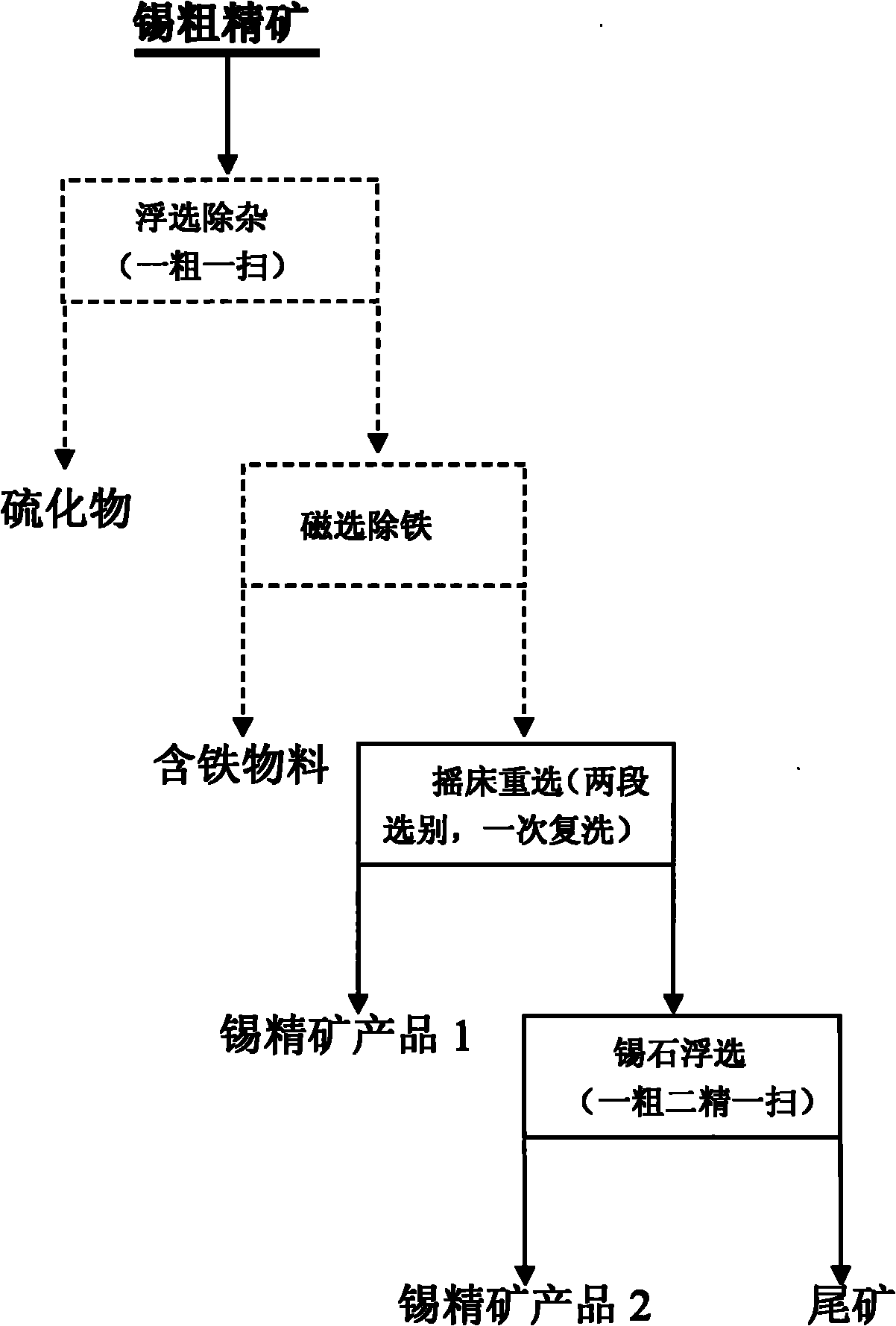

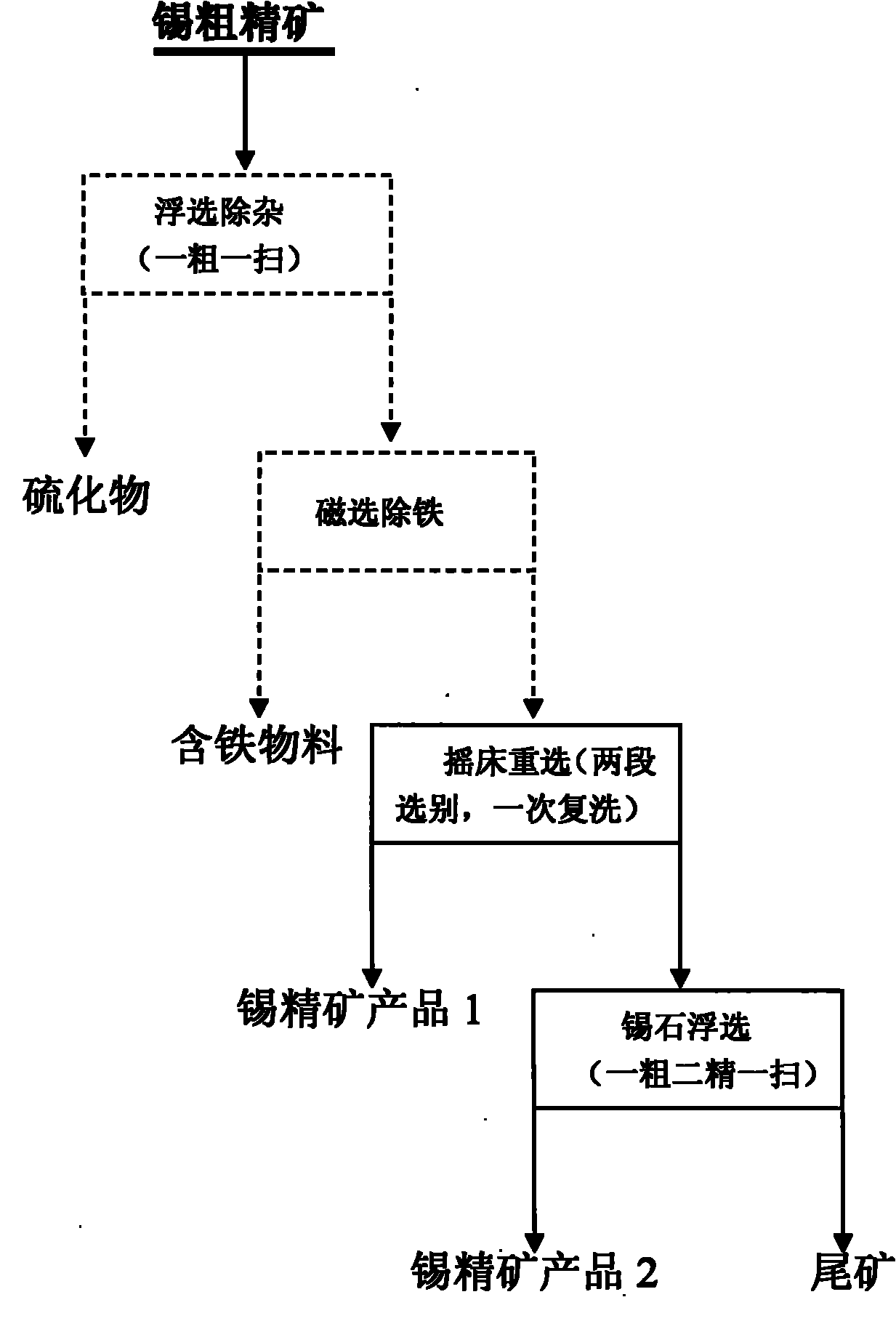

Improved method for cleaning tin rough concentrate

A technology of rough concentrate and tin concentrate, which is applied in the field of joint processing of tin coarse concentrate, can solve the problems of unrecycled tin, low grade of rich and medium ore, poor economic benefits, etc., and achieves great application and promotion value. , the effect of improving the recovery rate and improving the economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Chemical composition of tin rough concentrate, Sn8.37%, Fe12.02%, S3.56%.

[0015] Process conditions and results: tin coarse concentrate is slurried to a concentration of 25% by weight, after two stages of separation on a shaking table and one rewashing, a qualified tin concentrate 1 with a tin content of 45.5% is produced, and the tin recovery rate is 85.3% . Shaking table gravity separation tailings are fed into cassiterite flotation after grinding (-400 mesh accounts for 65%), desliming, impurity removal, and slurry adjustment. Join Na 2 CO 3 The solution was stirred, and the pH value of the slurry was adjusted to 9. Add 120g of sodium silicate + CMC combination inhibitor, 1200g of YY-1 cassiterite collector, and 30g of No. 2 oil per ton of dry ore. In one sweep, the tin concentrate product 2 containing 36.5% tin was obtained, and the tin recovery rate accounted for 12.5% of the total ore supply. The sum of tin concentrate products 1 and 2 has a tin grade of 4...

Embodiment 2

[0017] Chemical composition of tin rough concentrate, Sn7.46%, Fe15.23%, S7.46%.

