Method for preparing Mg-Ti-ZrO2 catalytic material

One - mg-ti-zro2, the technology of catalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem that the reactor is easily corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

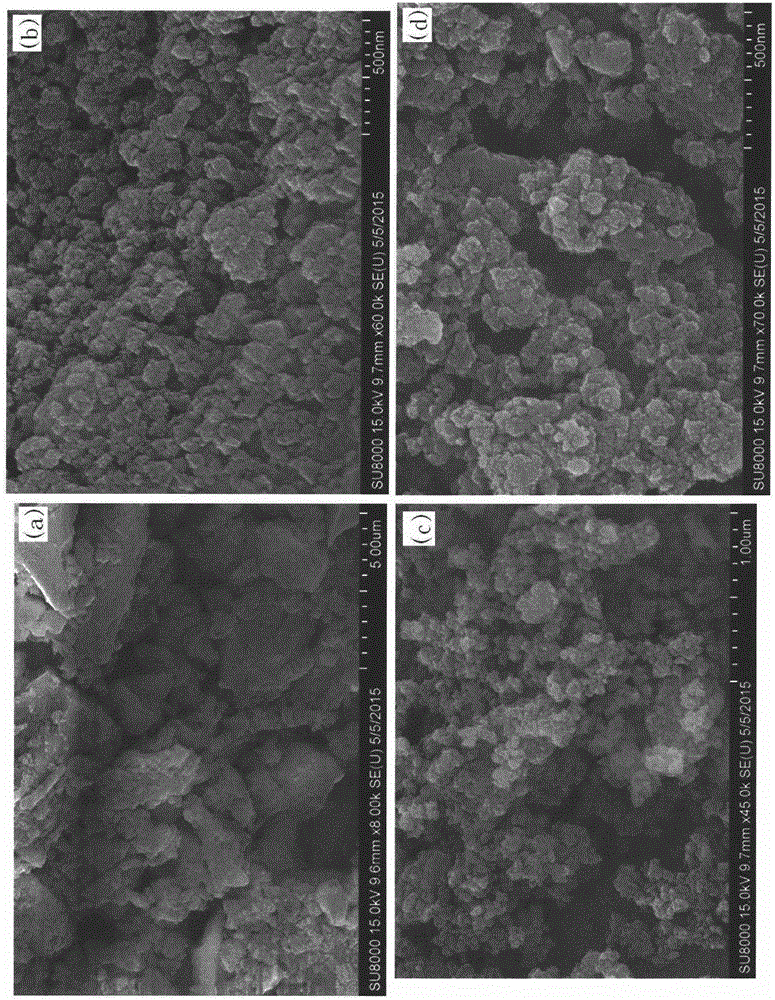

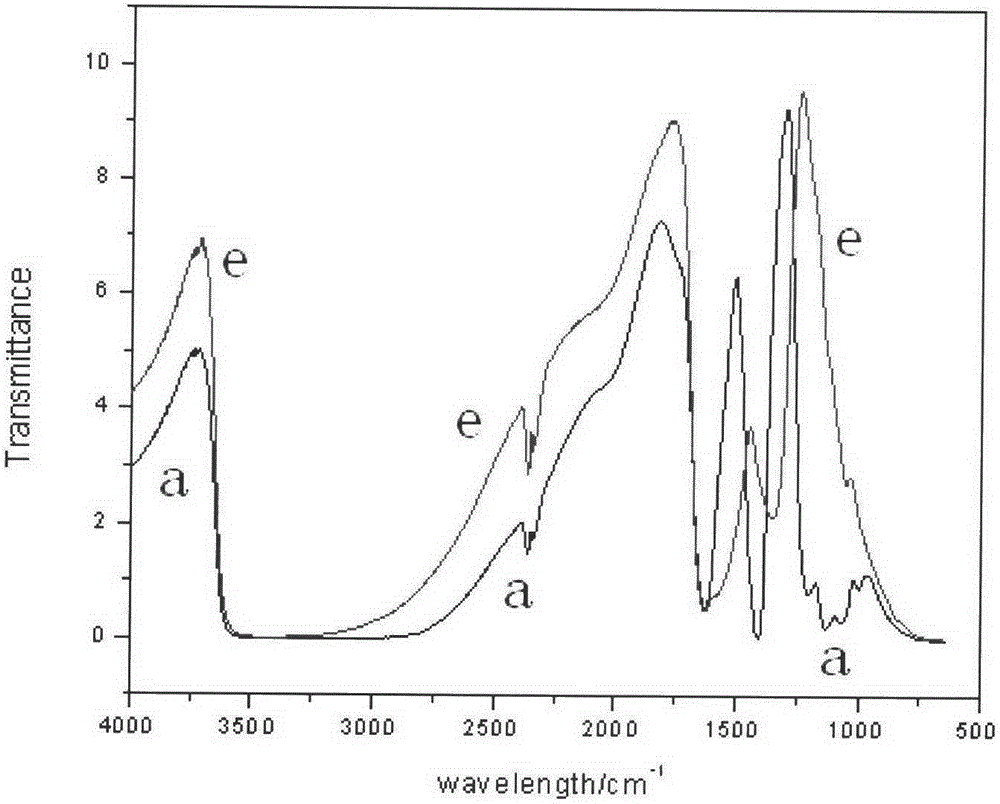

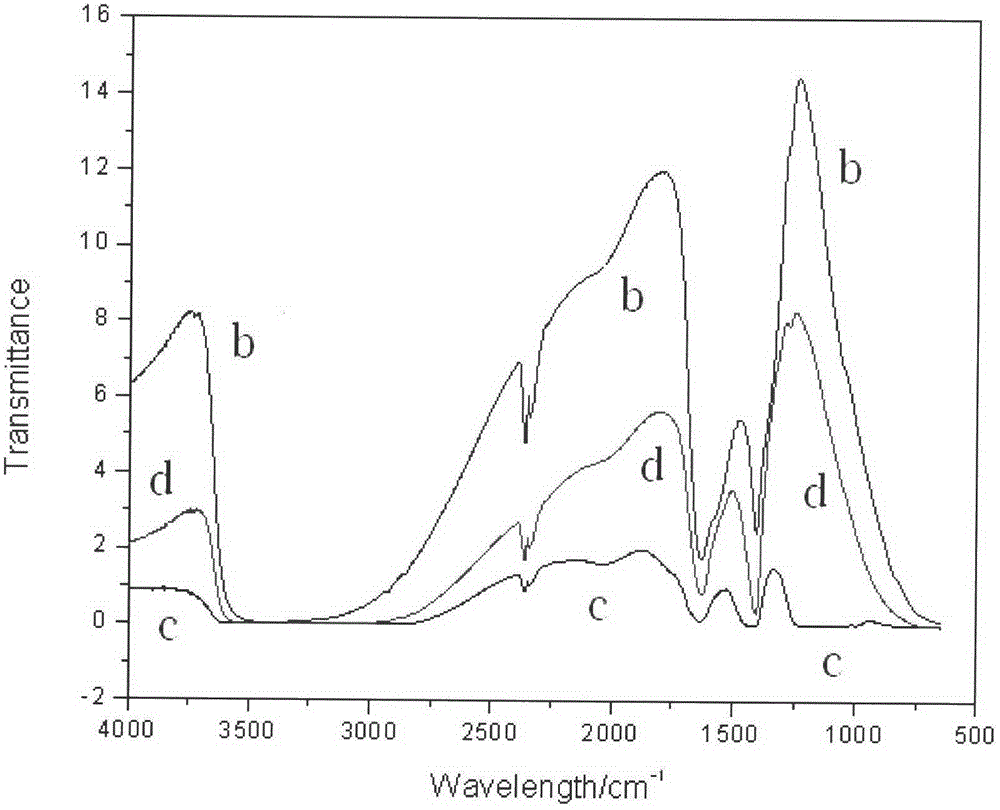

Image

Examples

Embodiment 1

[0025] Mg-Ti-Ce-ZrO 2 Preparation of catalytic materials:

[0026] ①. Weigh 9.6675g of ZrOCl 2 ·8H 2 O, 1.0000g of C 19 h 42 BrN, 0.3578 g of MgCl 2 ·6H 2 O, 0.2715g of TiCl 3 and 0.7116g of Ce(SO 4 ) 2 4H 2 O into the beaker.

[0027] ② Measure 2.5mL of concentrated ammonia water, add distilled water to dilute to 100mL, take out 50mL of diluted ammonia water and pour it into a beaker, add a few drops of absolute ethanol dropwise, add dilute ammonia water dropwise while stirring with a glass rod, until the solution Stop dropping when the pH value is around 8.

[0028] ③. Put the magnet into the beaker, wrap the beaker with plastic wrap to prevent the solution from being oxidized when it is exposed to the air for a long time, and stir for two hours with a magnetic stirrer.

[0029] ④. Pour the stirred solution into the reaction kettle, then put the reaction kettle in the oven, set the temperature at 80°C, carry out the hydrothermal reaction, and take it out after 24...

Embodiment 2

[0034] Mg-Ti-ZrO 2 Preparation of catalytic materials:

[0035] ①. Weigh 9.6675g of ZrOCl 2 ·8H 2 O, 1.0000g of C 19 h 42 BrN, 0.5367g of MgCl 2 ·6H 2 O and 0.4072g TiCl 3 Put in a beaker.

