Method for preparing nano active carbon spheres by using blue-green algae residue

A technology of activated carbon spheres and cyanobacteria algae dregs, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of infeasibility and high cost, and achieve simple operation, elimination of hazards and pollution, and stable product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method for preparing nano-activated carbon spheres by using cyanobacteria algae dregs:

[0022] 1. Collect algal residues, including air-floated algal residues, coagulated algal residues or artificially salvaged algal residues;

[0023] 2. Air-dry the algae dregs naturally or at 50-100 degrees until the water content is 5-10%, crush them into powder, and pass through a 150-200 mesh sieve;

[0024] 3. Mix the algae residue powder and phosphoric acid with a mass concentration of 40-60% in a mass ratio of 1:2.5, and soak for 2-10 hours;

[0025] 4. Put the soaked mixture into a muffle furnace for carbonization at 300-500°C for 60-120 minutes, then cool it down to room temperature naturally;

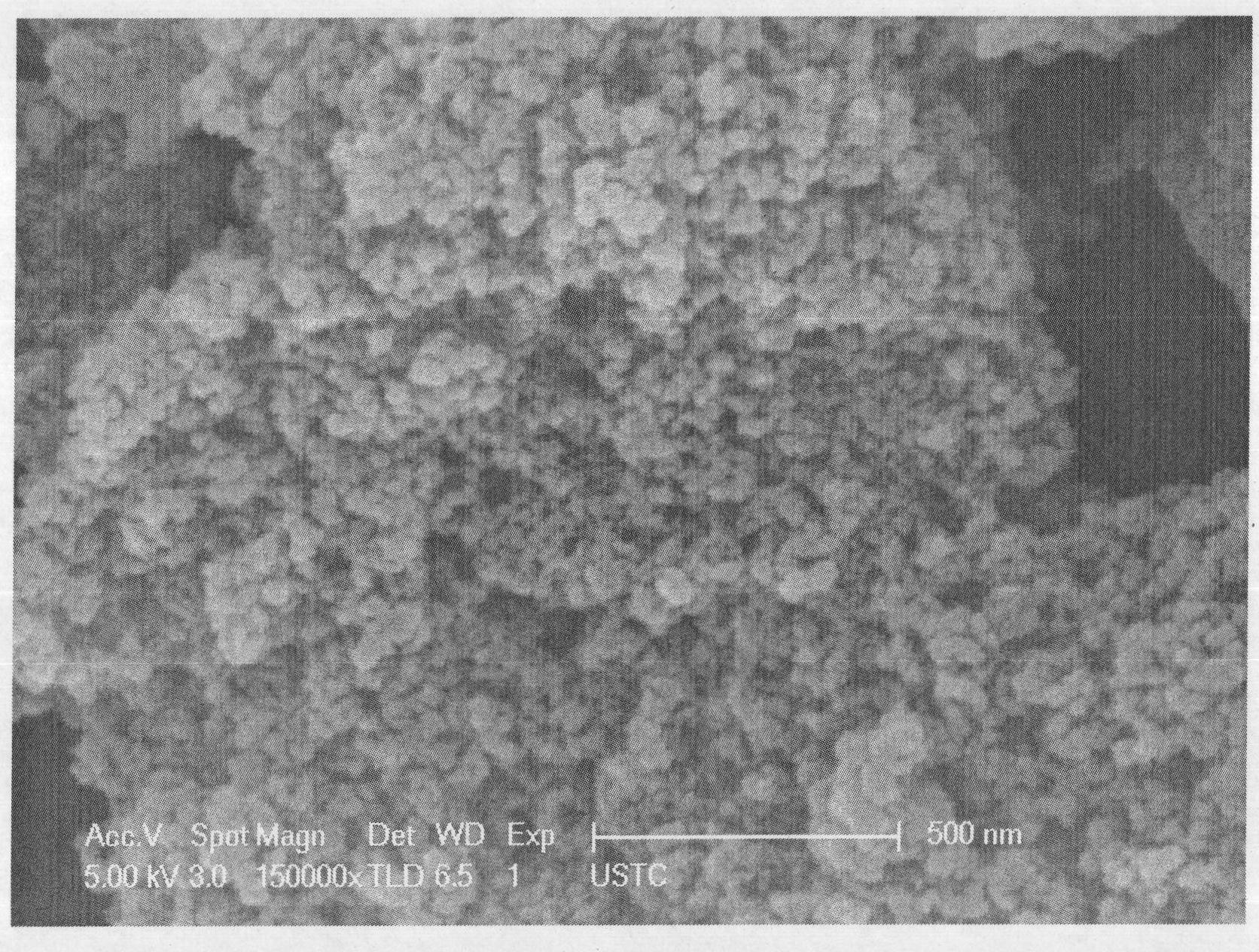

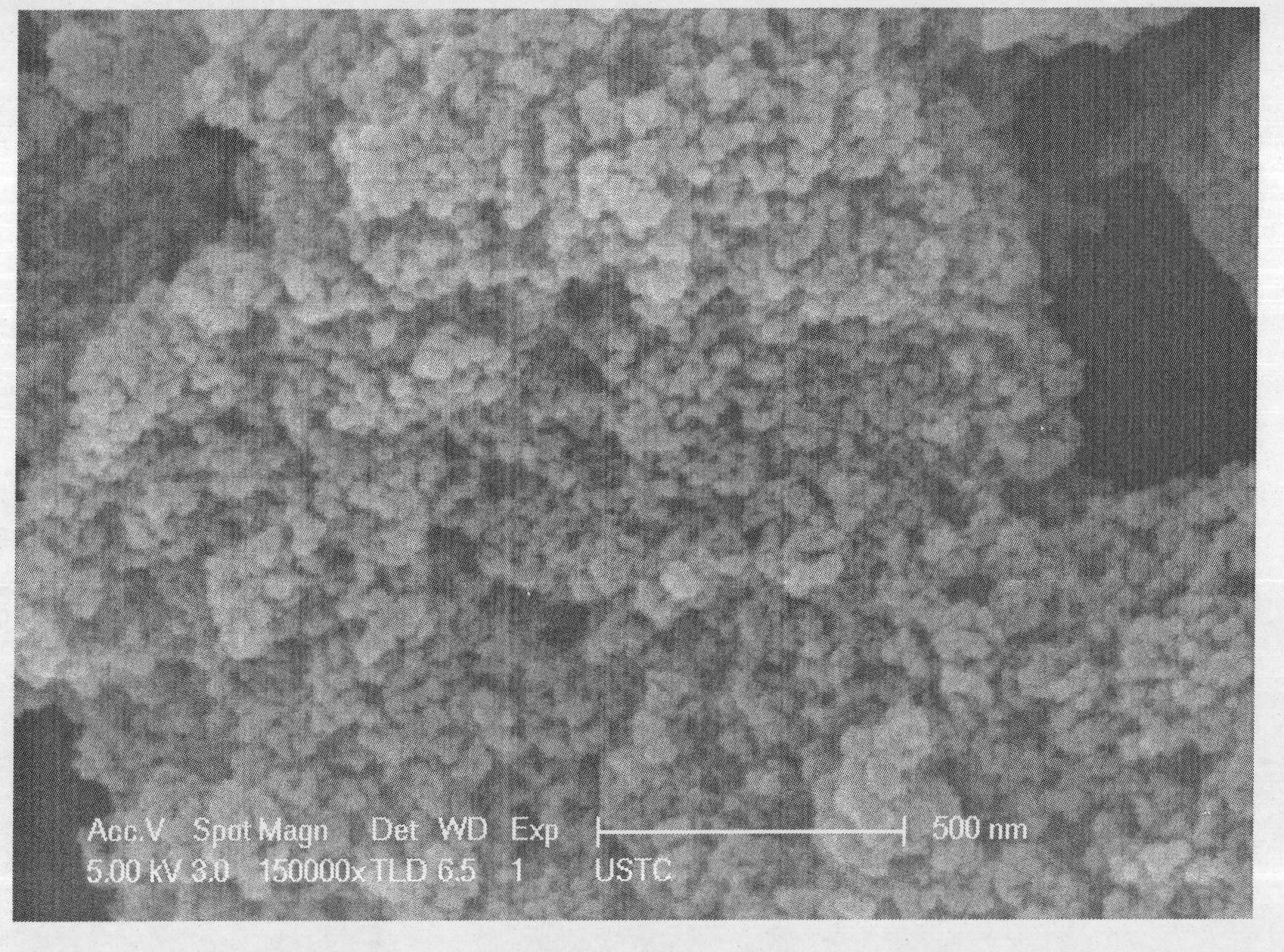

[0026] 5. Wash the carbonized algae residue with 1mol / L hydrochloric acid, deionized water, and absolute ethanol three times in sequence, then dry at 20-60°C, grind, and pass through a 200-mesh sieve to obtain a uniform diameter of 5-10nm. Activated carbon balls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com