Steam methane reformer and hydrogen station having it using high performing metal fiber burner

A technology of steam reforming and metal fiber, applied in the field of hydrogen station, can solve the problems of reduced hydrogen station or reformer performance, reduced hydrogen production rate, easy damage to other components, etc., to improve hydrogen productivity, short flame length, stable heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

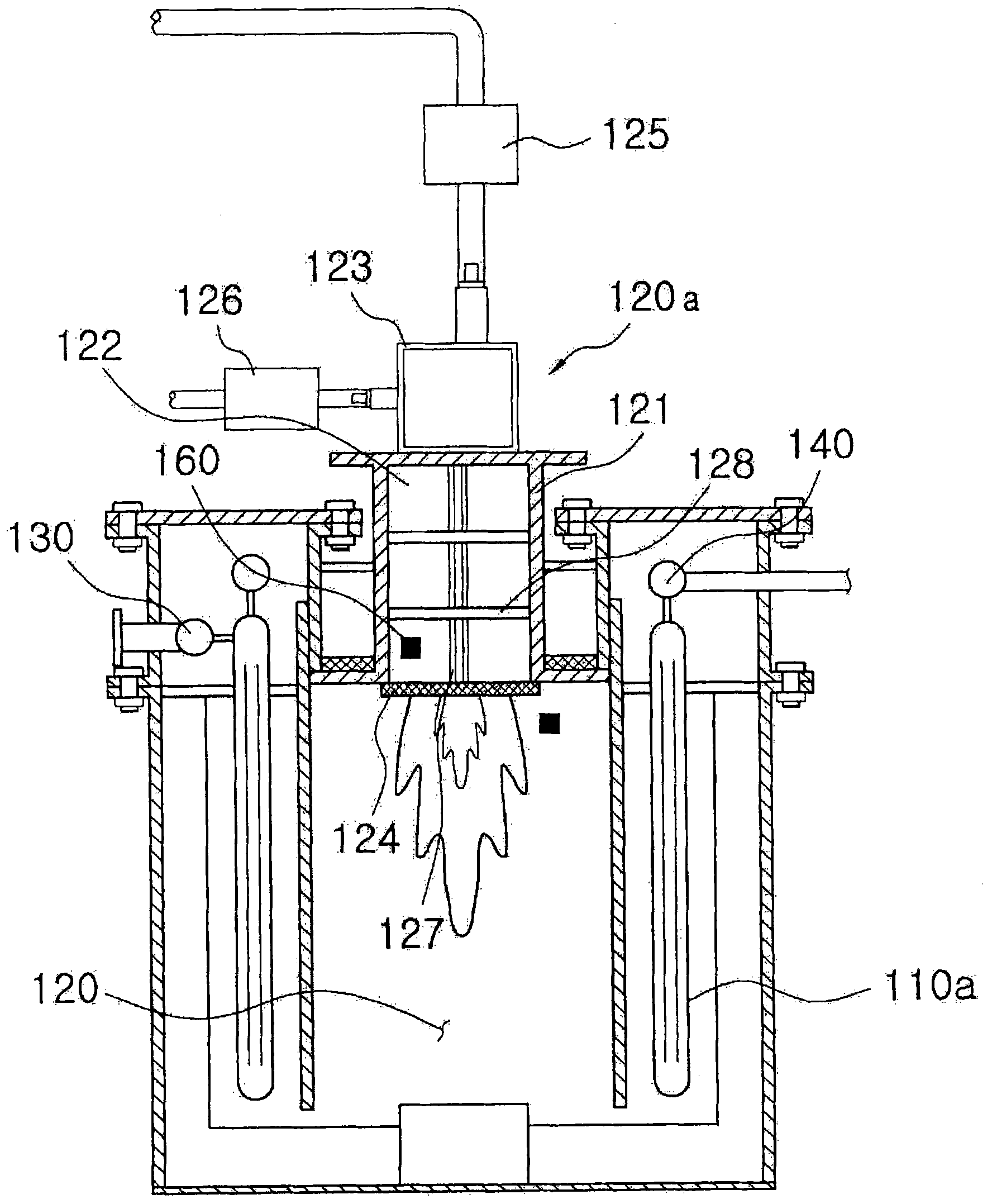

