Polycarboxylic acid type special additive for lightweight aggregate concrete

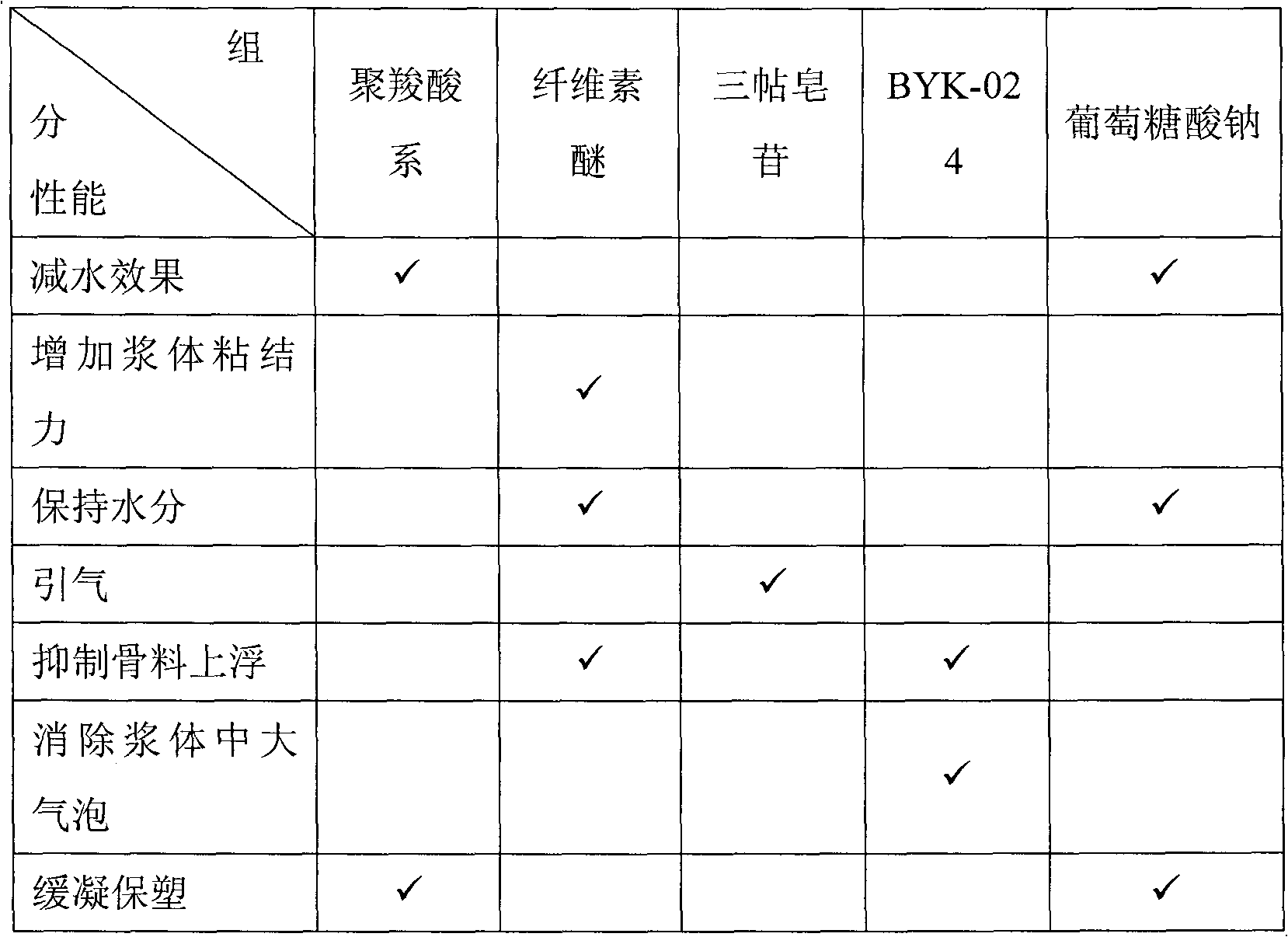

A lightweight aggregate concrete and polycarboxylic acid-based technology, which is used in the field of special admixtures for concrete and polycarboxylic acid-based admixtures for lightweight aggregate concrete, can solve the problem that the homogeneity and plastic preservation properties of concrete are not significantly improved, It is difficult to accurately control the degree of pre-wetting of lightweight aggregate, and the effect of lightweight aggregate concrete is not good, which can achieve obvious economic and social benefits, improve construction work efficiency, and increase slump loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

