Copper powder for electrically conductive paste, and electrically conductive paste

A conductive paste technology, applied in the field of conductive paste, can solve the problem of poor oxidation resistance, and achieve the effect of excellent oxidation resistance and fine copper powder particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

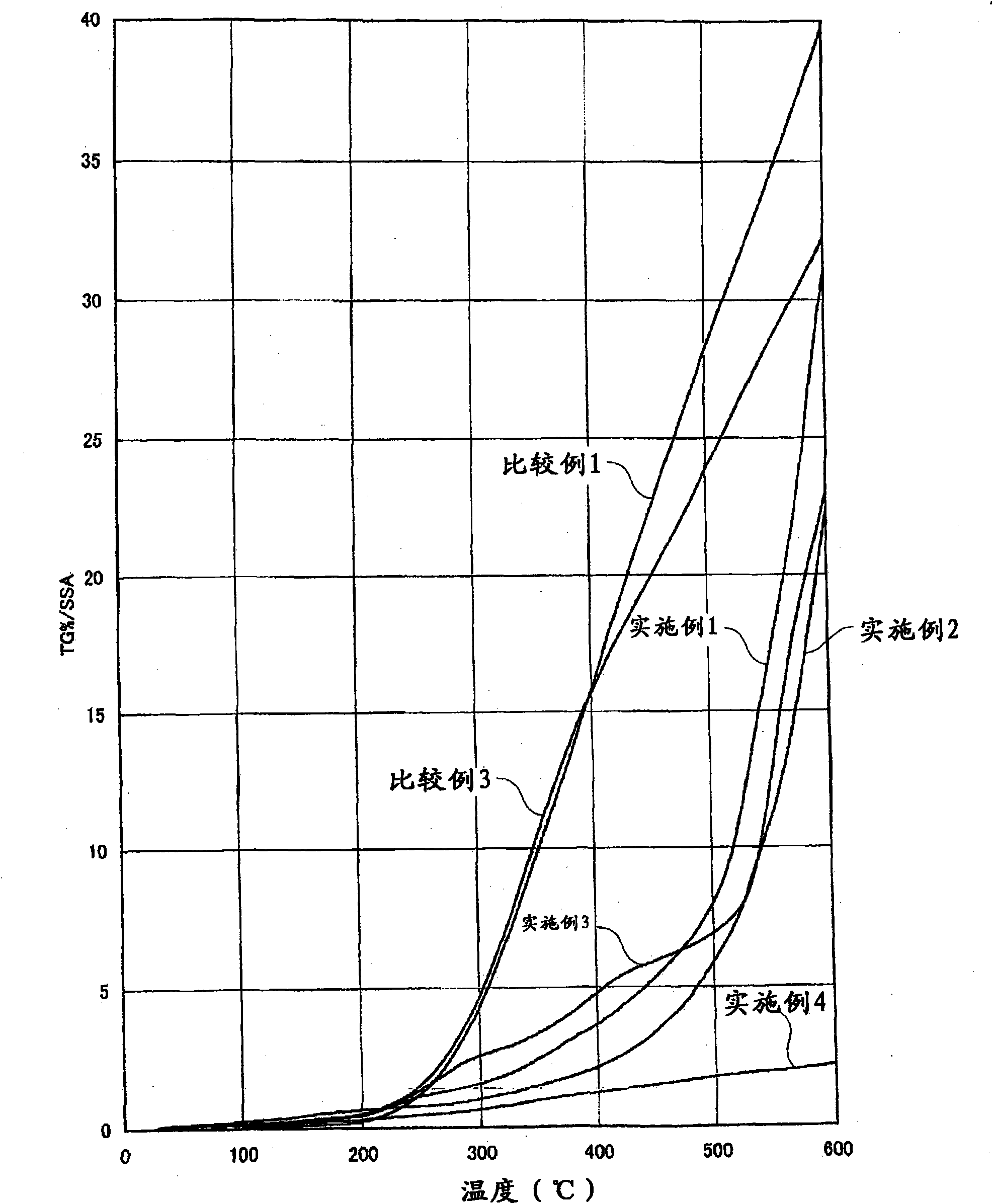

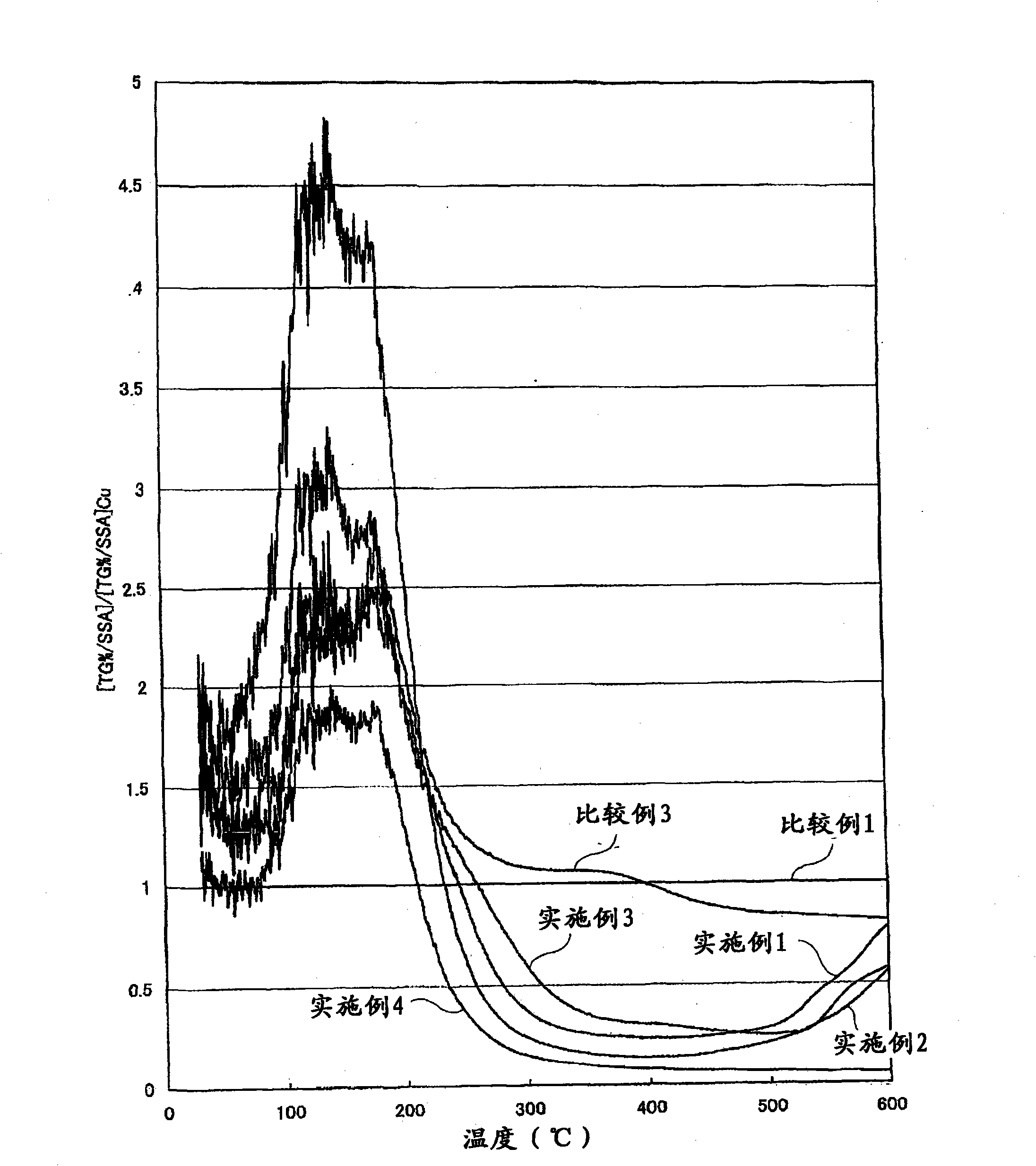

Embodiment 1

[0058] After filling the chamber and raw material melting chamber of the gas atomization device (manufactured by Nisshin Giken Co., Ltd., NEVA-GP2 type) with nitrogen, the raw material is heated and melted in the carbon crucible in the melting chamber to form a melt (after melting 1.77 g of metal silicon (NIKSIL manufactured by Nippon Metal Chemical Industry Co., Ltd.) was added to the metal solution of electrolytic copper to prepare 800 g of the metal solution, which was fully stirred and mixed). Thereafter, the metal solution was sprayed at 1250° C. and 3.0 MPa from a nozzle with a diameter of φ1.5 mm to obtain a copper powder containing silicon in the particle. Then, sieve was performed with a 53 μm test sieve, and the copper powder that passed through the sieve holes was used as the final copper powder. Table 2 shows the characteristics of the obtained copper powder.

