Surface-treated metal materials, method of treating the surfaces thereof, resin-coated metal materials, cans and can lids

一种金属材料、表面处理的技术,应用在薄料处理、运输和包装、电解无机材料镀层等方向,能够解决密合性低下、密合性低、树脂拉毛等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0280] 1. Preparation of surface-treated metal plates

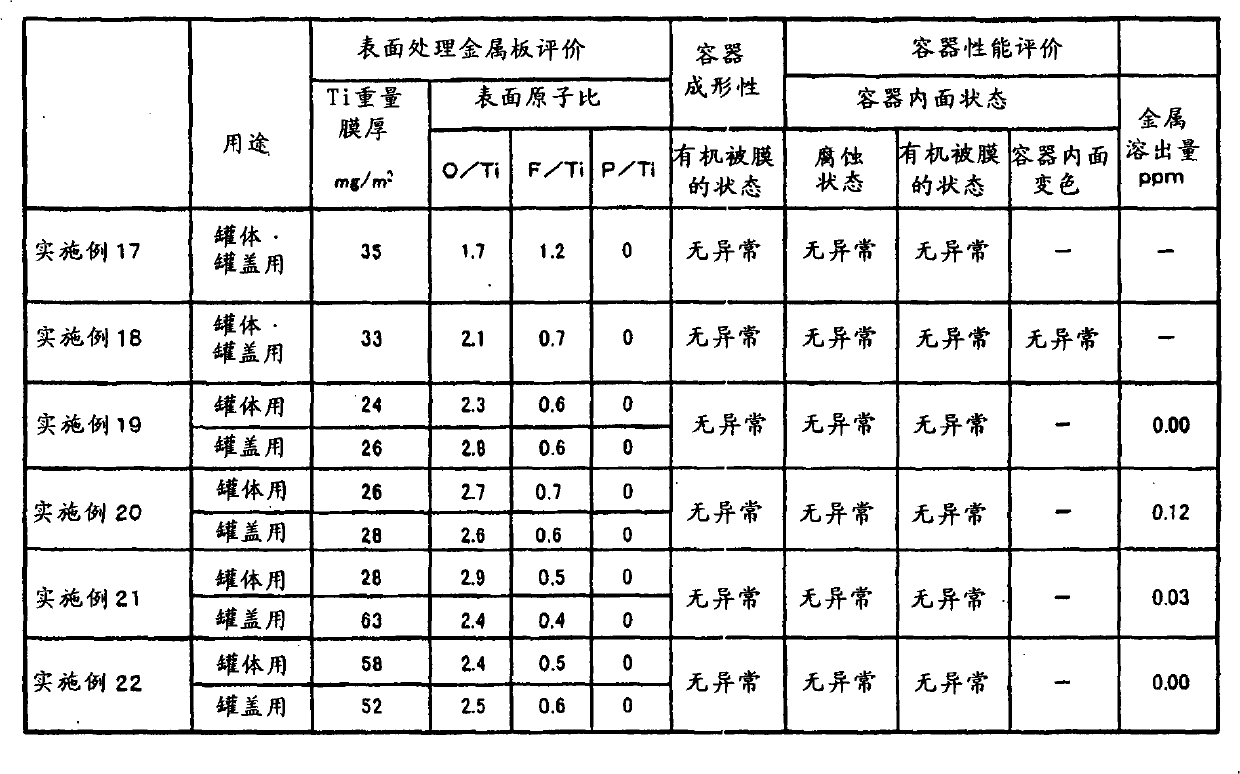

[0281] A 0.25 mm thick JIS5021H18 aluminum alloy plate was used as the metal plate, and the degreasing agent 322N8 (manufactured by Japan Peinto Co., Ltd.) was used. According to the usual method, it was treated in a bath at 70°C for 10 seconds, washed with water, and then dipped in 1% sulfuric acid at 40°C. 5 seconds, wash with water, wash with pure water, and perform pretreatment. Next, while stirring in the treatment bath shown in A of Table 2 at a bath temperature of 45°C, an indium oxide-coated titanium plate arranged at a position of 17 mm between the electrodes was used as an anode, and at 10 A / dm 2 Under the current density, the operation of energizing for 0.4 seconds-stopping for 0.6 seconds was repeated four times, cathodic electrolysis was performed intermittently, and post-treatments of running water washing, pure water washing and drying were immediately performed to obtain a surface-treated aluminum plate. ...

Embodiment 2

[0291] Set the current density to 5A / dm 2 , Repeat the operation of energizing for 0.6 seconds-stopping for 0.4 seconds 8 times, and perform surface treatment, resin coating, cap production and evaluation in the same manner as in Example 1.

Embodiment 3

[0293] Use the bath shown in B of Table 2 as the treatment bath, and set the current density to 7A / dm 2 , Surface treatment, resin coating, cap production, and evaluation were performed in the same manner as in Example 1 except that.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com