Functional hyperbranched polymer supported platinum catalyst, preparation method and application thereof

A hyperbranched polymer, platinum catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problem of low catalytic activity of platinum catalyst, etc. Excellent rheological properties, saving production costs and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

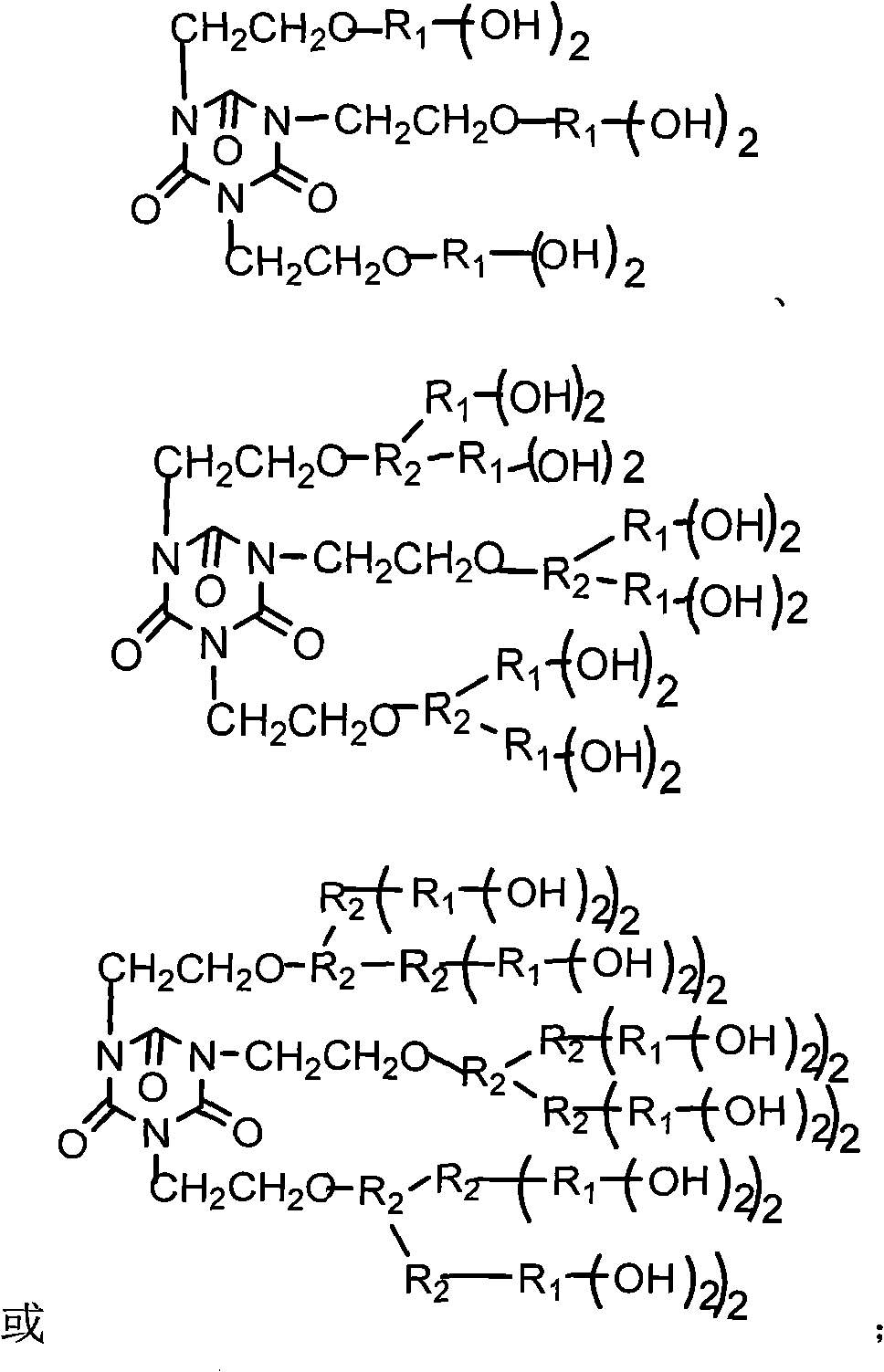

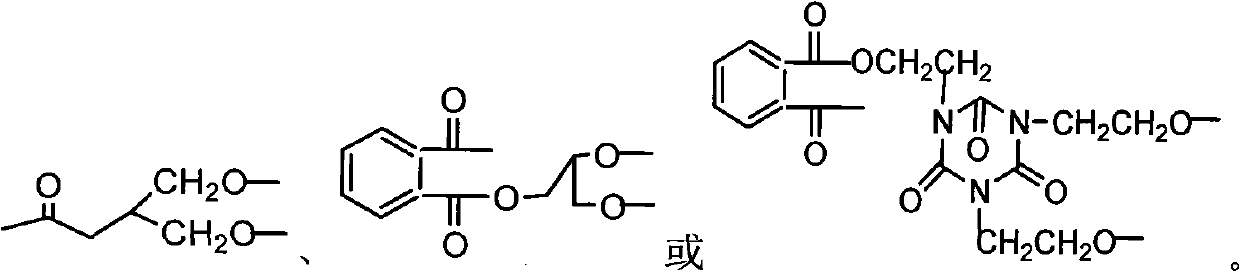

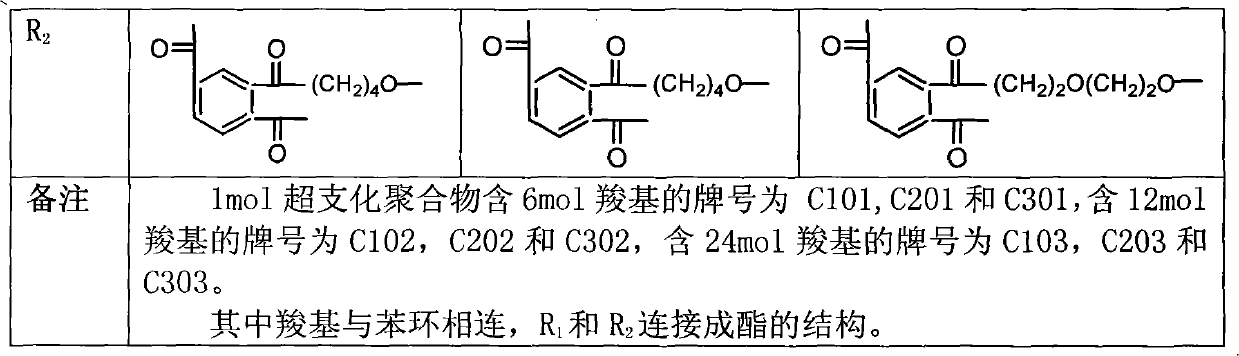

Method used

Image

Examples

Embodiment 1

[0026] A kind of terminal hydroxyl hyperbranched polymer immobilized platinum catalyst, its preparation method is as follows:

[0027] 0.2g analytical pure chloroplatinic acid is dissolved in the mixed solvent of 20g analytical pure isopropanol and 10g analytical pure tetrahydrofuran, add 10.0g terminal hydroxyl hyperbranched polymer H101 (purity is greater than 95wt%) and 0.3g analytical pure sodium bicarbonate mixes Evenly, after ultrasonication at 700W power for 20min, under normal pressure nitrogen condition, 30°C stirring reaction for 6h, and then stand at room temperature for 6h, evaporate the solvent under vacuum condition at 60°C to obtain loose powder, and then Put the powder into a Buchner funnel lined with filter paper, wash 3 times with 20ml of distilled water each time, wash out the sodium chloride, and then dry it in vacuum at 60°C to obtain a platinum-immobilized catalyst for a hydroxyl-terminated hyperbranched polymer. The platinum content is 0.75wt% (denoted a...

Embodiment 2

[0029] A kind of terminal hydroxyl hyperbranched polymer immobilized platinum catalyst, its preparation method is as follows:

