Method for preparing non-toxic environmental-friendly epoxy plasticizer

An epoxy plasticizer, non-toxic and environmentally friendly technology, used in organic chemistry and other directions, can solve the problems of long production cycle, easy to cause explosion, increase in sewage volume, etc., to reduce production costs, reduce sewage treatment burden, and eliminate chemical factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

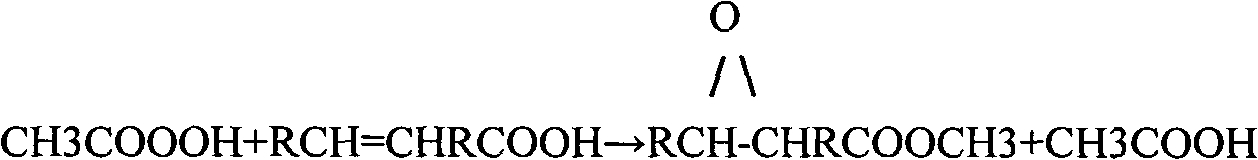

Method used

Image

Examples

Embodiment 1

[0028] In a 3000L reactor, put fatty acid methyl ester and glacial acetic acid (accounting for 15% by weight of fatty acid methyl ester) into the reactor in a corresponding proportion, heat up, start stirring and operate a closed cooling cycle device, heat up to 45°C and stop heating, Open the cooling water valve of the reaction kettle, add hydrogen peroxide (accounting for 35% of the mass proportion of fatty acid methyl ester) dropwise at a speed of 65g / s, the temperature of the reaction solution is controlled at 40-60°C, and the dropping time is 2 hours. Insulate and reflux for 2 hours to ensure that the epoxidation reaction is sufficient. Wash, neutralize, and distill under reduced pressure for 1.5 hours the crude epoxy plasticizer product, stop stirring and close the closed cooling cycle device, and dehydrate under reduced pressure to obtain non-toxic and environmentally friendly type epoxy plasticizer.

[0029] The closed cooling cycle device means that the reactor needs ...

Embodiment 2

[0033] In a 3000L reactor, put fatty acid methyl ester and glacial acetic acid (accounting for 10% by weight of fatty acid methyl ester) into the reactor in corresponding proportions, heat up, start stirring and operate a closed cooling cycle device, and heat up to 40°C to stop heating , open the cooling water valve of the reaction kettle, drip hydrogen peroxide (accounting for 35% of the mass proportion of fatty acid methyl ester) at a speed of 55g / s, the temperature of the reaction solution is controlled at 40-60°C, and the dropping time is 3 hours, and the hydrogen peroxide dripping ends Afterwards, heat preservation and reflux for 3 hours to ensure that the epoxidation reaction is sufficient, wash, neutralize, and distill under reduced pressure for 1.5 hours to the thick product of epoxy plasticizer, stop stirring and close the closed cooling cycle device, and dehydrate under reduced pressure to obtain non-toxic Environmentally friendly epoxy plasticizer.

Embodiment 3

[0035] In a 3000L reactor, put fatty acid methyl esters and glacial acetic acid (accounting for 15% by mass of fatty acid methyl esters) into the reactor in corresponding proportions, heat up and start stirring, heat up to 43°C to stop heating, and open the cooling water valve of the reactor , drip hydrogen peroxide (accounting for 35% of methyl formate mass proportion) with the speed of 20g / s, the temperature of reaction solution is controlled at 40-60 ℃, and the time of dropping is 6 hours. The oxidation reaction is sufficient, and the crude product of the epoxy plasticizer is washed with water, neutralized, distilled under reduced pressure for 2.5 hours, and dehydrated under reduced pressure to obtain a non-toxic and environment-friendly epoxy plasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com