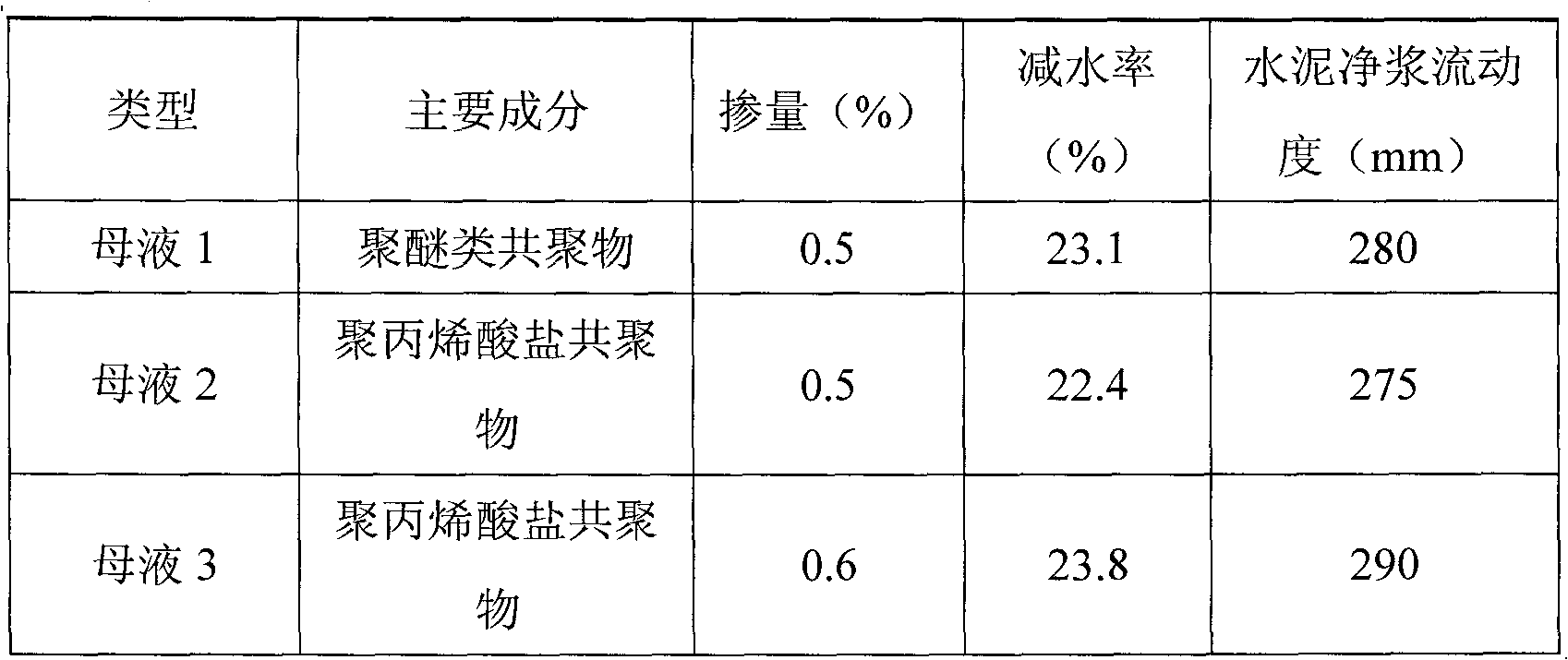

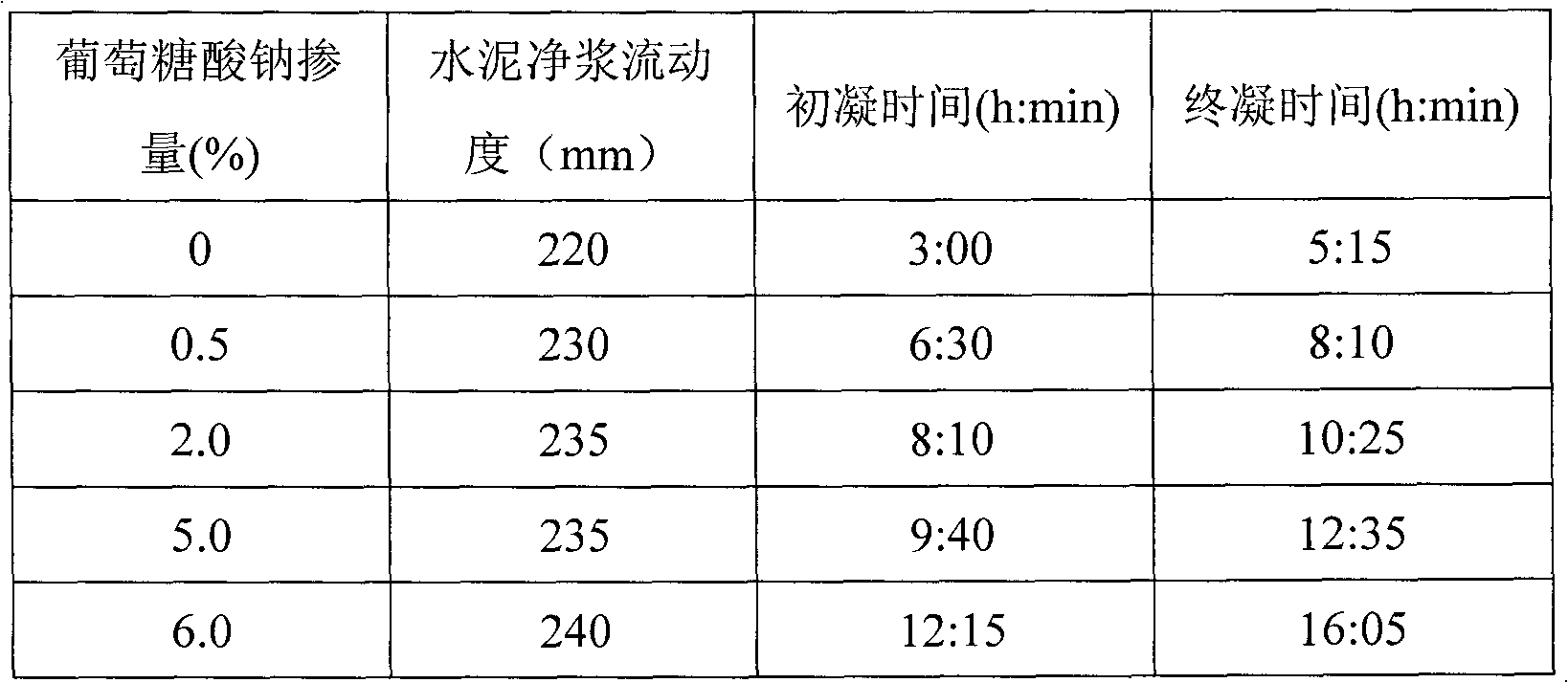

[0053] A special polycarboxylate admixture for lightweight aggregate concrete, consisting of 400g of polycarboxylate water reducer, 30g of commercially available industrial grade sodium gluconate, 1g of tripartite saponin, 1g of defoaming component BYK-024, hydroxypropyl Prepared by adding 0.05 g of methyl cellulose ether into 568 g of water and stirring for about 90 seconds. The polycarboxylic acid-based water reducer is a polymethacrylic acid copolymer whose side chain is polyoxyethylene, and the water reducing rate is above 20%; the viscosity of the hydroxypropyl methyl cellulose ether is 12000-18000mP· s; the defoaming component BYK-024 is polysiloxane and its composite product with a specific surface area lower than 16-21Mn / m.

[0054] When using, first weigh 1% of the amount of concrete cementitious material, first mix the sand, gravel, cement, and mineral admixtures in the concrete for 1 minute, then add water and admixture while stirring, and stir for more than 2 minut...

example 2

[0063] A special admixture for lightweight aggregate concrete polycarboxylate, consisting of 800g of polycarboxylate water reducer, 40g of commercially available industrial grade sodium gluconate, 2g of tripartite saponin, 1.5g of defoaming component BYK-024, and Prepared by adding 0.1 g of hydroxyethyl cellulose ether into 1157 g of water and stirring for about 90 seconds. The polycarboxylate water reducer is a polyether copolymer whose side chain is polyoxyethylene, and the water reducing rate is above 20%; the viscosity of methyl hydroxyethyl cellulose ether is 12000-18000mP·S; the said The defoaming component BYK-024 is polysiloxane and its compound product with a specific surface area lower than 16-21Mn / m.

[0064] When using, first do a test on the optimum dosage of the admixture to determine the appropriate dosage of the admixture. First mix the sand, gravel, cement, and mineral admixtures in the concrete for 1 minute, then add water and admixtures while stirring, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com