injection to obtain an aqueous phase;

[0083] (2) Dissolve 40g PLA-PEG and 10g polysorbate 80 in 200ml dichloromethane to obtain an oil phase;

[0084] (3) Slowly drip the water phase obtained above into the oil phase under stirring conditions, stir for 10 minutes after dripping, and then transfer to a high-speed homogenizer and stir at high speed for 3 times, each time for 10 minutes, to obtain a uniform white emulsion ;

[0085] (4) Put the white emulsion into the spray dryer, adjust the spray conditions (inlet temperature 65°C, ou...

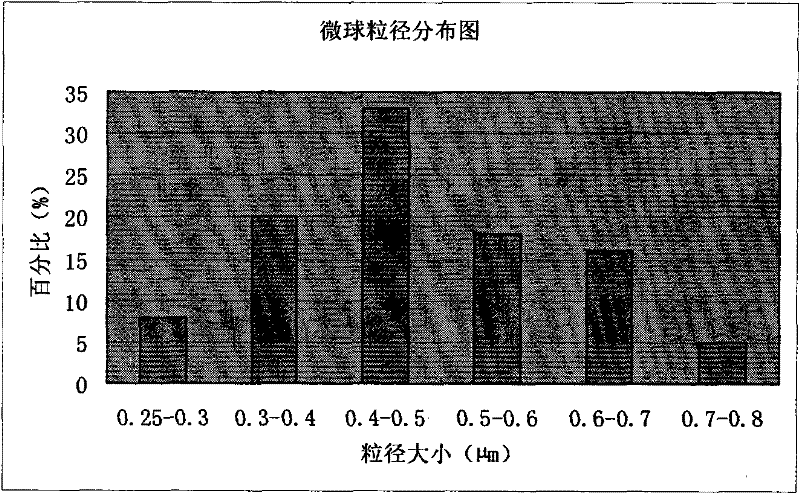

Embodiment 2

[0101] Example 2 Preparation of microsphere injection of pharmaceutical composition of piperacillin sodium and tazobactam sodium

[0102] Prescription: (100 bottles)

[0103] Piperacillin Sodium 80g

[0104] Tazobactam Sodium 10g

[0105] PLA-PEG 55g

[0106] PEG600 70g

[0107] Polysorbate 80 15g

[0108] Mannitol 20g

[0109] Preparation Process:

[0110] (1) Dissolve 80g piperacillin sodium, 10g tazobactam sodium, 70gPEG600 and 20g mannitol in 1000ml water for injection to obtain an aqueous phase;

[0111] (2) Dissolve 55g PLA-PEG and 15g Polysorbate 80 in 300ml of toluene to obtain an oil phase;

[0112] (3) Slowly drip the water phase obtained above into the oil phase under stirring conditions, stir for 10 minutes after dripping, and then transfer to a high-speed homogenizer and stir at high speed for 3 times, each time for 10 minutes, to obtain a uniform white emulsion ;

[0113] (4) Put the white emulsion into the spray dryer, adjust the spray conditions (inlet temperature 70°C, outlet...

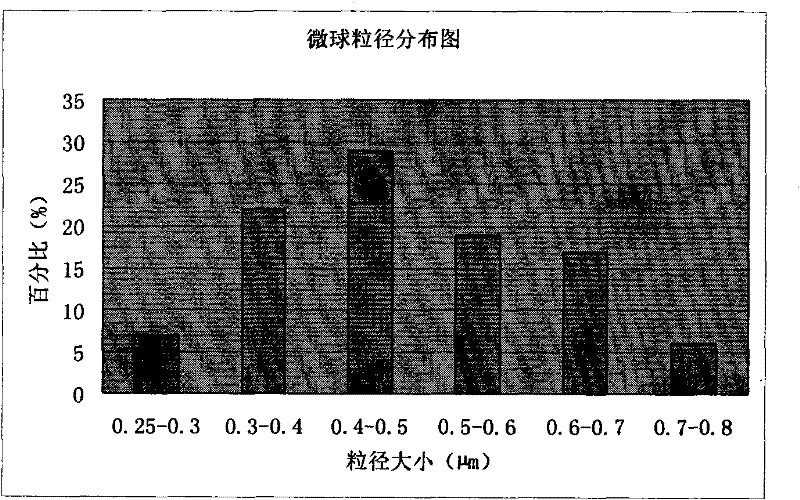

Embodiment 3

[0129] Example 3 Preparation of microsphere injection of pharmaceutical composition of piperacillin sodium and tazobactam sodium

[0130] Prescription: (100 bottles)

[0131] Piperacillin Sodium 80g

[0132] Tazobactam Sodium 10g

[0133] PLA-PEG 60g

[0134] PEG600 65g

[0135] Polysorbate 80 22g

[0136] Mannitol 30g

[0137] Preparation Process:

[0138] (1) Dissolve 80g piperacillin sodium, 10g tazobactam sodium, 65gPEG600 and 30g mannitol in 1200ml water for injection to obtain an aqueous phase;

[0139] (2) Dissolve 60g PLA-PEG and 22g polysorbate 80 in 400ml acetone to obtain an oil phase;

[0140] (3) Slowly drip the water phase obtained above into the oil phase under stirring conditions, stir for 10 minutes after dripping, and then transfer to a high-speed homogenizer and stir at high speed for 5 times, each time for 10 minutes, to obtain a uniform white emulsion ;

[0141] (4) Put the white emulsion into the spray dryer, adjust the spray conditions (inlet temperature 75°C, outlet te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com