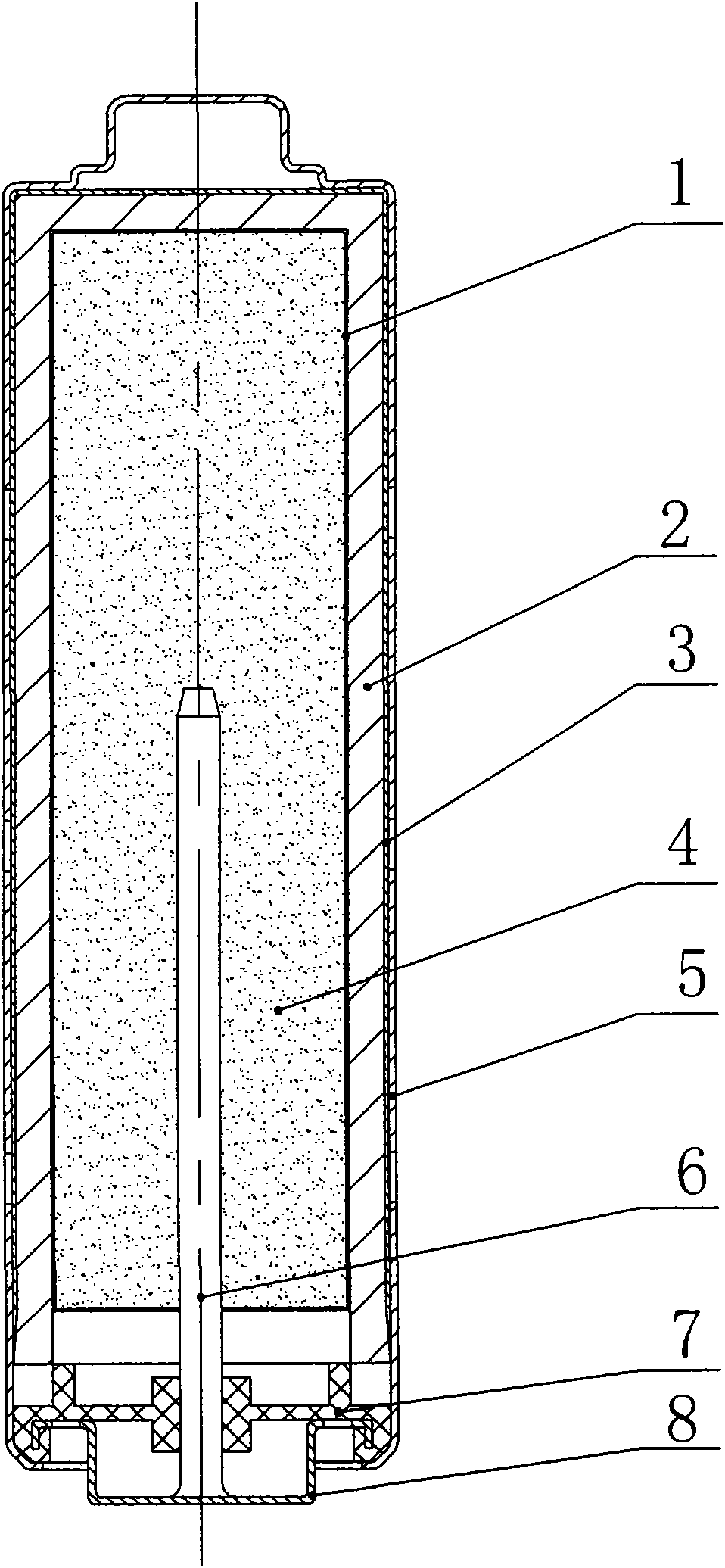

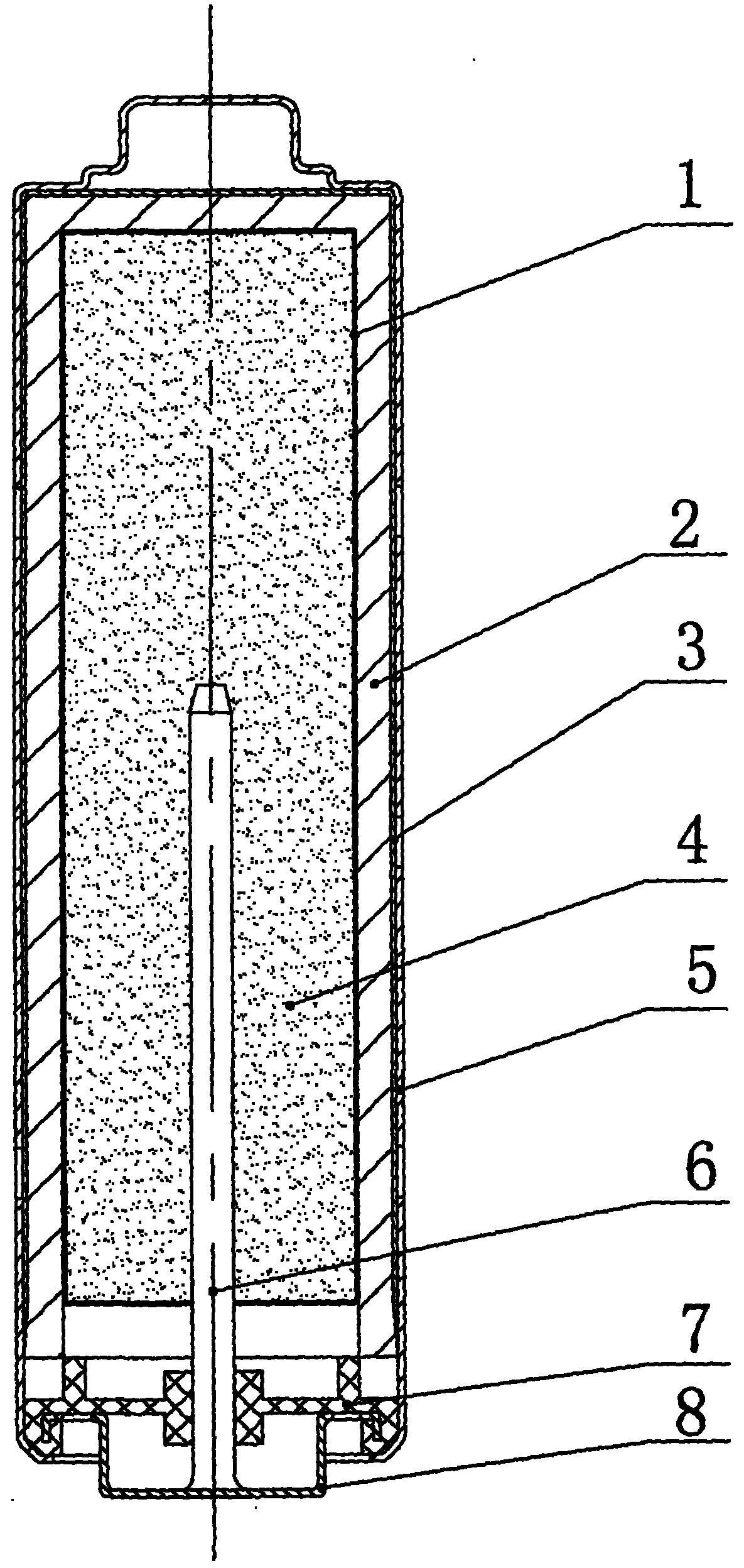

Novel method for sealing cylindrical zinc-air battery

A zinc-air battery and air electrode technology, which is applied to fuel cell half-cells and primary battery half-cells, battery electrodes, circuits, etc., to achieve stable working voltage, excellent strength, and excellent sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] 3. Preparation of the inner catalytic membrane of the air electrode

[0033] The catalytic layer is prepared according to the following ratio: the mixed material of the catalyst is configured by weight: polytetrafluoroethylene: 10-25%, acetylene black or carbon black: 45-75%, catalyst: 10-35%.

[0034] Described catalyst can be: MnO 2 , KMnO 4 , MnSO 4 , SnO 2 , Fe 2 o 3 ,Co 3 o 4 , Co, CoO, Fe, Pt and Pd, etc.

[0035] Add 2 times the weight of the aqueous solution to the above mixed material, fully mix and stir to agglomerate into a slurry, and then dry out the water in it, so that the soluble catalyst is dispersed and precipitated on the surface of the carbon black; add 3 times the organic Solvent (such as alcohol), after repeated rolling and fibrosis, is finally pressed to a specified thickness (0.05-0.2mm), which is used as a pre-embedded catalytic membrane.

[0036] 4. Molding and preparation of air electrode

[0037] ① Bond the catalytic membrane into a...

Embodiment 1

