A preparation method of disodium 5'-inosinate by using crystallization process

A technology of disodium inosinate and inosinic acid, which is applied in the field of preparing disodium 5'-inosinate, can solve the problems of large amount of hydrophilic organic solvent and the like, and achieve the effect of reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Establishment of 5'-disodium inosinate crystallization conditions

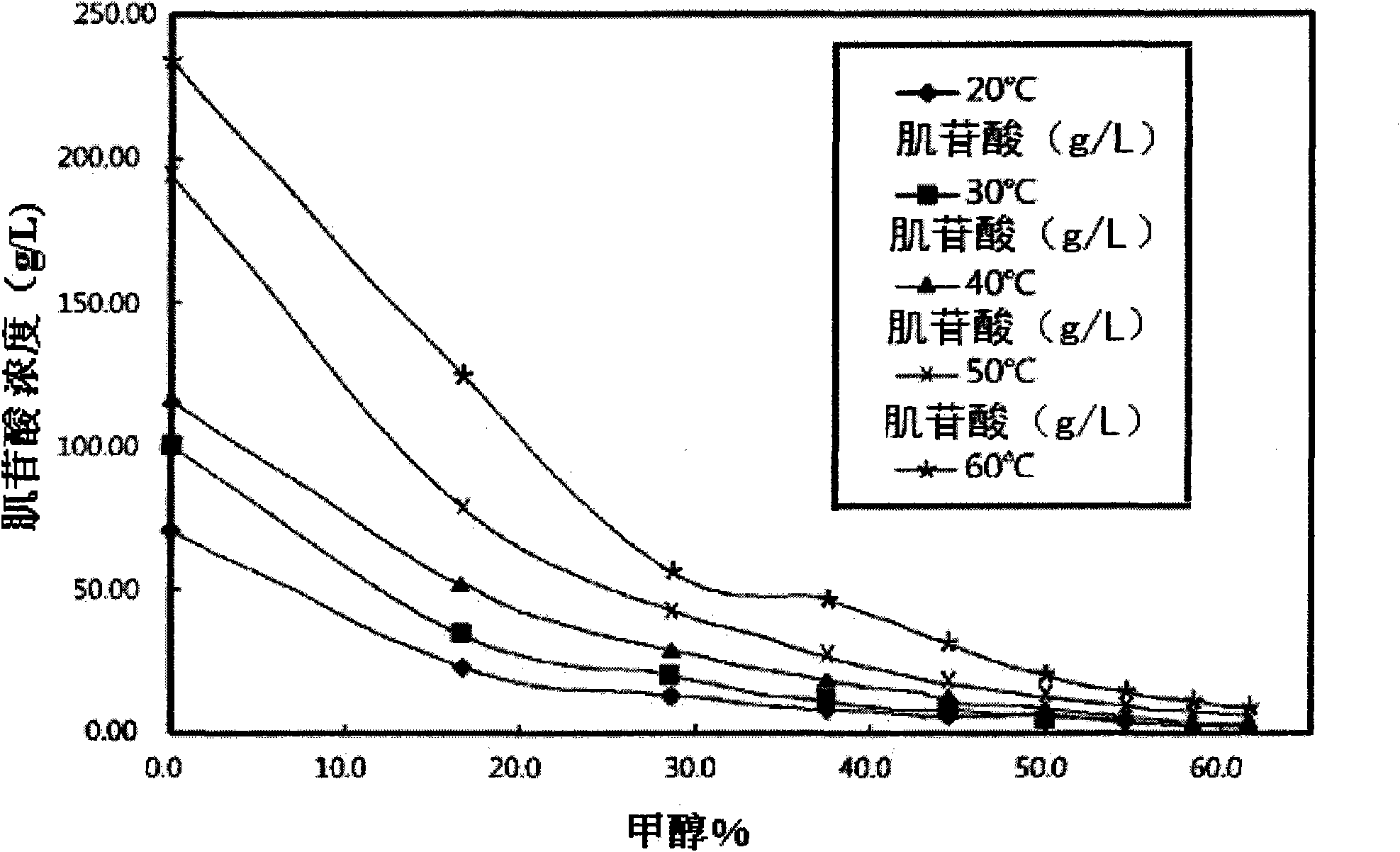

[0029] In order to establish the optimal crystallization conditions of disodium 5'-inosinate, the solubility of disodium 5'-inosinate is determined by temperature and organic solvent. The solubility of disodium 5'-inosinate was determined by HPLC, and the concentration (% v / v) of the organic solvent in the total solution was adjusted to be 0-60% ( figure 1 ).

