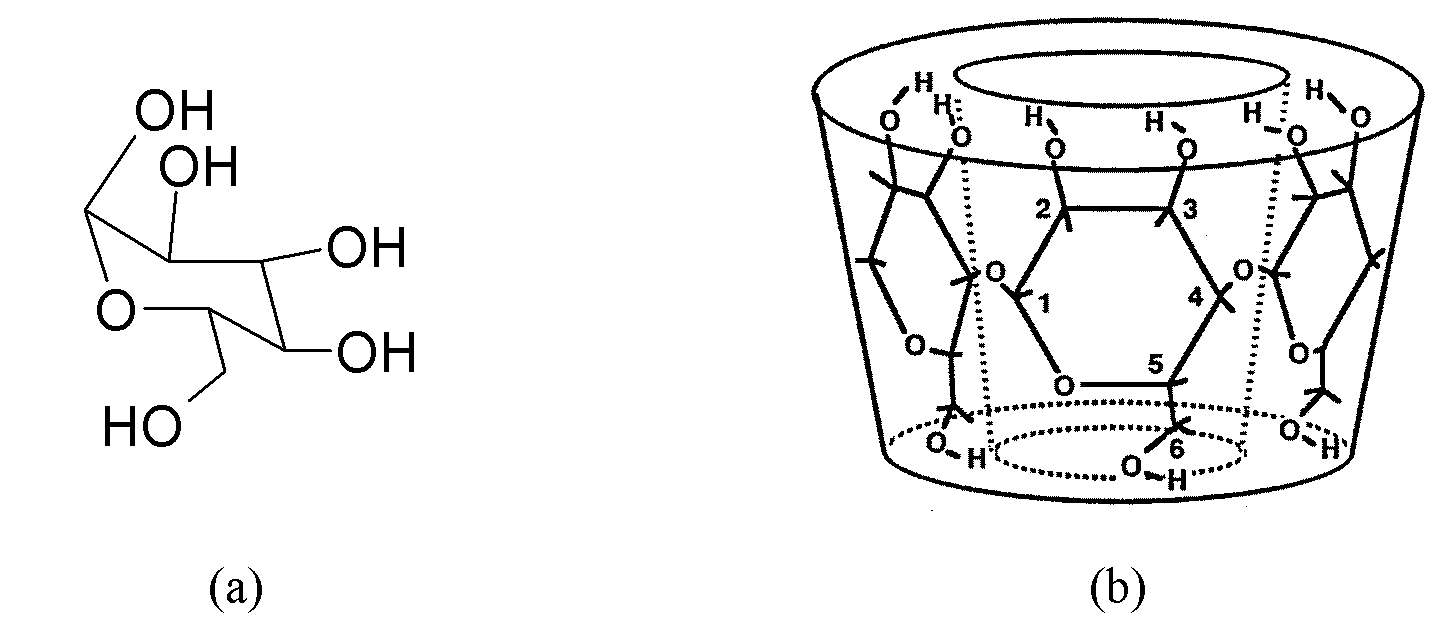

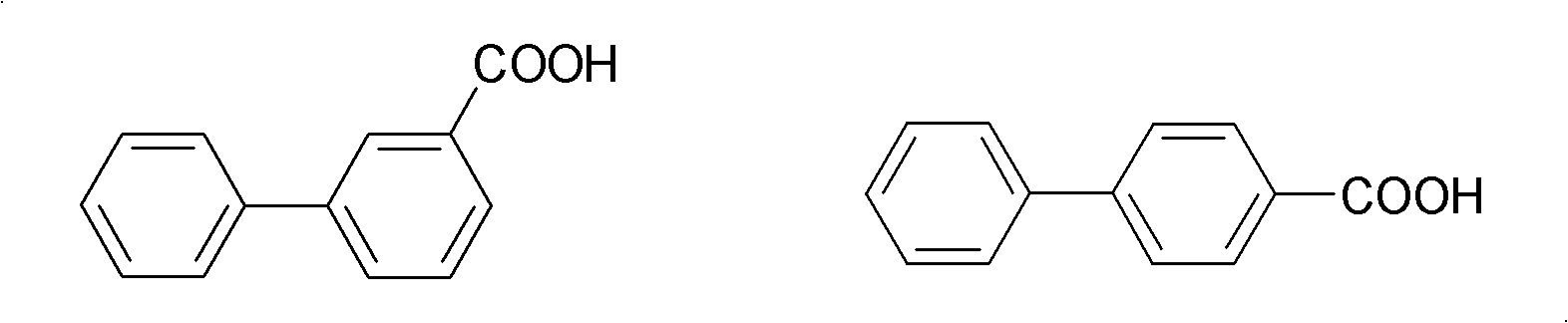

Inclusion separating method and application of isomerides of 3-diphenic acid and 4-diphenic acid

A technology of isomers and diphenylformic acid, which is applied in the field of separation and purification of diphenylformic acid isomers, can solve the problems of unsuitability for large-scale production, high energy consumption of separation methods, and small processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

