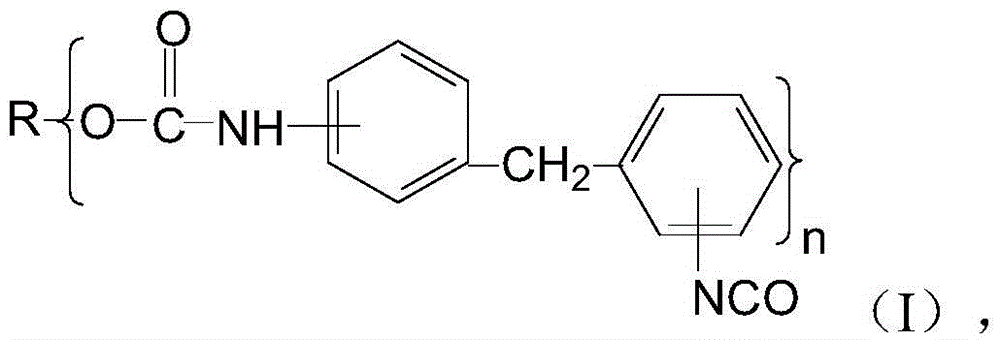

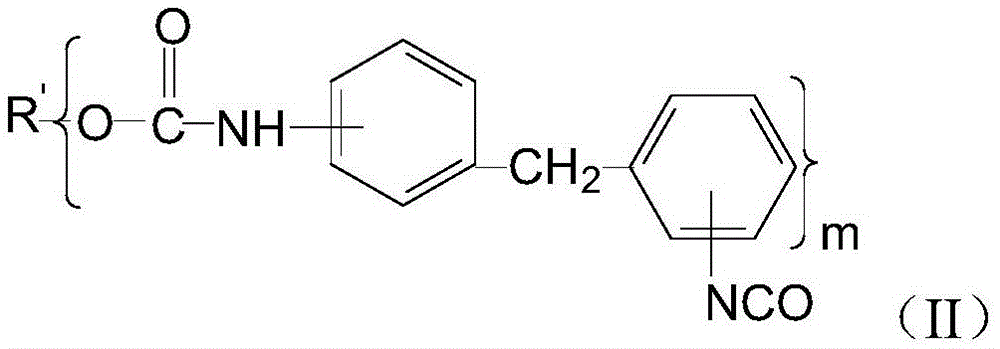

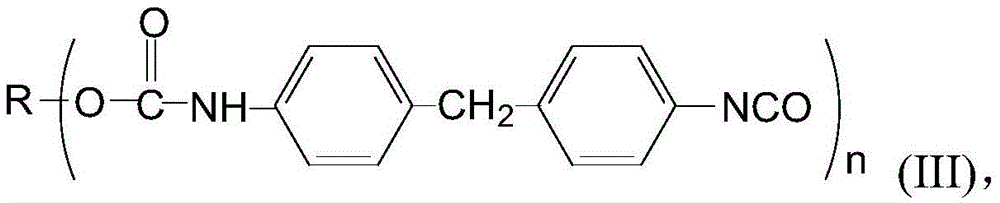

Prepolymer based on diphenylmethane diisocyanate as polyurethane coating curing agent and preparation method thereof

A technology of diisocyanate and diphenylmethane, applied in the field of prepolymer based on diphenylmethane diisocyanate as polyurethane coating curing agent and its preparation, can solve the poor compatibility of hydroxyl acrylic resin and alkyd resin , Acetate solution has poor storage stability and low functionality, and achieves the effect of clear and transparent appearance, low color and low toxicity of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0038] 26.8kg of 1,1,1-trimethylolpropane and 26.8kg of dipropylene glycol were vacuum dehydrated at 105°C to 115°C for 2 to 4 hours before use.

[0039] At this moment, the equivalent ratio of 1,1,1-trimethylolpropane and dipropylene glycol is 6:4,

[0040] Keep its moisture content below 0.04%. Under nitrogen protection, put 262.5kg of diphenylmethane diisocyanate and 316.1kg of butyl acetate into the reaction vessel and stir evenly, maintaining the temperature at 60°C.

[0041] Then slowly add 1,1,1-trimethylolpropane dropwise into the reactor, and keep stirring in the reactor during the dropwise addition to make the materials mix and react evenly, and the dropping time is 90 minutes. Continue to react at 60°C under stirring for 4 hours; then slowly add dipropylene glycol dropwise into the reactor, and keep stirring in the reactor during the dropwise addition to make the materials mix and react evenly, and the dropping time is 2 hours. After the dropwise addition, the rea...

no. 2 example

[0051] 24kg of 1,1,1-trimethylolethane and 38.4kg of tripropylene glycol were vacuum dehydrated at 105°C to 115°C for 2 to 4 hours before use.

[0052] At this moment, the equivalent ratio of 1,1,1-trimethylolethane and tripropylene glycol is 6:4,

[0053] Keep its moisture content below 0.04%. Under nitrogen protection, put 262.5kg of diphenylmethane diisocyanate and 216.6kg of butyl acetate into the reaction vessel and stir evenly, maintaining the temperature at 60°C.

[0054] Then slowly add 1,1,1-trimethylolethane dropwise into the reactor, and keep stirring in the reactor during the dropwise addition to make the materials mix and react evenly, the dropwise time is 90 minutes, and the dropwise addition is completed Then continue to react at 60°C under stirring for 4 hours, then slowly add tripropylene glycol dropwise into the reactor, keep stirring in the reactor during the dropping process to make the materials mix and react evenly, and the dropping time is 2 hours Afte...

no. 3 example

[0064] 26.8kg of 1,1,1-trimethylolpropane and 26.8kg of dipropylene glycol were vacuum dehydrated at 105°C to 115°C for 2 to 4 hours respectively to ensure that the water content was lower than 0.04%. Under the protection of nitrogen, put 262.5kg of diphenylmethane diisocyanate and 316.1kg of butyl acetate into the reaction vessel, mix and stir evenly, and keep the temperature at 60°C, then add 1,1,1-trimethylol After the propane and dipropylene glycol are fully mixed, slowly drop them into the reactor. During the dropping process, the reactor is kept stirring to make the material uniform. The dropping time is 90 minutes. After the dropping, continue to stir at 60°C React for 4 hours, cool down to below 40°C and discharge.

[0065] The curing agent prepared in the third example becomes turbid after being stored at 25° C. for 5 days, and separates after 10 days.

[0066] In this embodiment, in the preparation of the curing agent for polyurethane coatings, the dripping method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com