Embodiment 2~4

[0060] Except having changed the metal silicon addition amount as shown in Table 1, it carried out similarly to Example 1, and obtained copper powder.

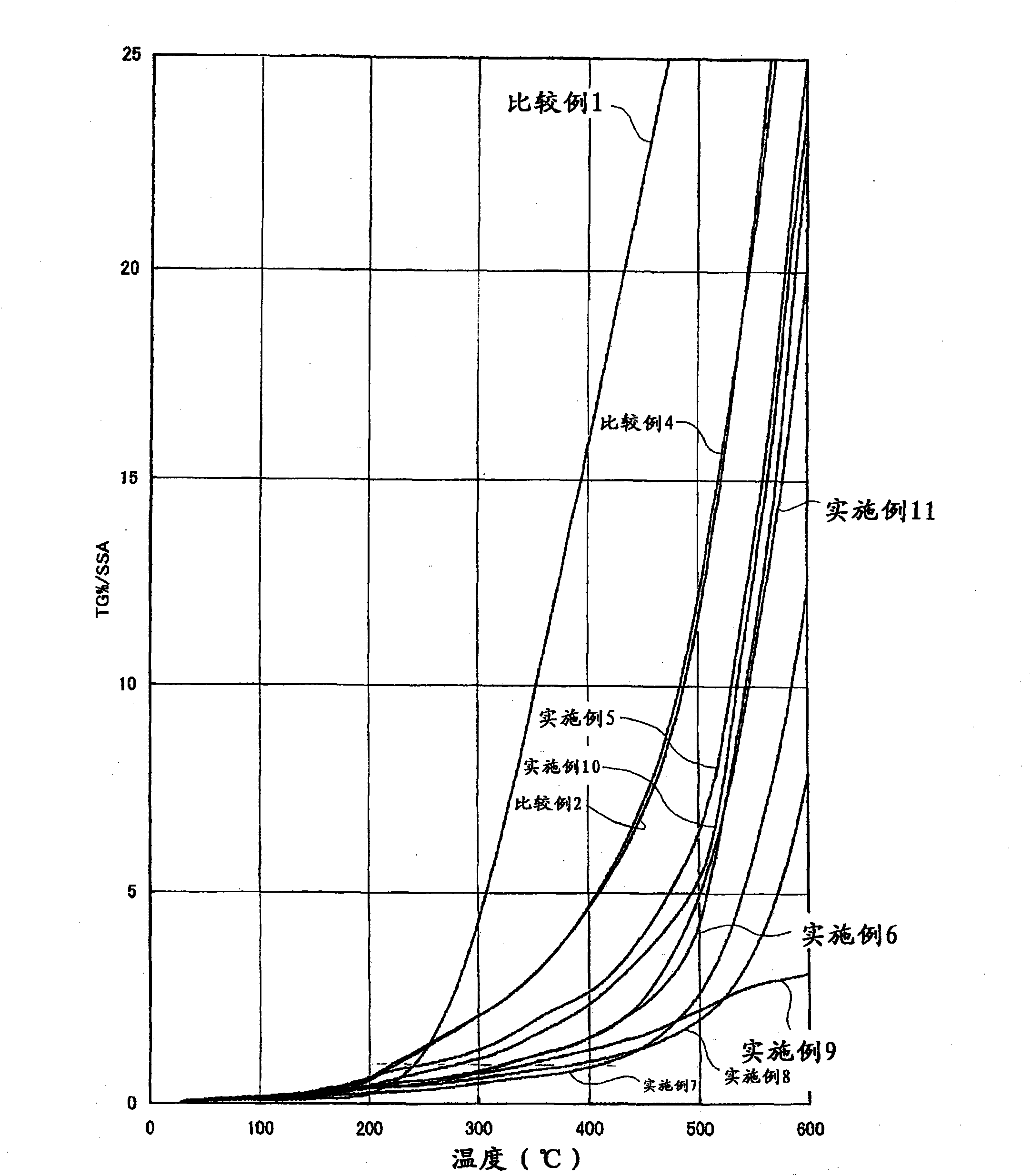

Embodiment 5~11

[0062] Copper powder was obtained in the same manner as in Example 1, except that a copper-phosphorus master alloy (phosphorus grade: 15% by mass) was added as shown in Table 1 in addition to metal silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com