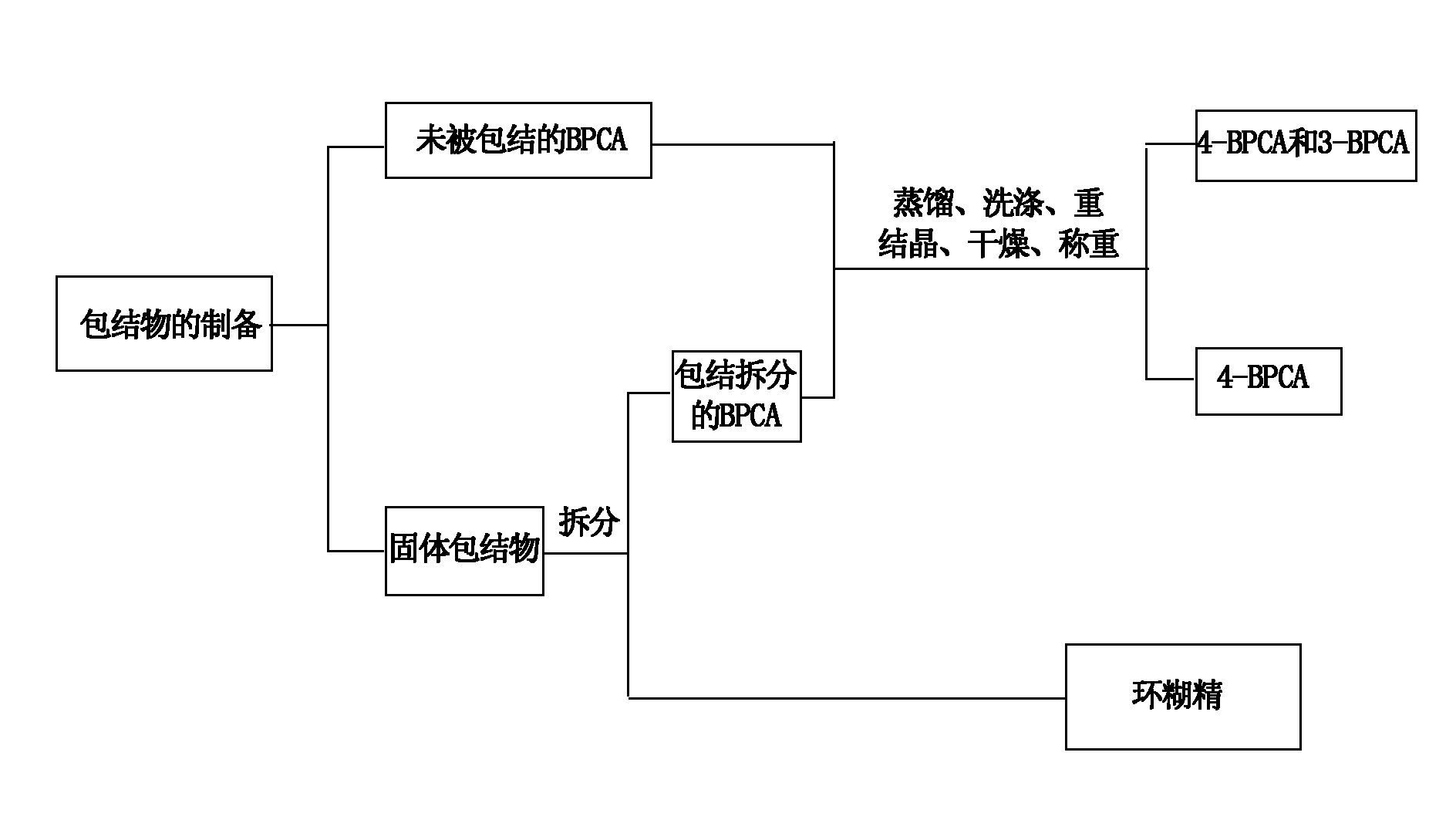

Method used

Image

Examples

Embodiment 1

[0030] Example 1: First prepare β-cyclodextrin into a saturated aqueous solution at 60°C, perform constant temperature magnetic stirring for 2 hours, then add the ethanol solution of diphenylcarboxylic acid dropwise to the above β-cyclodextrin with a molar material ratio of 1:1.5 In the saturated aqueous solution of dextrin, take out the Erlenmeyer flask from the water bath after reacting for 6 hours, let it stand at room temperature for 48 hours, and the inclusions are cooled and precipitated. Then the inclusions were washed three times with distilled water and absolute ethanol respectively, and the inclusions were collected. Dissolve the inclusions in ethanol solution, heat to reflux, adjust the constant temperature magnetic stirrer, control the temperature of the water bath to 88°C, adjust the speed to max, heat to reflux, and split for 2 hours; then filter twice, collect the filtrate, and use to be distilled. By distillation, the filtrate and the solvent in the mother liq...

Embodiment 2

[0031]Example 2: First make β-cyclodextrin into a saturated aqueous solution at 65°C, perform constant temperature magnetic stirring for 2.5 hours, and then add the ethanol solution of diphenylcarboxylic acid dropwise to the above β-cyclodextrin with a molar material ratio of 1:2 In the saturated aqueous solution of cyclodextrin, the conical flask was taken out from the water bath after reacting for 7 hours, and allowed to stand at room temperature for 54 hours, and the