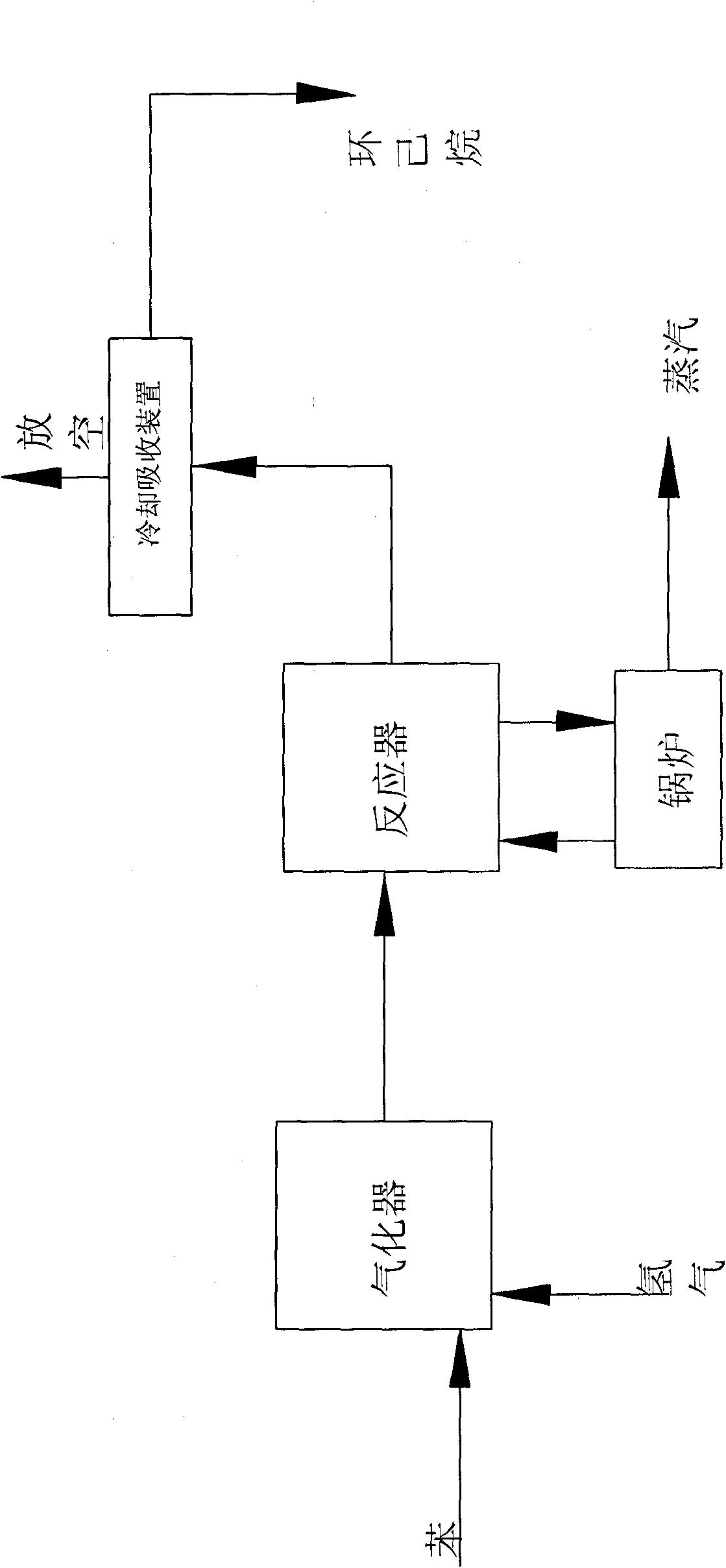

Device for producing cyclohexane by adding hydrogen in benzene and synthesis process

A synthesis process and cyclohexane technology, applied in the directions of hydrogenation to hydrocarbon production, organic chemistry, etc., can solve the problems of poor operation stability of the reactive distillation column, large degree of back-mixing in the reactor, and restriction of large-scale production, etc., and it is easy to reach the reaction temperature. Control, reduce equipment investment, and improve the effect of control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