[0047] 1. First, prefabricate a stainless steel battery case with air holes.

[0048] 2. Add adhesive, conductive agent and remodeling material according to the weight ratio of 10%: 60%: 30%, and prepare waterproof powder for use after heat sealing and crushing; the adhesive is low-pressure polyethylene; The modified material is OP-10; the conductive agent is acetylene black.

[0049] 3. According to PTFE 10%; acetylene black 75%, MnO 2 A mixture of 15% by weight of the catalyst; add 2 times the weight of the aqueous solution to the above mixture, fully mix and stir to form a slurry, and then dry out the water in it, so that the soluble catalyst is dispersed and precipitated on the surface of the carbon black; Add 3 times alcohol to the final mixture, after repeated rolling and fibrosis, it is pressed to a thickness of 0.05mm, and it is used as a pre-embedded catalytic membrane.

[0050] 4. Bond the catalytic membrane into a cylindrical shape, pre-embed it in the hot-pressin...

Embodiment 2

[0056] Concrete method is the same as embodiment 1, and difference is:

[0057] In step 2, according to the weight ratio of 35:40:25, adhesive, conductive agent and remodeling material are added, and after heat sealing and crushing, waterproof powder is prepared for use; the adhesive is polytetrafluoroethylene; the The modified material described above is OP-10; the conductive agent described is acetylene black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com