Novel method for producing dihydromyrcenol

A technology of dihydromyrcenol and dihydromyrcene, which is applied in the field of continuous production of dihydromyrcenol, can solve the problems of solid catalyst pulverization, decreased reaction rate, and long reaction time, so as to improve selectivity and reduce equipment Corrosion, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

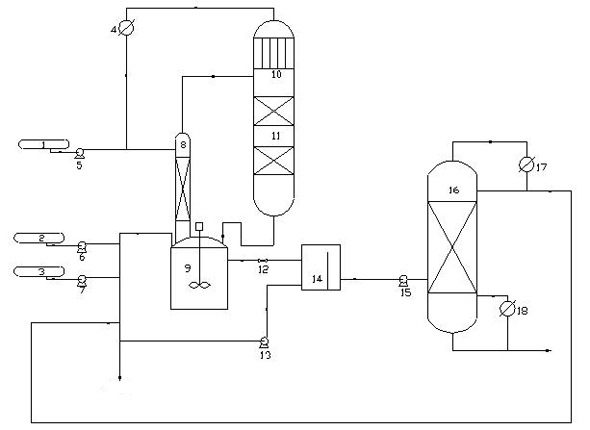

Embodiment 1

[0029] The reaction tower 11 is filled with Amberlyst 35 cation exchange resin, and the rectification towers 8 and 16 are filled with high-efficiency packing of BX corrugated wire mesh. Send deionized water and dioxane solvent into the evaporation kettle 9 according to the volume ratio of 1:2 through the pump 6 and the pump 7. The total addition is 0.8 of the volume of the evaporation kettle. After the feeding, stop the pump 6 and the pump 7 and start the evaporation. Stirring and heating of the still; the reflux rate of the control separation tower 8 is 1 / 8 of the total evaporation capacity. After the separation tower 8 and the reaction tower 11 are all refluxed normally, start the pump 5 and add dihydromyrcene and dihydromyrcene continuously to the reaction device. The purity of myrcene is 85% (wt%). The temperature of the reaction tower is controlled at 85°C. After 3 hours of feeding, the valve 12 is opened, and part of the oil-water mixture is pumped out to the stratifier 1...

Embodiment 2

[0031]Similar to the operation method of Example 1, the difference is that the solvent is isopropanol, the volume ratio of the solvent to deionized water is 1:1, and the HZSM-5 zeolite catalyst bundled in the reaction tower is used to solve the problem of powder The problem of packing zeolite in a fixed bed. Dihydromyrcene in the evaporator: water: solvent = 1:1:1. Other operating steps are the same as in Example 1, and the single pass conversion rate of this process is 57 ~ 58%, and the selectivity is 95%.

Embodiment 3

[0033] Similar to the operation method of Example 1, the difference is that butanone is used as the solvent, the volume ratio of the solvent to deionized water is 1:1, and the dihydromyrcene in the evaporation kettle: water: solvent = 1:1:1. Other operating steps are the same as in Example 1, and the single pass conversion rate of this process is 55 ~ 56%, and the selectivity is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com