[0018] Technological conditions and results: tin coarse concentrate is adjusted to a concentration of 40% by weight, and sulfur is removed by flotation with a mechanical agitation flotation machine. For each ton of dry ore, 500g of copper sulfate, 100g of ethyl butyl mixed xanthate, and 2 No. oil 30g, the desulfurized product contains 0.9% sulfur. The sulfur-removed product is sorted in two stages on a shaking table and washed again once, and a qualified tin concentrate 1 with a tin content of 43.18% is produced, and the tin recovery rate is 84.98%. Shaking table gravity separation tailings are fed into cassiterite flotation after grinding (-400 mesh accounts for 70%), desliming, impurity removal, and slurry adjustment. Join Na 2 CO 3 The solution is stirred, and the pH value of the slurry is adjusted to 10. Add 150g of water glass + CMC combination inhibitor, 1000g of YY-1 cassiterite collec...

Embodiment 3

[0020] Chemical composition of tin rough concentrate, Sn10.56%, Fe10.23%, S2.55%.

[0021] Process conditions and results: tin coarse concentrate is slurried to a concentration of 25% by weight, after two-stage separation on a shaking table and one-time rewashing, qualified tin concentrate 1 with a tin content of 45.53% is produced, and the tin recovery rate is 86.02% . Shaking table gravity separation tailings are fed into cassiterite flotation after grinding (-400 mesh accounts for 75%), desliming, impurity removal, and slurry adjustment. Join Na 2 CO 3 The solution was stirred, and the pH value of the slurry was adjusted to 9.5. For each ton of dry ore, 100g of sodium silicate + CMC combined inhibitor, 800g of YY-1 cassiterite collector, and 30g of No. 2 oil were added to each ton of dry ore. In one sweep, a tin concentrate product 2 containing 36.5% tin was obtained, and the tin recovery rate accounted for 11.14% of the total ore supply. The sum of tin concentrate prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com