[0036] ② Measure 2.5mL of concentrated ammonia water, add distilled water to dilute to 100mL, take out 50mL of diluted ammonia water and pour it into a beaker, add a few drops of absolute ethanol dropwise, and add dilute ammonia water dropwise while stirring with a glass rod until the solution reaches Stop dropping when the pH value is around 8.

[0037] ③ Put the magnet into the beaker, wrap the beaker with plastic wrap to prevent the solution from being oxidized when exposed to the air for a long time, and stir for two hours with a magnetic stirrer.

[0038] ④. Pour the stirred solution into the reaction kettle, then put the reaction kettle in the oven, set the temperature at 80°C, carry out the hydrothermal reaction, and take it out after 24 hours.

[0039] ⑤. After the temper...

Embodiment 3

[0043] Mg-Ce-ZrO 2 Preparation of catalytic materials:

[0044] ①. Weigh 9.6675g of ZrOCl 2 ·8H 2 O, 1.0000g of C 19 h 42 BrN, 0.5367g of MgCl 2 ·6H 2 O and 1.0674g of Ce(SO 4 ) 2 4H 2 O into the beaker.

[0045] ② Measure 2.5mL of concentrated ammonia water, add distilled water to dilute to 100mL, take out 50mL of diluted ammonia water and pour it into a beaker, add a few drops of absolute ethanol dropwise, and add dilute ammonia water dropwise while stirring with a glass rod until the solution reaches Stop dropping when the pH value is around 8.

[0046] ③ Put the magnet into the beaker, wrap the beaker with plastic wrap to prevent the solution from being oxidized when exposed to the air for a long time, and stir for two hours with a magnetic stirrer.

[0047] ④. Pour the stirred solution into the reaction kettle, then put the reaction kettle in the oven, set the temperature at 80°C, carry out the hydrothermal reaction, and take it out after 24 hours.

[0048] ⑤. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com