Sulfuric acid dew point corrosion resistant steel

A dew point corrosion and sulfuric acid resistance technology, applied in the field of acid corrosion resistant steel and sulfuric acid dew point corrosion resistant steel, can solve the problems of affecting heat exchange efficiency, difficult construction, difficult implementation, etc., to achieve outstanding progress, improve acid corrosion resistance, and significantly effect of substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

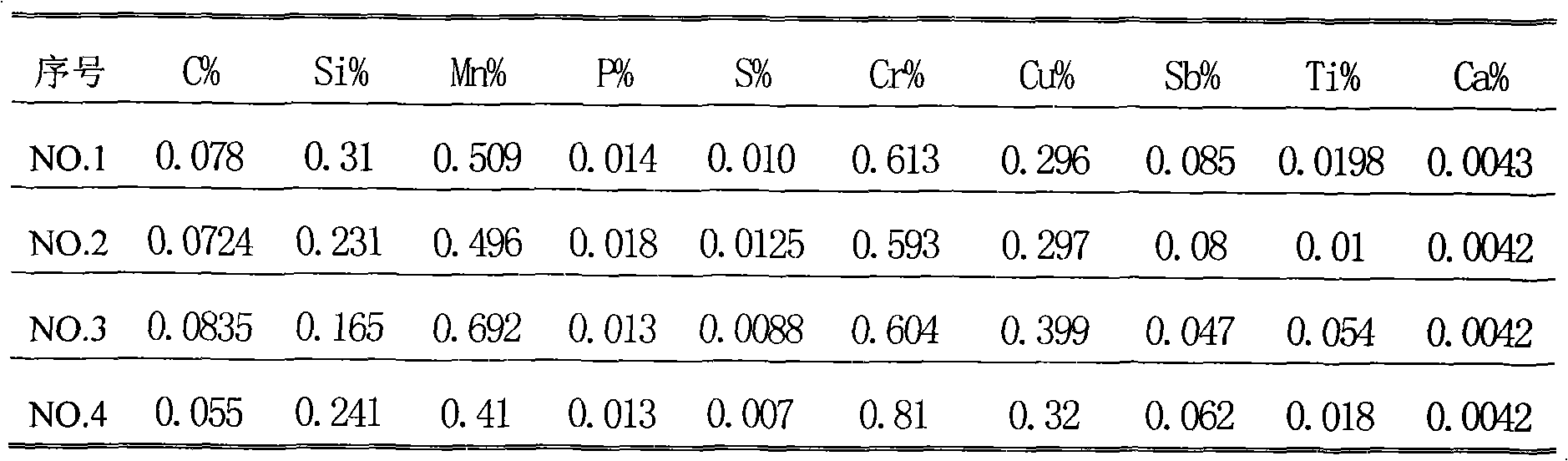

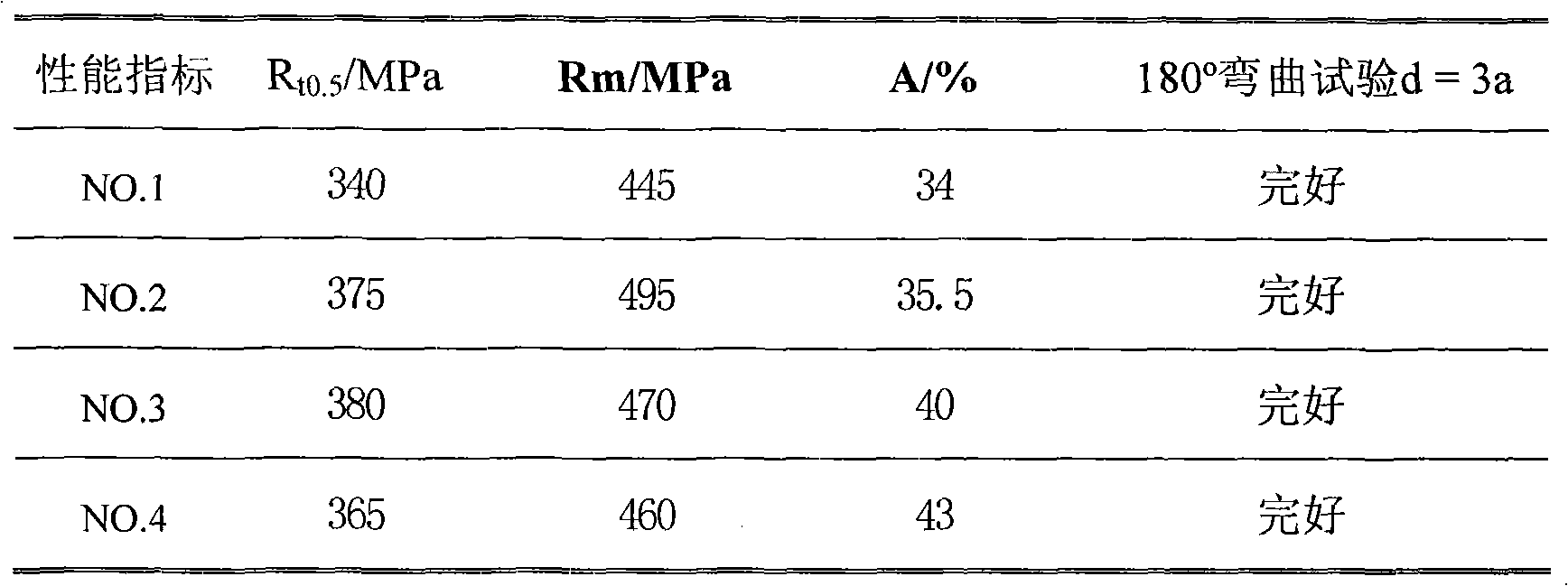

Embodiment 1

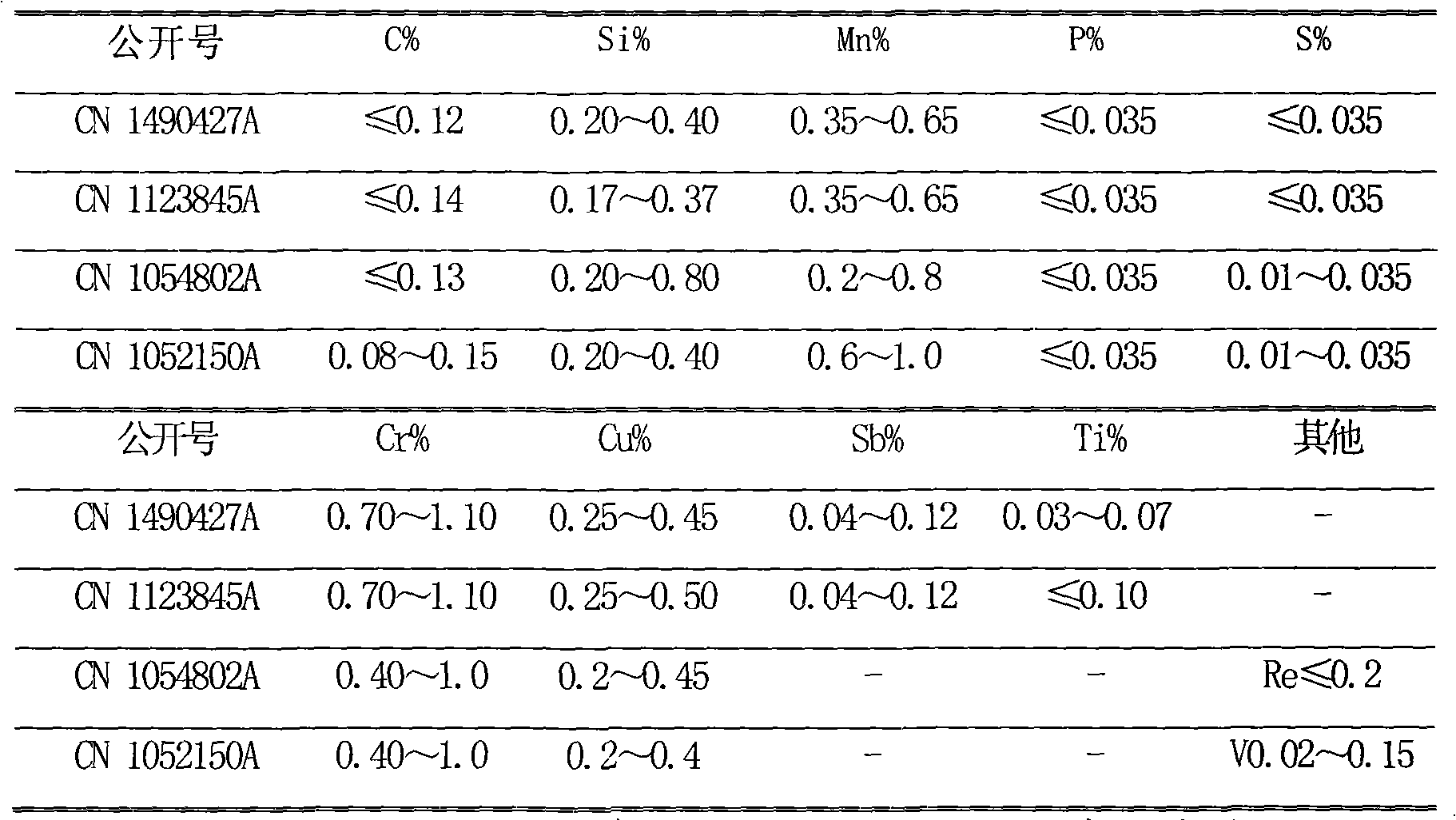

[0020] The mass percentages of the various components of the sulfuric acid dew point corrosion-resistant steel (code name BNS440) in this example are shown in No. 1 of Table 2, and the traditional long process of manufacturing steel products is adopted: blast furnace ironmaking → molten iron pre-desulfurization → converter top-bottom compounding Converting→Ar station / or LF furnace refining→continuous casting→continuous casting slab without defect→inspection→heating→brushing→finish rolling→cooling→coiling→finished hot rolled coil. Production control requirements: Pre-desulfurization of molten iron to control S element below 0.010%; composition adjustment of C, Si, Mn, S, and P in converter top-bottom compound blowing, desulphurization and fine-tuning of composition through Ar station / or LF furnace refining To meet the control requirements, at the same time feed an appropriate amount of iron-calcium wire for secondary refining to ensure the purity of molten steel; continuous cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com