Full combustion smoke gas excess heat reclaiming system of argon oxygen decarburization converter

A technology of argon-oxygen decarburization and flue gas waste heat, which is applied in the direction of furnaces, waste heat treatment, furnace components, etc., can solve problems such as unfavorable flue gas waste heat recovery, increased investment and operation costs, and difficult operation and maintenance, so as to solve flue gas temperature fluctuations Large size, convenient operation and maintenance, and the effect of ensuring the life of the flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

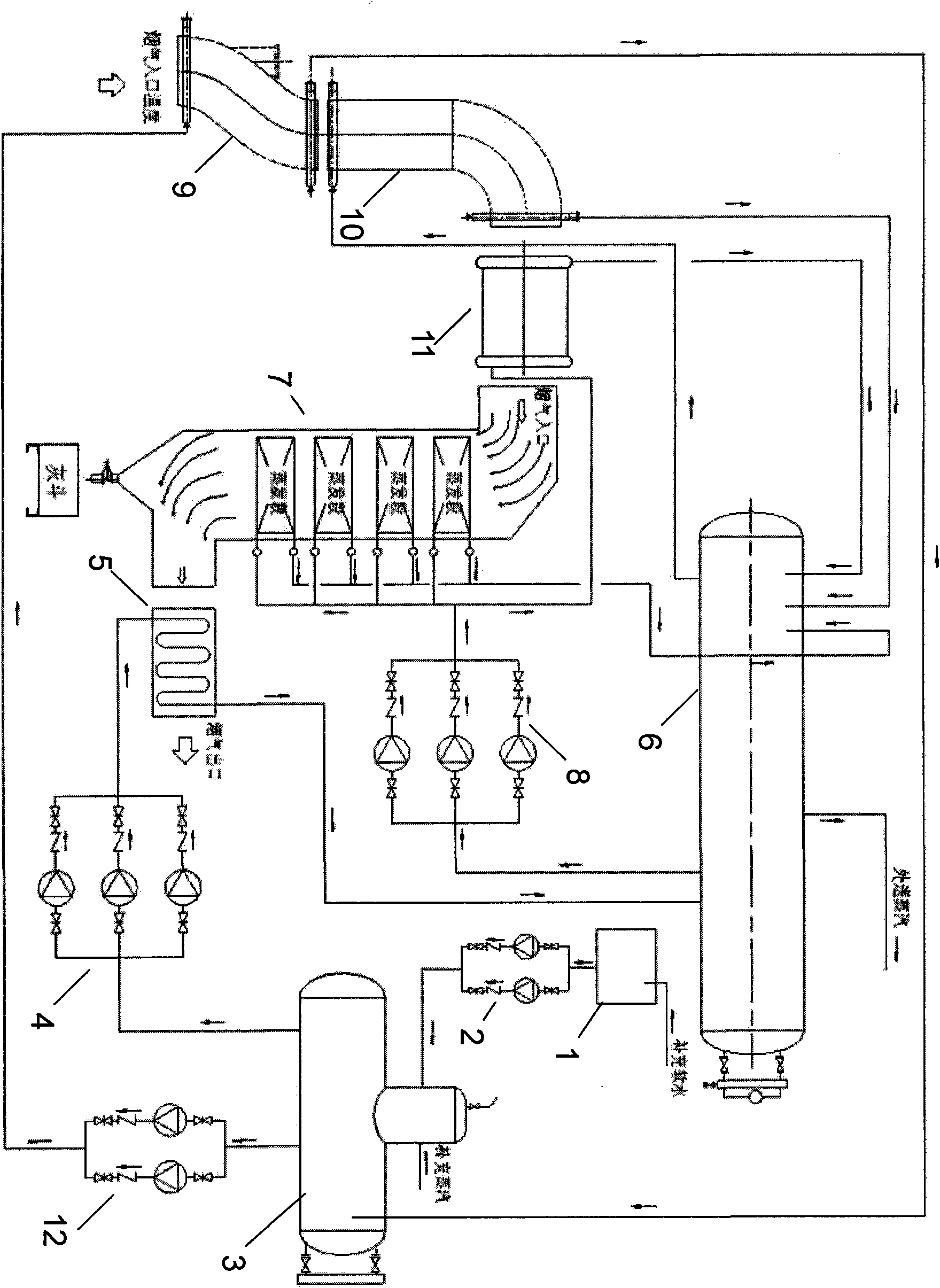

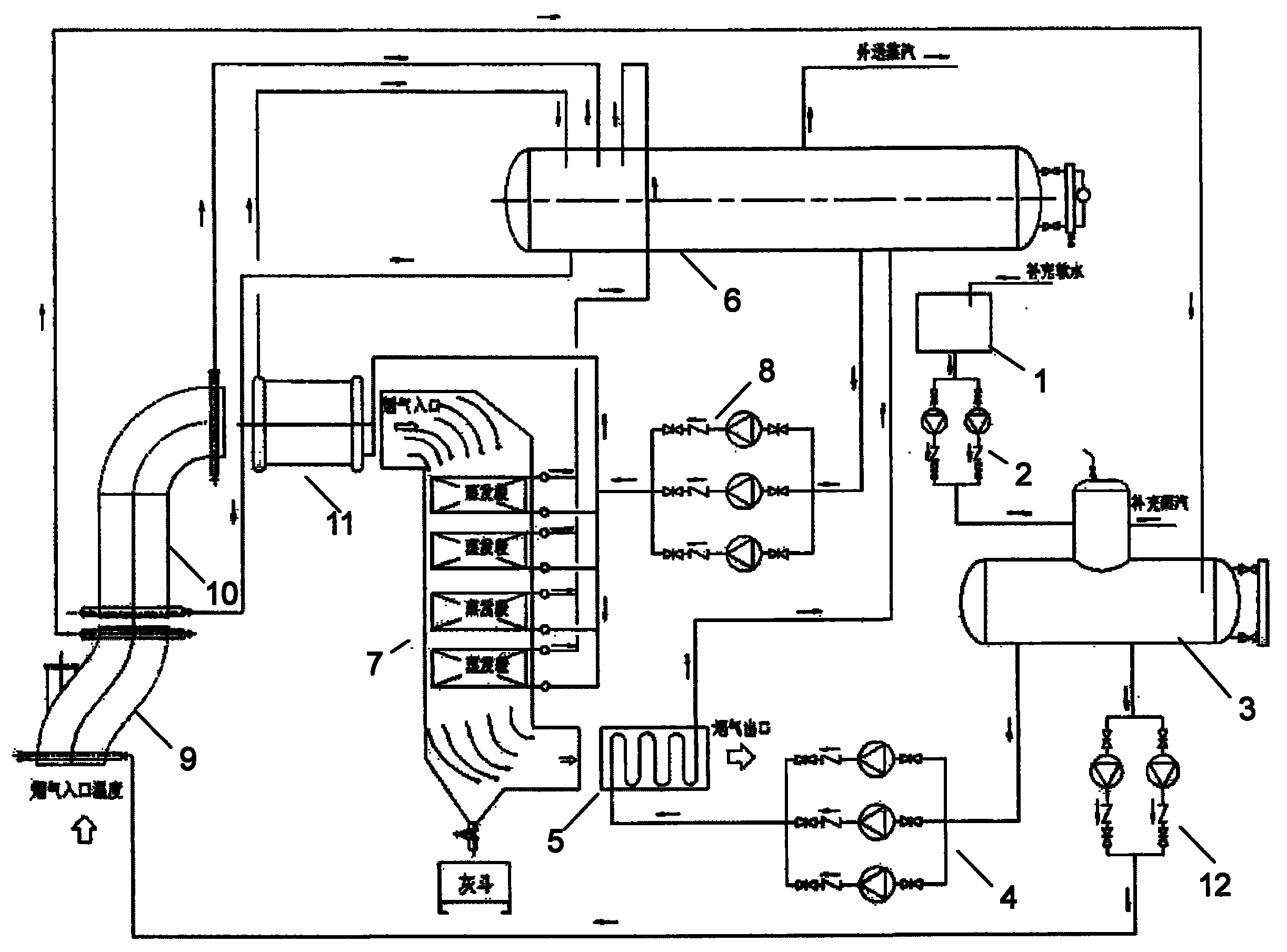

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] Referring to the accompanying drawings, the present invention provides a waste heat recovery system for argon-oxygen decarburization converter full combustion flue gas, which adopts the waste heat recovery mode of vaporization flue, convection heat exchange device and economizer. The whole device is mainly composed of vaporization flue 9 at the furnace mouth section, vaporization inclined flue 10, horizontal turning flue 11, convective heat exchange device 7, economizer 5, steam drum 6, deaerator 3, soft water tank 1, oxygen removal It is composed of feed water pump 2, boiler feed water pump 4, low pressure forced circulation pump 12, medium pressure forced circulation pump 8, etc.

[0035] The convective heat exchange device 7 is arranged vertically, its inlet is connected to the vaporization flue, and an economizer 5 is installed on its outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com