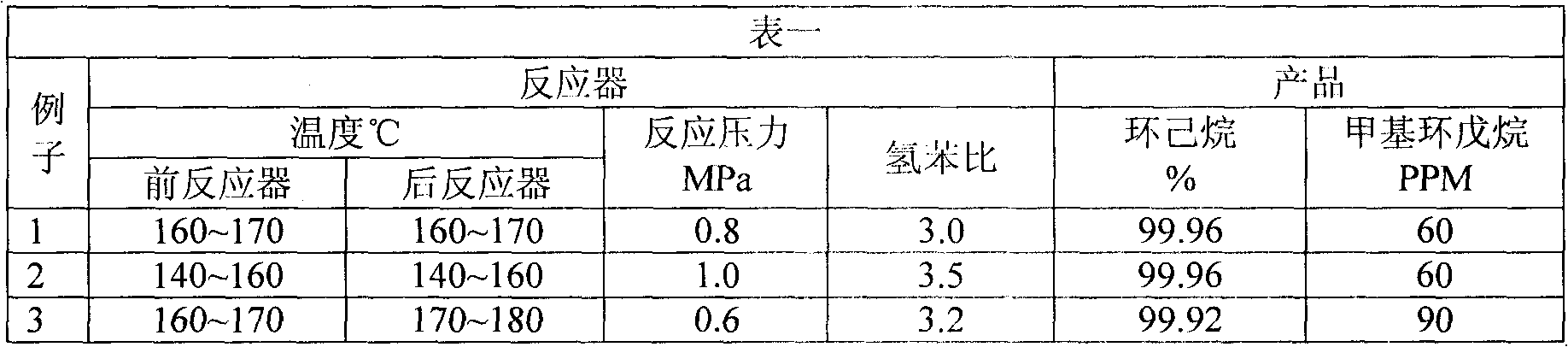

Examples

Embodiment Construction

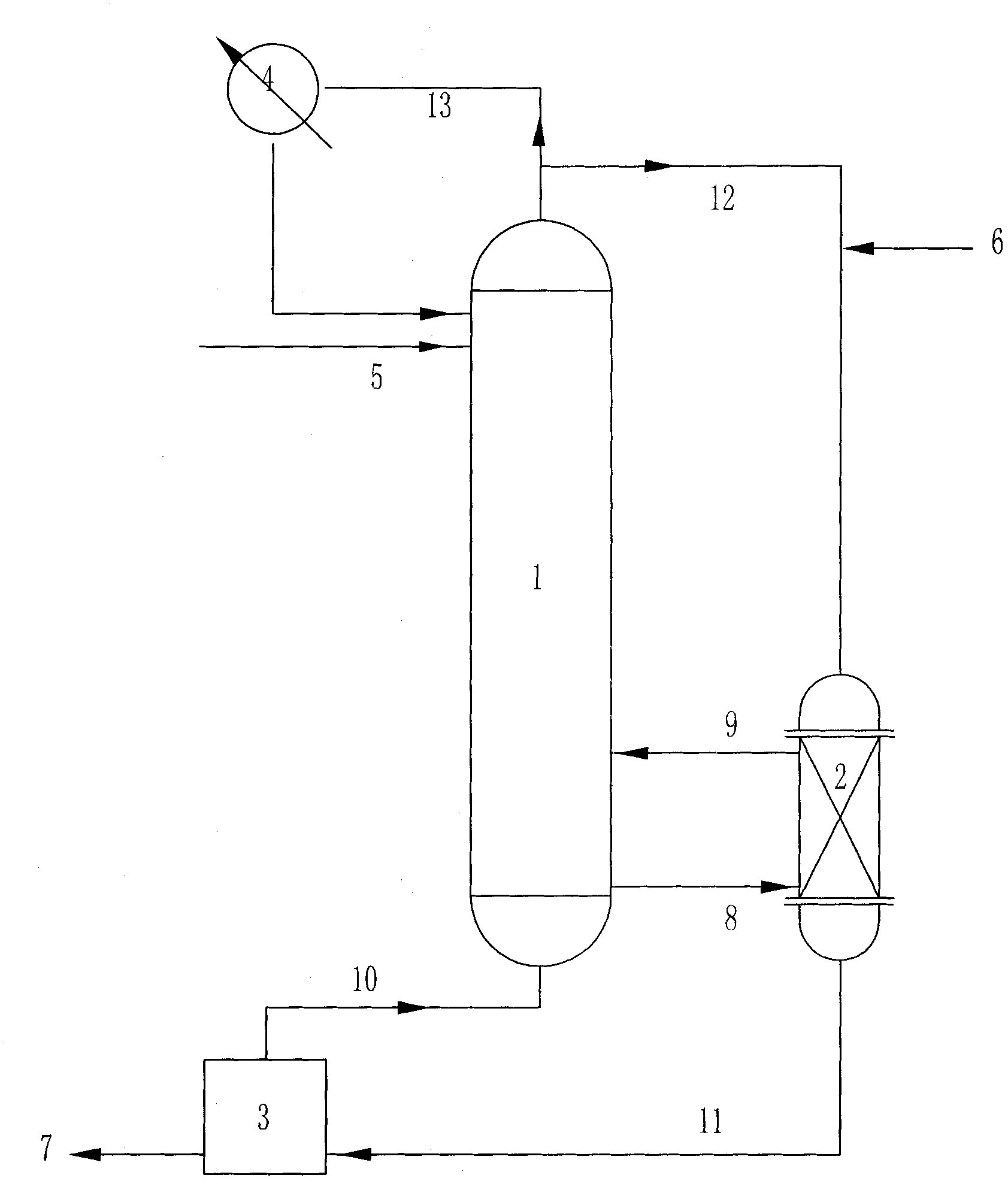

[0020] figure 2 Schematic diagram of the device for producing cyclohexane by hydrogenation of benzene in the present invention. The device mainly includes a gasification tower 1 and a reactor 2 . Gasification tower 1 is equipped with fillers to facilitate gas-liquid contact; reactor 2 is composed of two series-connected 304 stainless steel fixed-bed catalytic reactors. The upper part of the gasification tower 1 has a liquid-phase benzene inlet 5, and the lower part of the gasification tower 1 has a liquid-phase benzene outlet. The liquid-phase benzene outlet is connected to the shell-side inlet of the reactor 2 through the pipeline 8, so that the liquid benzene in the gasification tower 1 can enter the shell-side of the reactor, and the reaction heat in the tube-side of the reactor is removed by gasification. The outlet of the shell side of the reactor 2 is connected to the gasification tower 1 through the pipeline 9, and the top of the gasification tower 1 has a gas phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com