inclusion complexes were cooled and precipitated. Then the inclusions were washed three times with distilled water and absolute ethanol respectively, and the inclusions were collected. Dissolve the inclusion complex in ethanol solution, and heat to reflux, adjust the constant temperature magnetic stirrer, control the temperature of the water bath to 89°C, adjust the speed to max, heat to reflux, and split for 2.5h; then filter twice, collect the filtrate, to be distilled. By distillation, the filtrate and the ...

Embodiment 3

[0032] Example 3: First prepare the β-cyclodextrin into a saturated aqueous solution at 70°C, perform constant temperature magnetic stirring for 3 hours, and then add the ethanol solution of diphenylformic acid dropwise to the above β-cyclodextrin with a molar material ratio of 1:2.5. In the saturated aqueous solution of dextrin, take the conical flask out of the water bath after reacting for 8 hours, let it stand at room temperature for 60 hours, and the inclusion complexes are cooled and precipitated. Then the inclusions were washed three times with distilled water and absolute ethanol respectively, and the inclusions were collected. Dissolve the inclusions in ethanol solution, heat to reflux, adjust the constant temperature magnetic stirrer, control the temperature of the water bath to 90°C, adjust the speed to max, heat to reflux, and split for 3 hours; then filter twice, collect the filtrate, and use to be distilled. By distillation, the filtrate and the solvent in the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com