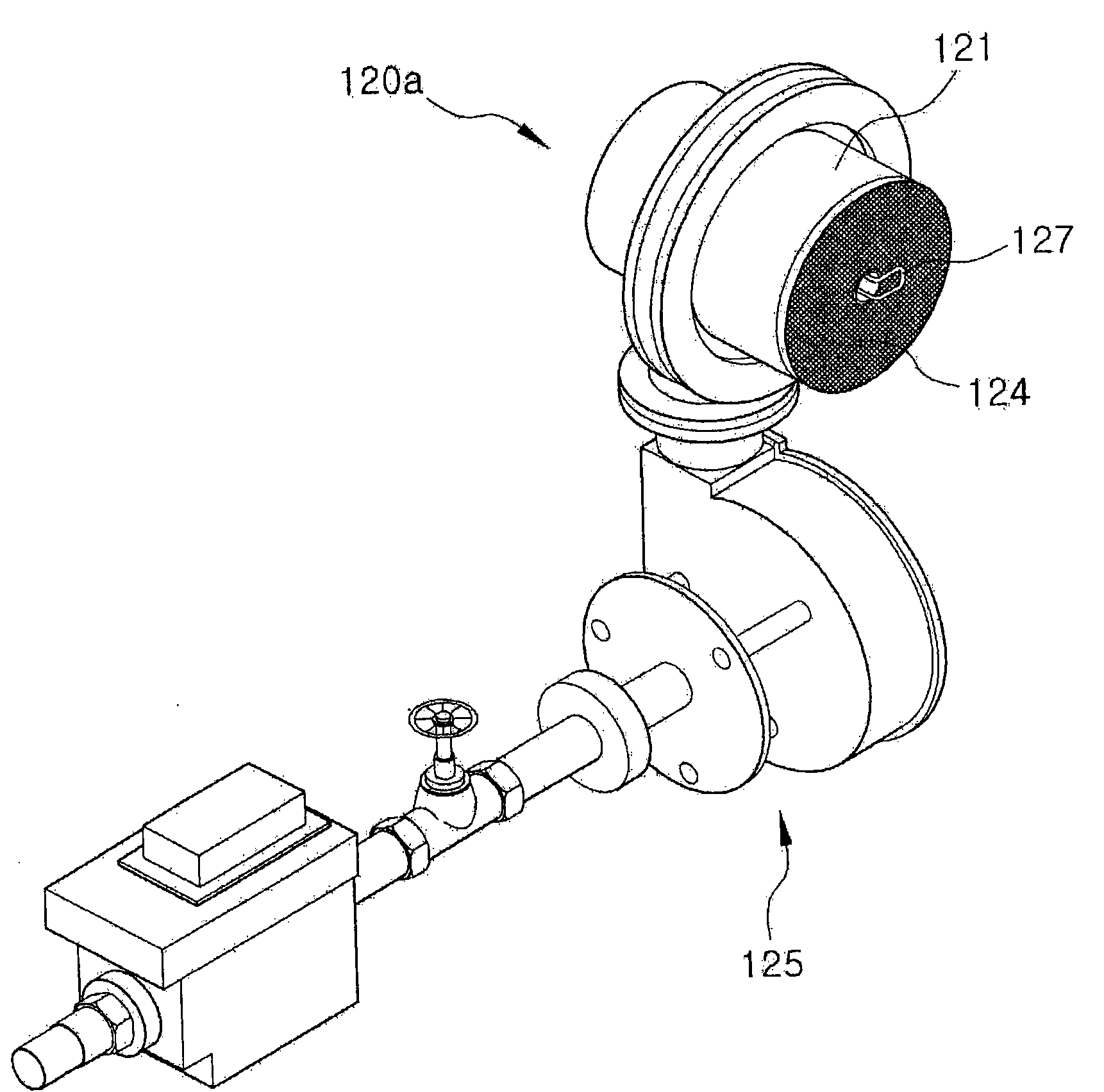

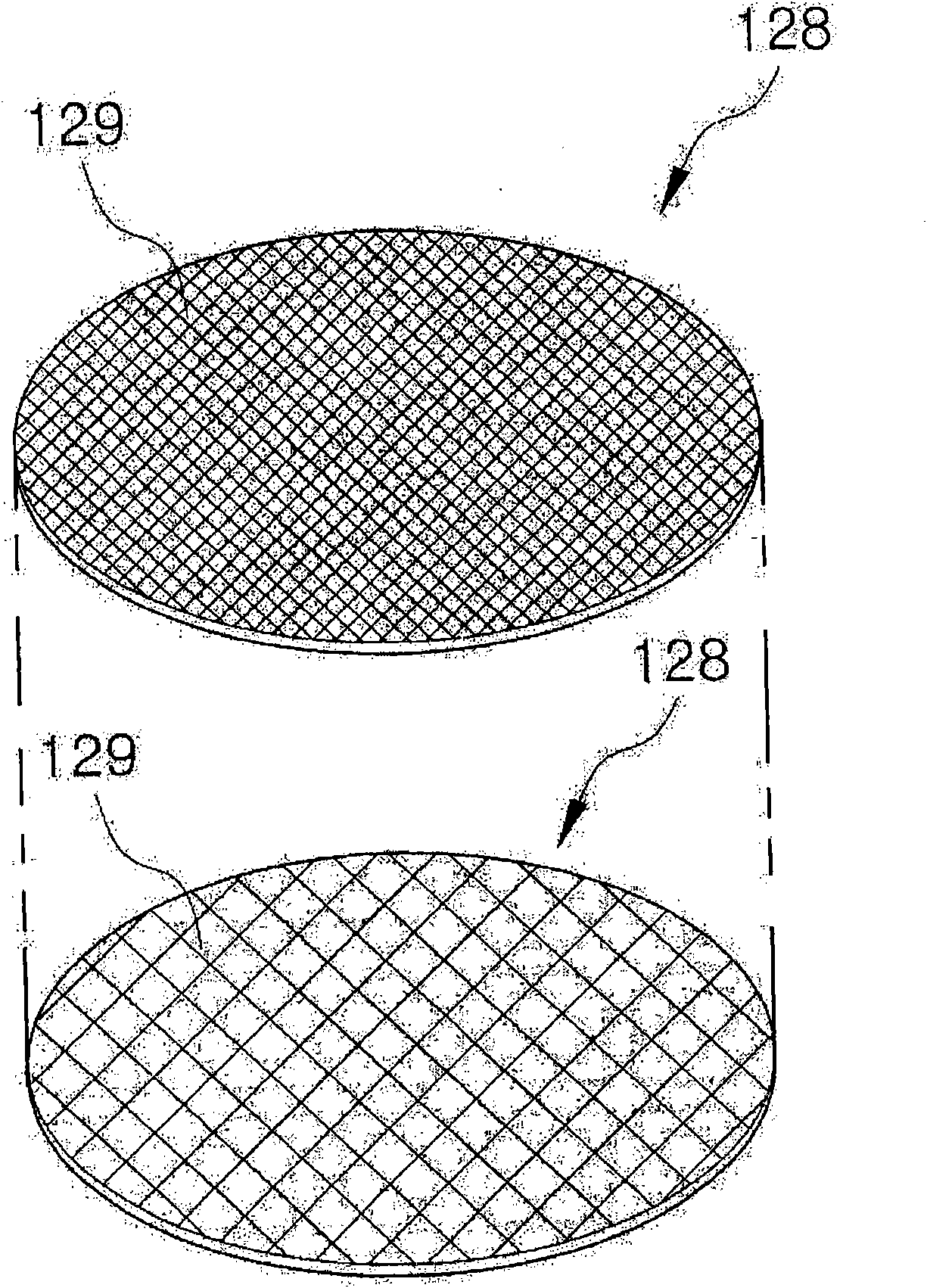

[0041] figure 1 is a cross-sectional view of a steam methane reformer 100 according to the present invention, figure 2 yes figure 1 A perspective view of the premixed metal fiber burner 120a of the steam methane reformer 100, image 3 is a perspective view of the anti-backfire device 128, Figure 4 It is a graph which shows the internal temperature of the combustion part 120 when the premixed metal fiber burner 120a is used.

[0042] The steam methane reformer 100 according to the present invention includes: a reforming part 110 generating hydrogen through a reforming reaction, and a combustion part 120 maintaining a high temperature required for the reforming reaction. The reforming section 110 is equipped with a plurality of reaction tubes 110a in which catalysts for steam reforming hydrocarbon materials and generating hydrogen are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com