[0030] Dissolve 0.4g of analytically pure sodium chloroplatinate in 40g of analytically pure n-propanol, add 10.0g of hydroxyl-terminated hyperbranched polymer H102 (purity greater than 95wt%) and 0.35g of analytically pure sodium bicarbonate and mix homogeneously, under 800W power After ultrasonication for 18 minutes, stir and react at 40°C for 5h under normal pressure nitrogen, then let stand at room temperature for 6h, evaporate the solvent under vacuum at 60°C to obtain a loose powder, and then put the powder into a filter paper pad In the Buchner funnel, wash 3 times with 20ml of distilled water each time, wash out the sodium chloride, and then dry in vacuum at 60°C to obtain the immobilized platinum catalyst of the hydroxyl-terminated hyperbranched polymer, and the platinum content is calculated to be 1.39wt%. (Denoted as Pt / H102-139).

Embodiment 3

[0032] A kind of terminal hydroxyl hyperbranched polymer immobilized platinum catalyst, its preparation method is as follows:

[0033] Dissolve 0.8g of analytically pure chloroplatinic acid in 60g of analytically pure isopropanol, add 10.0g of hydroxyl-terminated hyperbranched polymer H103 (purity greater than 95wt%) and 1.0g of analytically pure sodium bicarbonate and mix homogeneously, under a power of 900W After ultrasonication for 16 minutes, stir and react at 50°C for 4h under normal pressure nitrogen, then let stand at room temperature for 6h, evaporate the solvent under vacuum at 60°C to obtain a loose powder, and then put the powder into a filter paper pad In the Buchner funnel, wash 3 times with distilled water 20ml each time, wash out sodium chloride, then obtain the terminal hydroxyl hyperbranched polymer immobilized platinum catalyst at 60 ℃ of vacuum drying, after calculating its platinum content is 3.00wt% ( Recorded as Pt / H103-300).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com