Method for preparing lutein oleoresin microcapsule

A technology of oleoresin and lutein, which is applied in the field of preparing lutein oleoresin microcapsules, can solve the problems affecting the solubility and stability of lutein microcapsules, poor protection effect of capsule materials, and large emulsion particle size, etc. Coloring and nutritional health effects, overcoming narrow application range, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

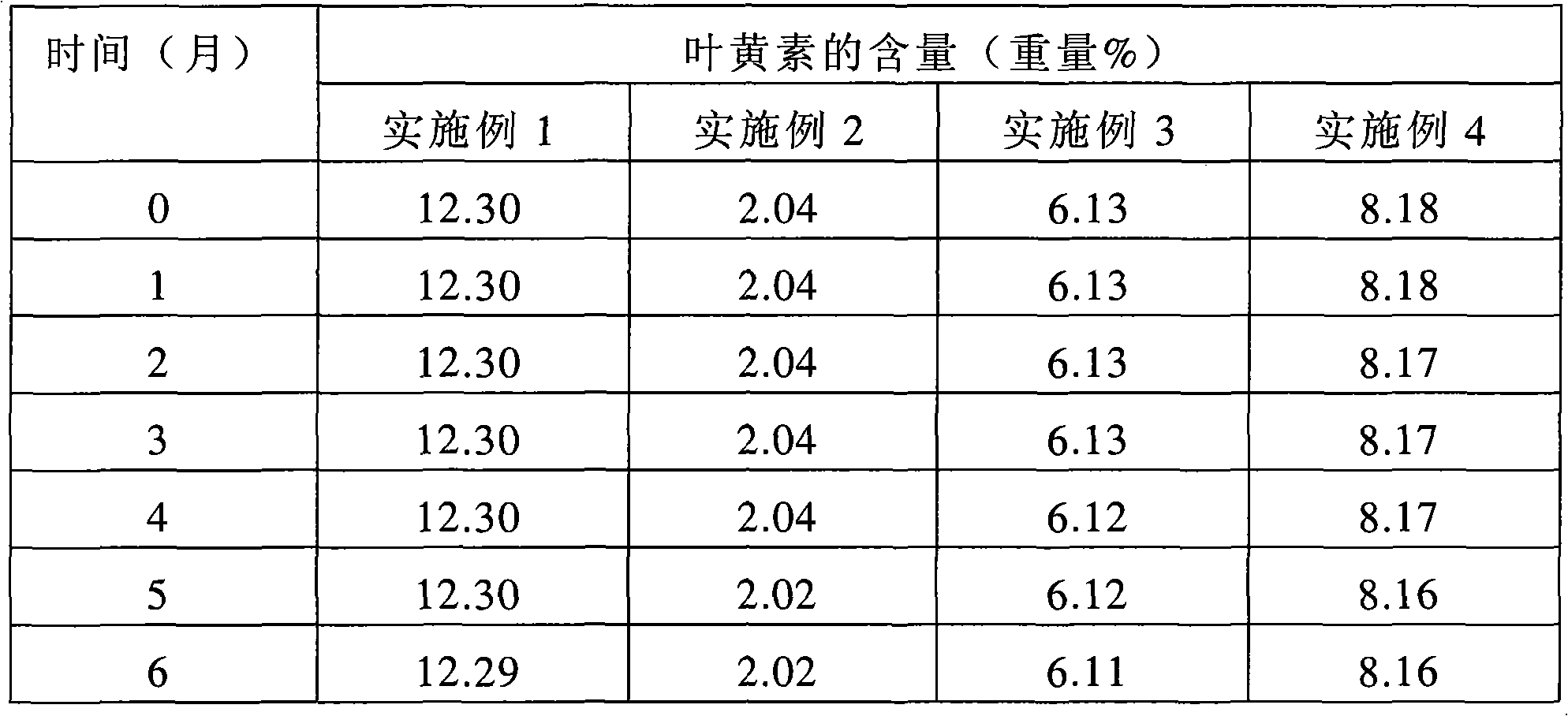

Embodiment 1

[0025] Lutein oleoresin microcapsules were prepared from lutein oleoresin (the content of lutein was 206g / kg lutein oleoresin). The lutein content is determined according to the American AOAC standard.

[0026] Heat 60g of the core material lutein oleoresin to 30°C under stirring, add 5g of sucrose ester, stir until dissolved, and obtain the core material phase. Add 24g of gelatin to 72mL of water, heat to 90°C, and stir to dissolve the gelatin. Add 8g of sodium caseinate and 3g of citric acid, stir until dissolved, and obtain the capsule material phase. The core material phase and the capsule material phase are mixed, emulsified and homogenized by a high-pressure homogenizer at 80 MPa to form an emulsion, and the particle size of the emulsion reaches 200 nm. Under the conditions of an inlet air temperature of 210° C. and an outlet air temperature of 110° C., the emulsion is dried in a spray drying tower to obtain lutein oleoresin microcapsule powder.

[0027] 82.3 g of ora...

Embodiment 2

[0031] Lutein oleoresin microcapsules were prepared from lutein oleoresin (the content of lutein was 206g / kg lutein oleoresin).

[0032] Heat 10 kg of core material lutein oleoresin to 70° C. under stirring, add 0.5 kg of phospholipid, stir until dissolved, and obtain the core material phase. Add 88L of water to 88kg gum arabic, heat to 50°C, stir to dissolve the gum arabic. Add 1 kg of casein acid and 0.5 kg of sodium dihydrogen phosphate, stir until dissolved, and obtain the capsule material phase. The core material phase and the capsule material phase are mixed, emulsified and homogenized by a high-pressure homogenizer at 20MPa to form an emulsion, and the particle size of the emulsion reaches 350nm. Under the conditions of an inlet air temperature of 160°C and an outlet air temperature of 70°C, the emulsion is dried in a spray drying tower to obtain lutein oleoresin microcapsule powder.

[0033] Obtain 96.7kg orange red lutein oleoresin powder by this method, wherein the...

Embodiment 3

[0037] Lutein oleoresin microcapsules were prepared from lutein oleoresin (the content of lutein was 206g / kg lutein oleoresin).

[0038] Heat 30 kg of core material lutein oleoresin to 50° C. under stirring, add 1 kg of monoglycerides of fatty acids, stir until dissolved, and obtain the core material phase. Add 88L of water to 45kg of modified starch and 20kg of dextrin, heat to 50°C, and stir to dissolve the modified starch and dextrin. Add 2.5 kg of potassium caseinate and 1.5 kg of potassium dihydrogen phosphate, stir until dissolved, and obtain a capsule material phase. The core material phase and the capsule material phase are mixed, emulsified and homogenized by a high-pressure homogenizer at 40 MPa to form an emulsion, and the particle size of the emulsion reaches 230 nm. Under the conditions of 200°C inlet air temperature and 100°C outlet air temperature, the emulsion is dried in a spray drying tower to obtain lutein oleoresin microcapsule powder.

[0039]Obtain 97.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com