Preparation method of heat resistant acetal wire enamel

A technology of acetal varnish and wire-covered varnish, which is applied in the direction of coating, etc., can solve the problems that the solvent formula does not fully consider the workability, poor adhesion between the paint film and the conductor, and cannot meet the requirements of use, so as to achieve good process adaptability and product quality. The effect of good consistency and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

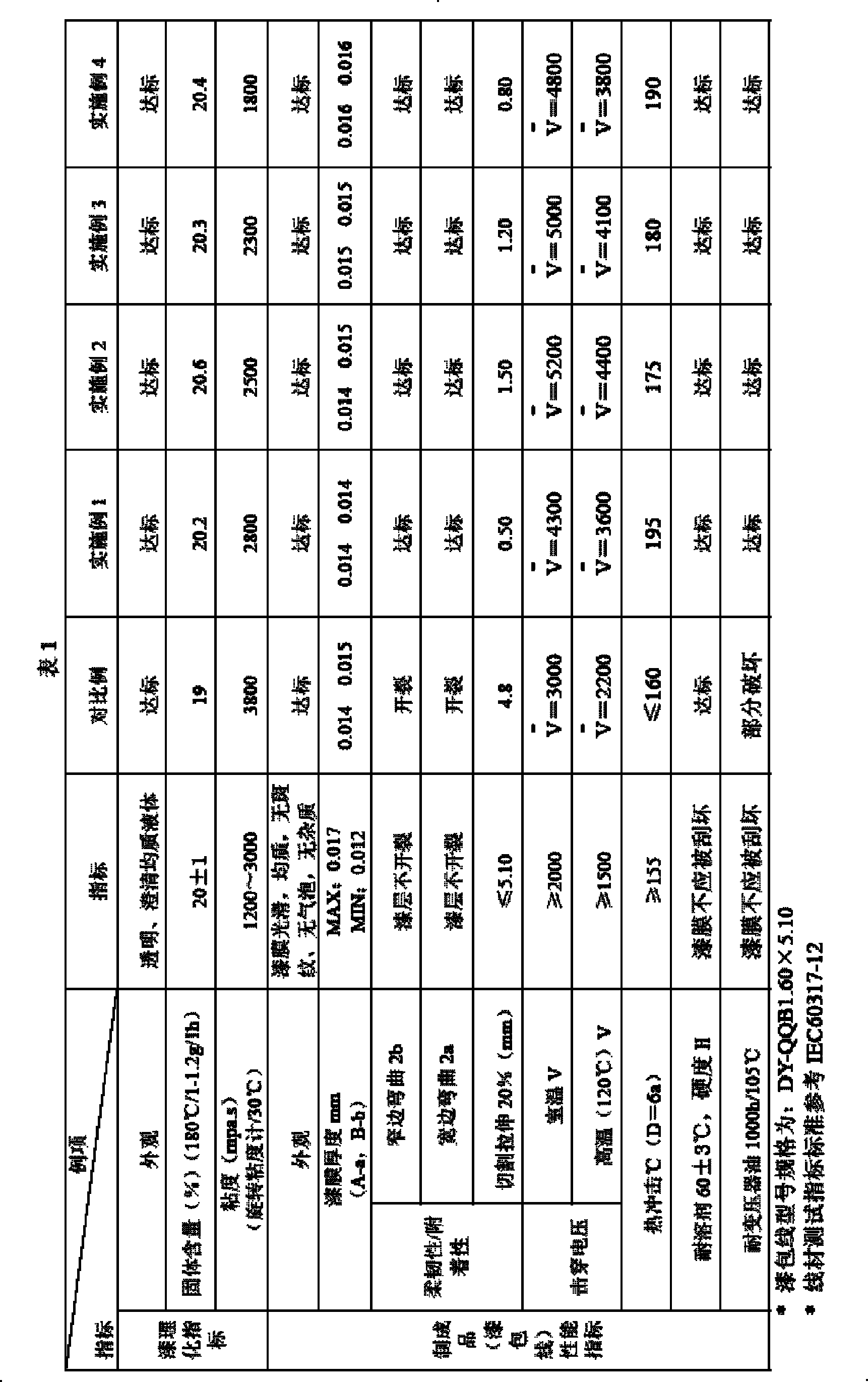

Embodiment 1

[0045] According to the molar ratio, add 240 parts of cresol, 360 parts of xylene and 100 parts of butanol into the reaction kettle with agitator and reflux pipe, turn on the agitator and heat it, when the temperature reaches 50±5℃, at 0.5 Within 1 hour, add 125 parts of polyvinyl acetal resin in batches by feeding gradually, keep stirring at 80±5°C for 3 hours, cool to 50±5°C, and make semi-finished product A; Add 40 parts of cresol and 86 parts of xylene into the reaction kettle with agitator and reflux tube, turn on the agitator and heat, put 62 parts of novolac epoxy resin, keep it at 60±5℃ for 2 hours, and cool to 50±5°C to prepare semi-finished product B; put semi-finished product B into semi-finished product A and stir evenly, then add 28 parts of silicone resin and 4 parts of melamine resin, keep warm at 50±5°C / 2h, until the liquid is clear and homogeneous, Cool down to less than 45°C, add 0.1 part of leveling agent, stir for 1 hour, and filter to obtain the finished p...

Embodiment 2

[0047] According to the molar ratio, add 260 parts of cresol, 330 parts of xylene and 120 parts of butanol into the reaction kettle with agitator and reflux tube, turn on the agitator and heat it, when the temperature reaches 50±5℃, at 0.5 Within 1 hour, add 100 parts of polyvinyl acetal resin in batches by feeding step by step, keep stirring at 80±5°C for 3 hours, cool to 50±5°C, and make semi-finished product A; Add 50 parts of cresol and 90 parts of xylene into a reaction kettle with a stirrer and a reflux pipe, turn on the stirrer and heat, put in 65 parts of novolac epoxy resin, keep it at 60±5°C for 2 hours, and cool to Prepare semi-finished product B at 50±5°C; put semi-finished product B into semi-finished product A and stir evenly, then add 34 parts of silicone resin and 7 parts of melamine resin, keep warm at 50±5°C / 2h, until the liquid is clear and homogeneous, Cool down to less than 45°C, add 0.15 parts of leveling agent, stir for 1 hour, and filter to obtain the f...

Embodiment 3

[0049]According to the molar ratio, add 250 parts of cresol, 320 parts of xylene and 140 parts of butanol into the reaction kettle with agitator and reflux pipe, turn on the agitator and heat it, when the temperature reaches 50±5℃, at 0.5 Within 1 hour, add 105 parts of polyvinyl acetal resin in batches by feeding step by step, keep stirring at 80±5°C for 3 hours, cool to 50±5°C, and make semi-finished product A; Add 45 parts of cresol and 85 parts of xylene into the reaction kettle with agitator and reflux pipe, turn on the agitator and heat it, add 60 parts of novolac epoxy resin, keep it at 60±5℃ for 2 hours, and cool to 50±5°C to prepare semi-finished product B; put semi-finished product B into semi-finished product A and stir evenly, then add 32 parts of silicone resin and 6 parts of melamine resin, keep warm at 50±5°C / 2h, until the liquid is clear and homogeneous, Cool down to less than 45°C, add 0.12 parts of leveling agent, stir for 1 hour, and filter to obtain the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com