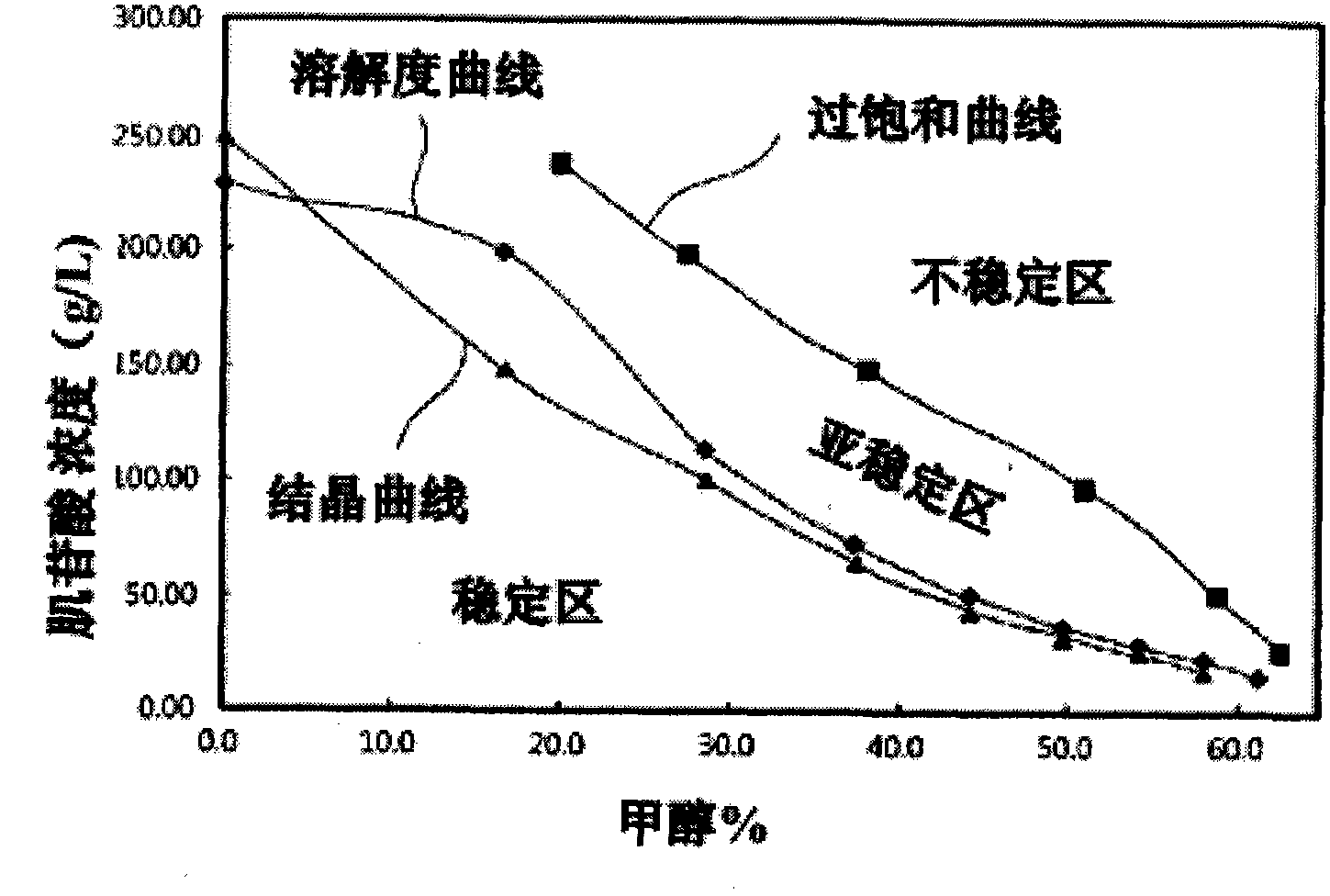

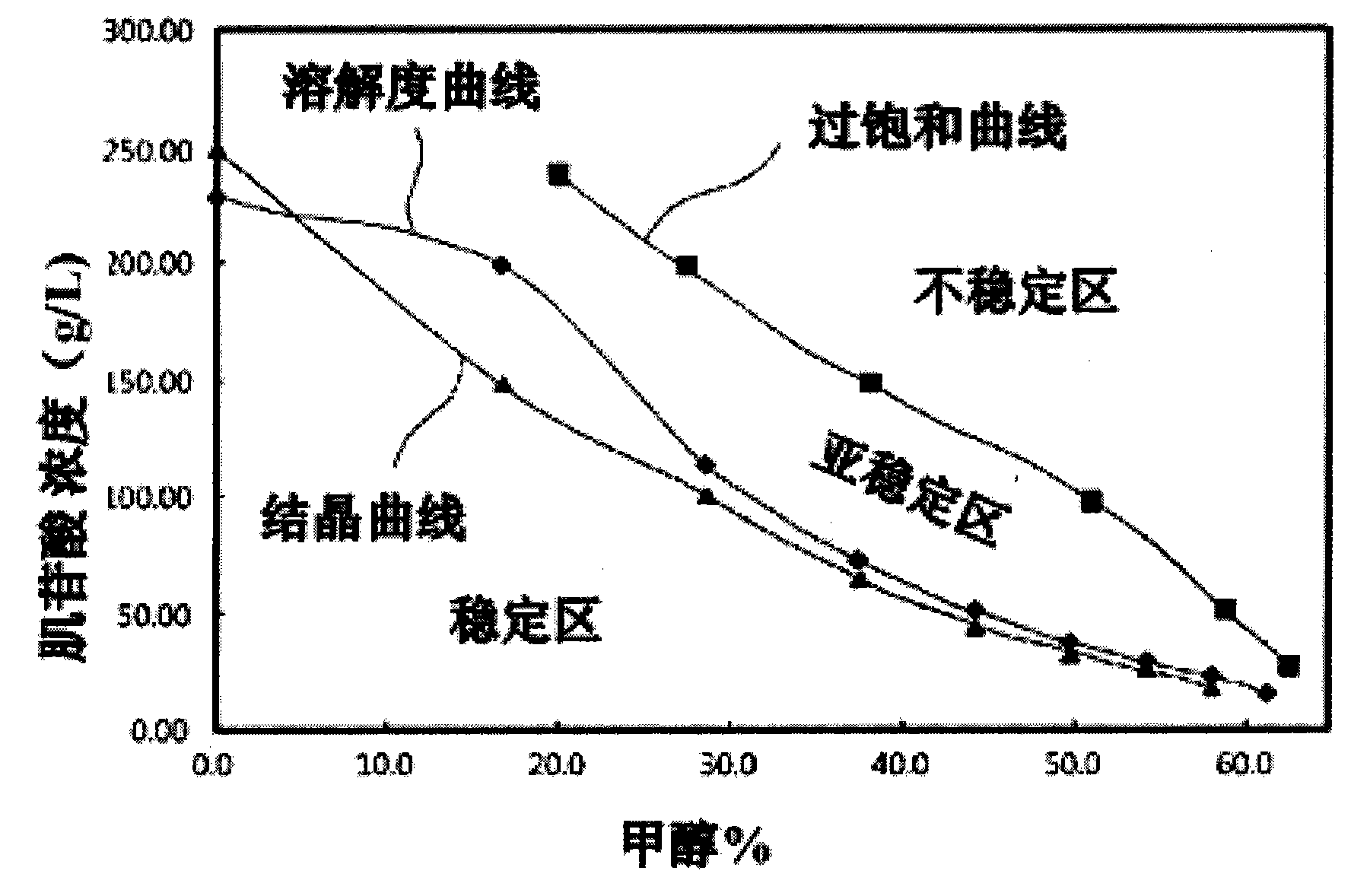

[0030] The supersaturation curve was obtained by measuring the solubility of disodium 5' inosinate solution in the actual fermentation broth using an online particle size analyzer; recording the temperature-based, at each organic solvent concentration (% v / v) The point where the nucleation suddenly increases and the point where the nucleation suddenly disappears when the temperature increases; the number of particles and the average size and concentration of particles are analyzed every minute. Through experiments, through the te...

Embodiment 2

[0032] Embodiment 2: realize the crystallization process of culture concentrate by the crystallization of organic solvent

[0033] Based on the results of Example 1, prepare 5'-disodium inosinate from the fermentation broth according to the method as follows:

[0034] Step 1: Cultivation of strains and isolation of bacteria

[0035] Inosinic acid-producing Corynebacteriun glutamicum CJM107 (KCCM-10227) strain is used in the present invention.

[0036] The strain was inoculated in 1L containing 46g glucose, 30g fructose, 10g yeast extract, 18gKH 2 PO 4 , 42g K 2 HPO 4 , 6g urea, 10g MgSO 4 ·7H 2O, in the fermented liquid of 30 μ g biotin and 5 mg thiamine hydrochloride, be exposed to pH 6-8, cultivate in the 18L medium of temperature 30-32 ℃ for 140 hours, until the concentration of inosinic acid in the fermented liquid reaches 5-10 %. The concentration of inosinic acid in the cultured broth was measured by HPLC. Any strains other than coryneform bacteria for producing...

Embodiment 3

[0052] Example 3: Crystallization of concentrated fermented broth by cooling crystallization

[0053] This embodiment 3 is carried out according to the same method as in steps 1 to 3 in embodiment 2. Step 4 and subsequent steps are explained below.

[0054] Step 4: Heating

[0055] Similar to Example 1, the temperature of the crystallization tube was heated to 60° C. to keep the liquid in a state where all the crystals were melted.

[0056] Step 5: Cool

[0057] As a result of the heating step, the liquid cools without crystallization. The liquid cooled at a uniform rate down to 20 °C within 5 hours, and the crystal production rate was at the level of 70% of the supernatant concentration.

[0058] Step 6: Add organic solvent and separate crystals

[0059] To extract disodium 5'-inosinate in crystalline form in the supernatant, 150 mL of 95% (v / v) aqueous methanol was added within 2 hours. During the addition of methanol, the temperature of the precipitation tube was...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap